Torsion spring moment detection apparatus

A detection device and torsion spring technology, which is applied in the direction of measuring devices, force/torque/work measuring instruments, and testing of mechanical components, can solve the problems of torsion spring service life impact, armrest box wear, waste of time and energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

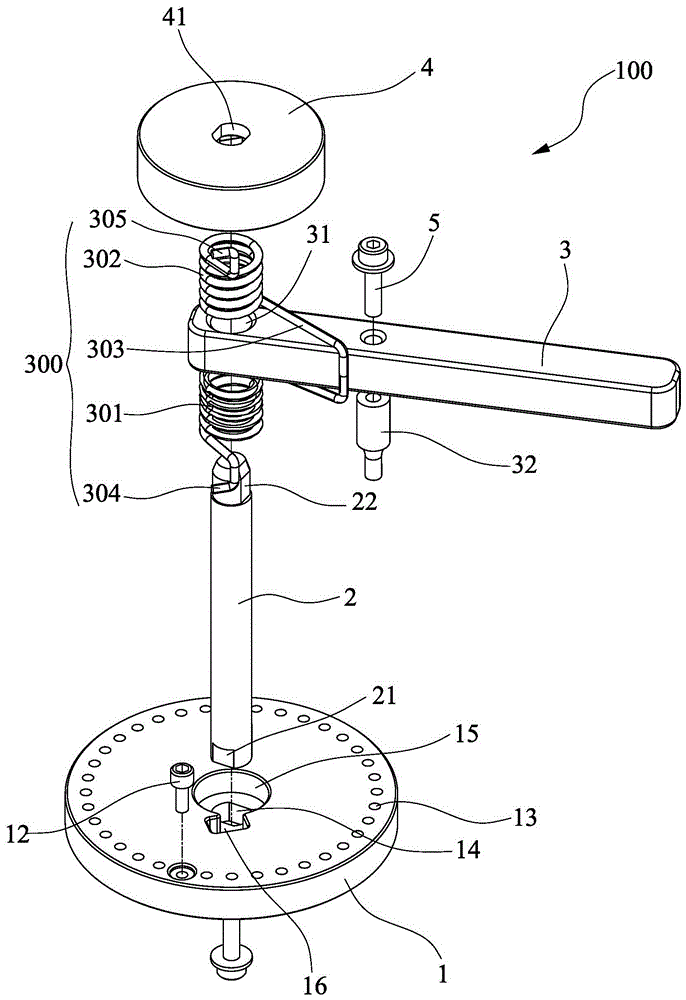

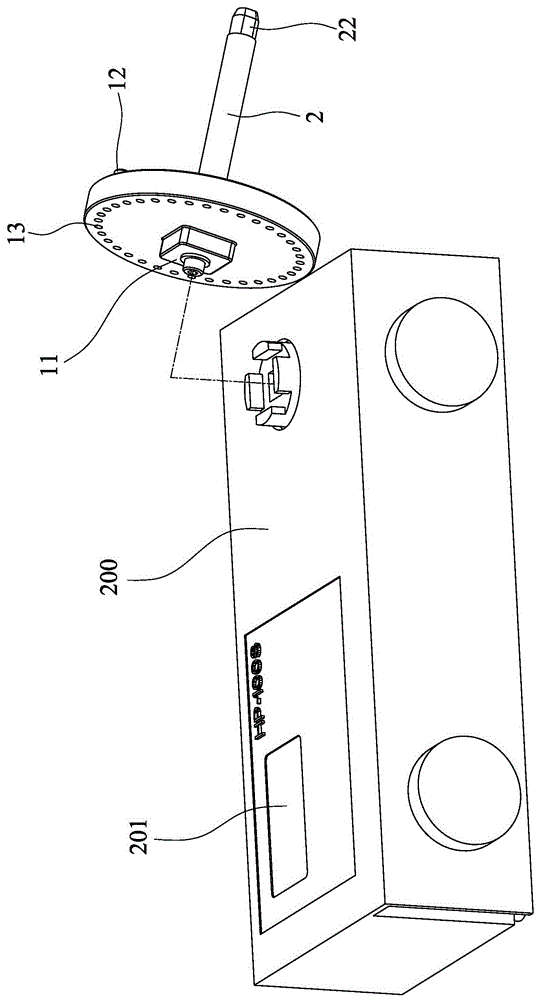

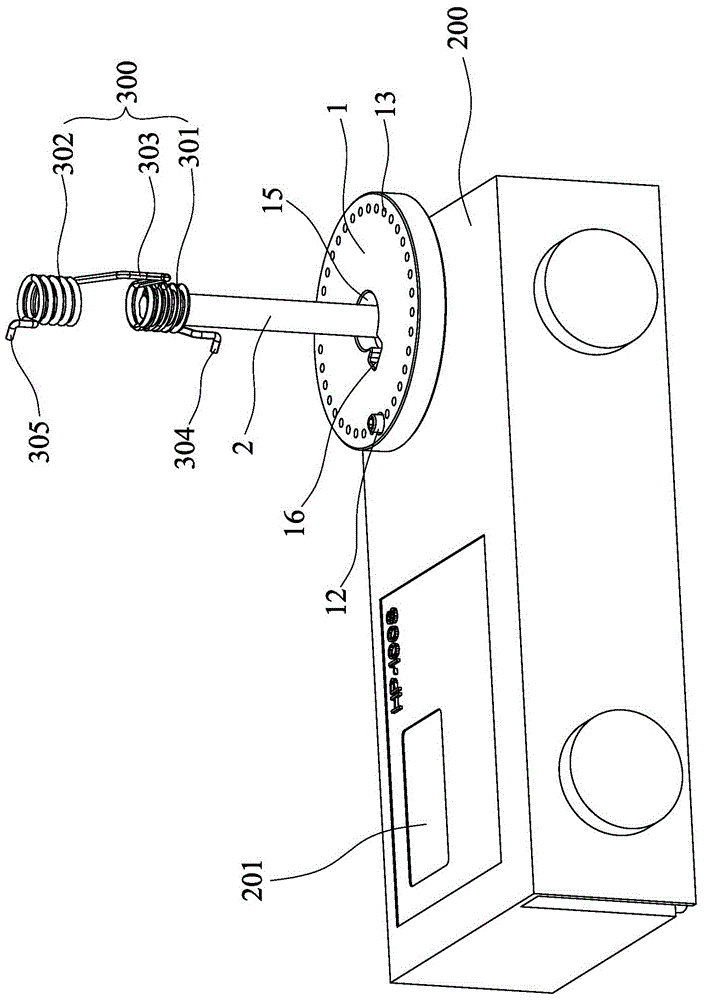

[0027] Such as figure 1 As shown, the present invention discloses a torsion spring torque detection device 100 , which is implemented in conjunction with a torsion meter 200 and a torsion spring 300 to be tested.

[0028] The torque meter 200 is an existing structure, and it has a display screen 201. The other structures of the torque meter 200 are not the focus of this case, and will not be repeated here.

[0029] The torsion spring 300 to be tested is a double torsion spring, including a first spring portion 301, a second spring portion 302, and a spring arm 303. The bottom end of the first spring portion 301 of the torsion spring to be measured forms a first positioning portion 304, A top end of the second spring portion 302 forms a second positioning portion 305 .

[0030] The torsion spring torque detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com