High-power 3D integrated three-phase EMI filter

A filter and high-power technology, applied in the field of electronic devices, can solve the problems of increasing filter volume, low power density, and difficulty in heat dissipation, and achieve the effects of increasing insertion loss, reducing volume, and improving heat dissipation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

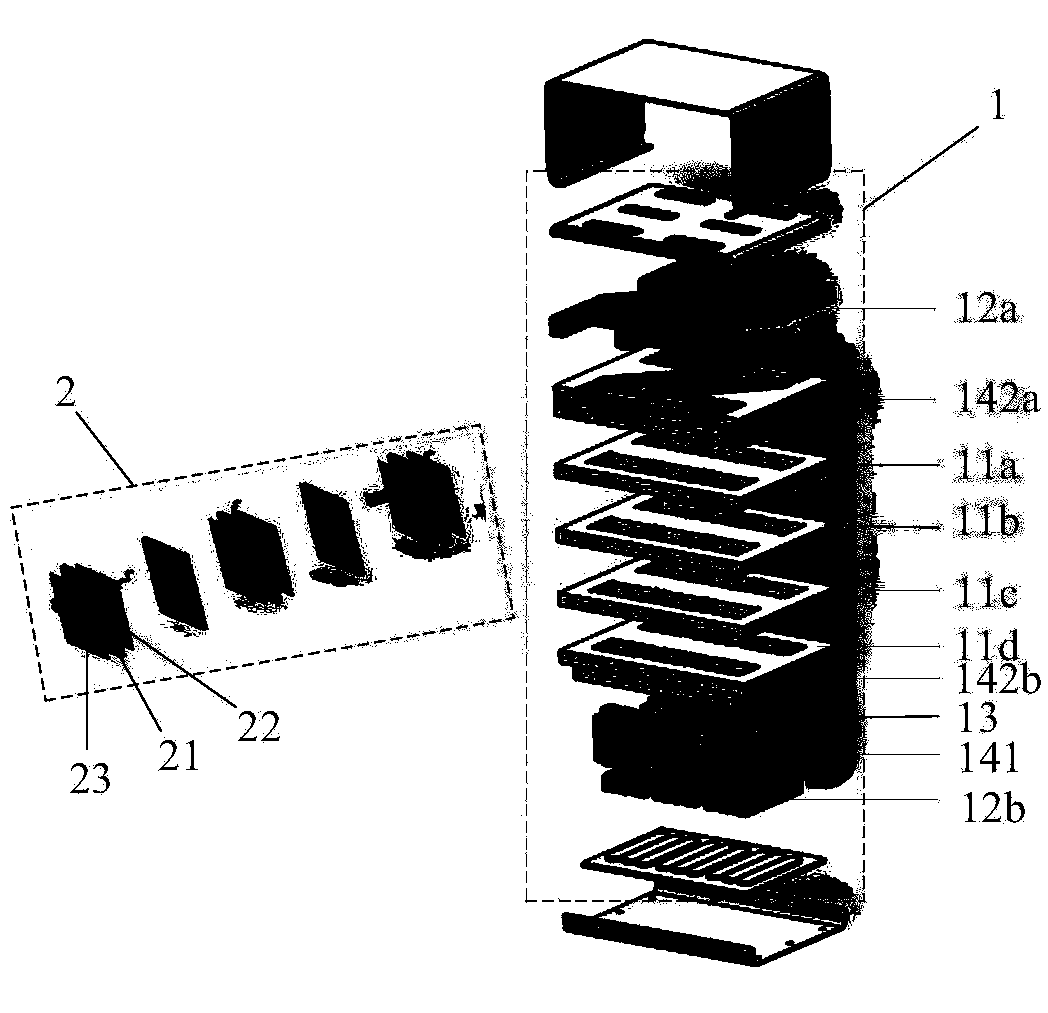

[0034] In order to more clearly illustrate the technical solutions in the embodiments of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

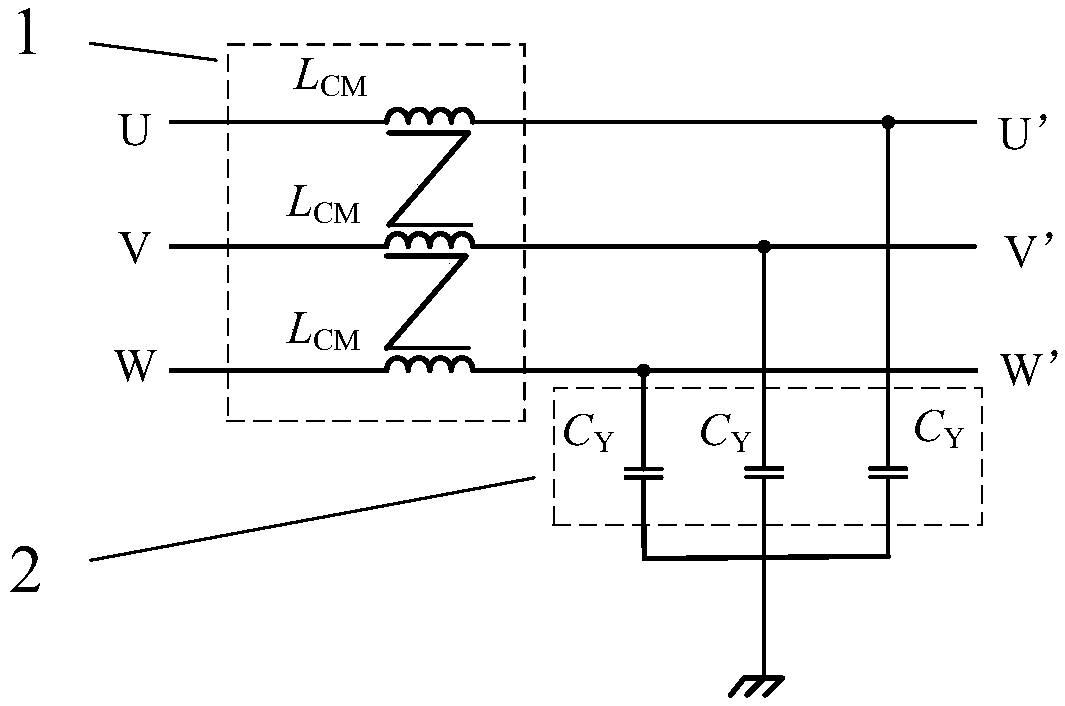

[0035] refer to figure 1 , the high-power 3D integrated three-phase EMI filter circuit of the present invention includes a three-phase planar common-mode inductor 1 and three flat-plate common-mode capacitors 2, and each phase self-inductance L of the three-phase planar common-mode inductor 1 CM connected in series to the main circuit, each corresponding planar common mode capacitor C Y Connected between the main circuit and ground, L CM with C Y Constitutes an inverse Γ-type low-pass filter, forming a low-impedance path for the noise signal. When the noise signal flows through the filter from the U, V, and W three-phase lines, it will be filtered out through the low-impedance path without being transmitted. To U', V', W' phase line side.

[0036...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com