Simple device for detecting magnetic flux, and technology for detecting magnetic flux

A detection device and a technology of magnetic flux, applied in the direction of the size/direction of the magnetic field, can solve the problems of the compressor cannot be repaired, the detection result is complicated, the assembly difficulty is increased, etc., and the detection result is reliable and accurate, the operation process is simple, and the detection error is reduced. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

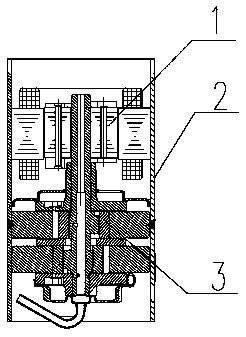

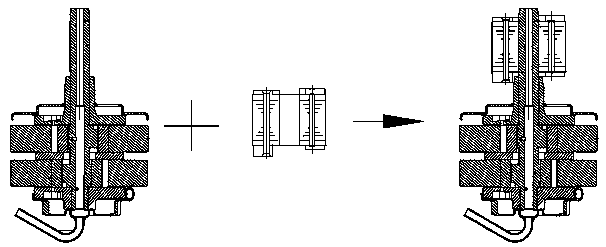

[0035] Such as figure 2 , Figure 4 with Figure 5 As shown, a simple magnetic flux detection device includes a frame 4, and the frame 4 is provided with a clamping module 5 and a detection module 8, and a driving module 6 for driving the clamping module 5 and the detection module 8 to move mutually; The clamping module 5 includes a pump body positioning jig 51, and a pressing assembly arranged around the pump body positioning jig 51; the pressing assembly includes at least two pump body pressing plates 53, and a motor for driving the pump body pressing plate 53 to move. drive member 52 .

[0036] Such as figure 2 , Figure 4 with Figure 5 As shown, the detection module 8 includes a standard magnetic coil and a signal processing unit 7 electrically connected to the standard magnetic coil. The detection module 8 also includes a standard coil positioning jig 81 and a standard coil pressing plate 82 arranged around the standard coil positioning jig 81. According to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com