Power equipment high-temperature early warning device

A technology of electric power equipment and early warning devices, which is applied in the direction of measuring devices, thermometers, and thermometers based on the expansion/contraction of materials, etc., can solve problems such as high cost and complex structure, and achieve large volume expansion coefficient, reduce sensitivity, and reduce damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

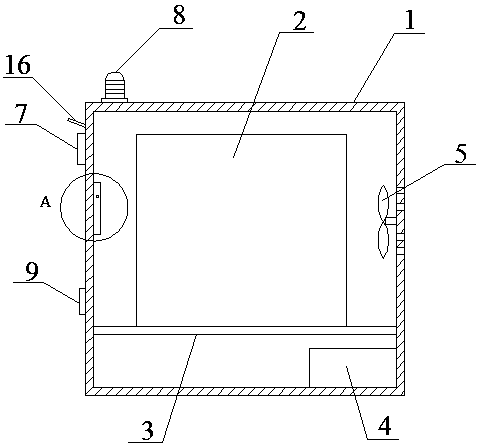

[0026] like figure 1 As shown, a high temperature early warning device for electric power equipment includes a cabinet body 1. A placement board 3 for placing power equipment 2 is arranged inside the cabinet body 1. A battery pack 4 is arranged under the placement board 3. The cabinet body 1 A fan 5 is arranged on the inside, ventilation holes are arranged on the side wall of the cabinet body 1, and a temperature control alarm device is provided on the cabinet body 1, and the temperature control alarm device includes a glass cylinder 6, a sound alarm 7, a warning light 8 and a switch 9. The glass cylinder 6 is provided with a cavity, the cavity is filled with alcohol 10, the alcohol 10 is provided with a floating plate 11, and a metal ball 12 is fixed on the floating plate 11, and the glass cylinder 6 Both sides of the upper end are provided with through holes, and wires are inserted into the through holes, and a metal sheet 13 is arranged on the upper part of the through hole...

Embodiment 2

[0030] like figure 2As shown, a high temperature early warning device for electric power equipment includes a cabinet body 1. A placement board 3 for placing power equipment 2 is arranged inside the cabinet body 1. A battery pack 4 is arranged under the placement board 3. The cabinet body 1 A fan 5 is arranged on the inside, ventilation holes are arranged on the side wall of the cabinet body 1, and a temperature control alarm device is provided on the cabinet body 1, and the temperature control alarm device includes a glass cylinder 6, a sound alarm 7, a warning light 8 and a switch 9. The glass cylinder 6 is provided with a cavity, the cavity is filled with alcohol 10, the alcohol 10 is provided with a floating plate 11, and a metal ball 12 is fixed on the floating plate 11, and the glass cylinder 6 Both sides of the upper end are provided with through holes, and wires are inserted into the through holes, and a metal sheet 13 is arranged on the upper part of the through hole...

Embodiment 3

[0035] like image 3 As shown, a high temperature early warning device for electric power equipment includes a cabinet body 1. A placement board 3 for placing power equipment 2 is arranged inside the cabinet body 1. A battery pack 4 is arranged under the placement board 3. The cabinet body 1 A fan 5 is arranged on the inside, ventilation holes are arranged on the side wall of the cabinet body 1, and a temperature control alarm device is provided on the cabinet body 1, and the temperature control alarm device includes a glass cylinder 6, a sound alarm 7, a warning light 8 and a switch 9. The glass cylinder 6 is provided with a cavity, the cavity is filled with alcohol 10, the alcohol 10 is provided with a floating plate 11, and a metal ball 12 is fixed on the floating plate 11, and the glass cylinder 6 Both sides of the upper end are provided with through holes, and wires are inserted into the through holes, and a metal sheet 13 is arranged on the upper part of the through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com