Method for calculating internal pressure distribution of asphalt concrete pore material in gas seepage process

A technology of pore material and internal pressure, which can be used in calculations, special data processing applications, instruments, etc., and can solve problems such as affecting the service life of the overall structure and deblunting of steel bars.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

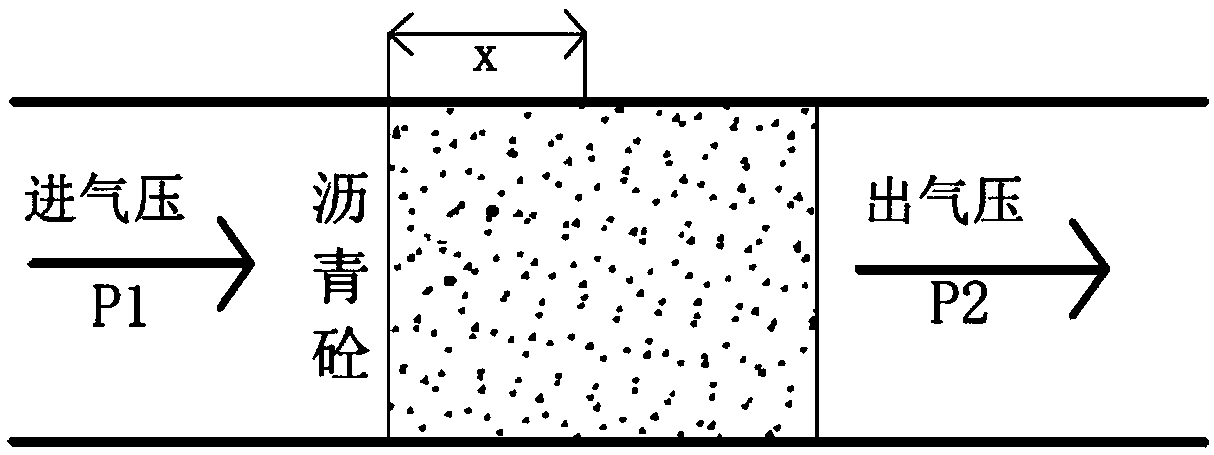

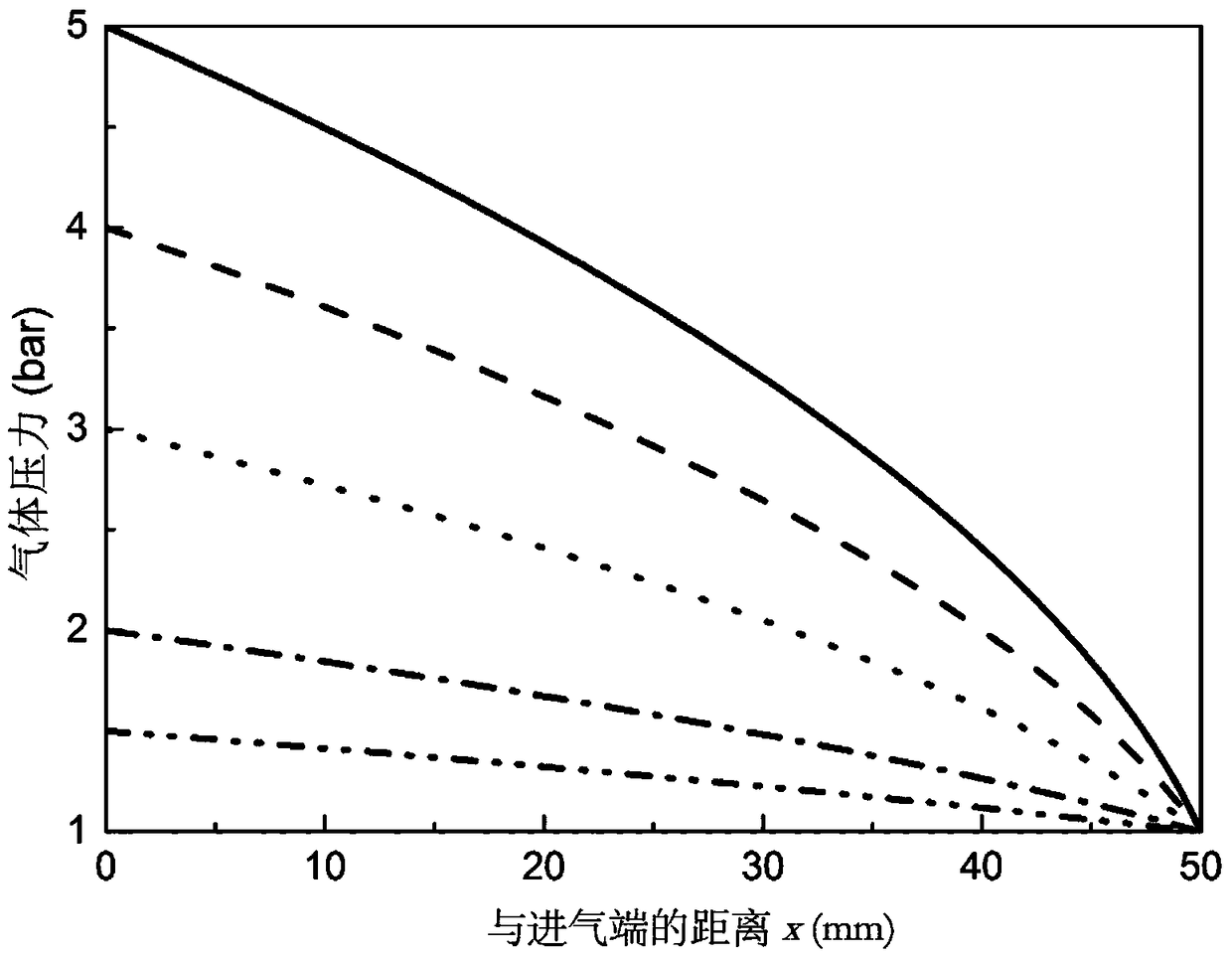

[0056] Let the air pressure P at the inlet end be maintained 1 >1bar, outlet air pressure P 2 It is 1 atmospheric pressure, approximately 1 bar; such as figure 2 As shown, from top to bottom are the inlet air pressure P 1 =5bar, 4bar, 3bar, 2bar, 1.5bar, outlet P 2 = 1bar, seepage length L = 50mm under the steady-state condition of the gas pressure distribution curve inside the porous material, from figure 2 It can be seen that when x=0, the gas pressure value is the air pressure P at the intake end 1 , when x=L, the gas pressure value is the air pressure value P at the gas outlet 2 , when x is between 0 and L, the gas pressure value changes according to formula (1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com