Blasting method

A consistent, blast-hole technology used in the field of blasting to address issues such as shear strength and unbalanced resistance between hole walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

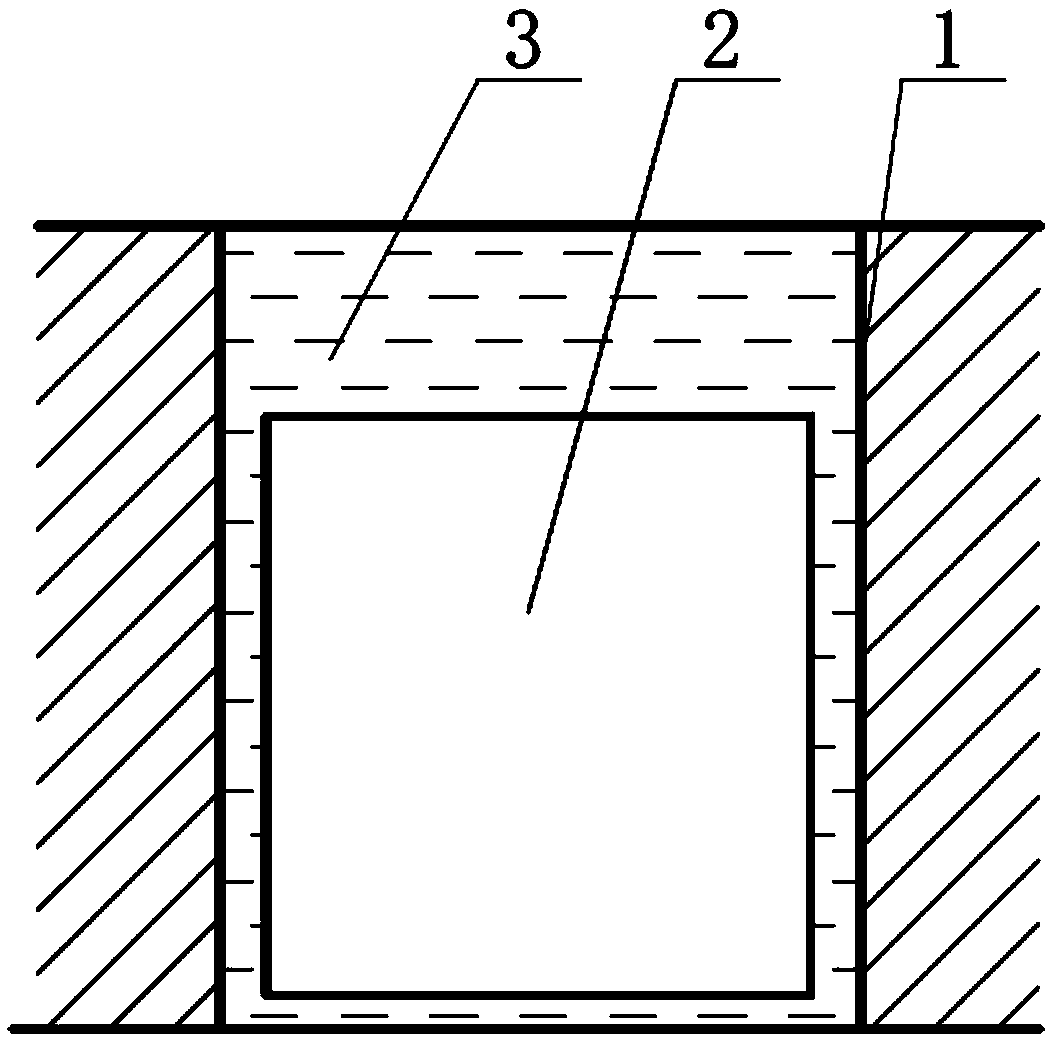

Image

Examples

Embodiment 1

[0068] Water starch is selected for the shear thickening liquid, where the volume ratio of starch to water is 1.5:1; the blasting concentrator uses ordinary TNT explosive packs; the blasting holes are digged at the position to be blasted; the starch is added to the water and mixed evenly After about 5-15 minutes, prepare water starch, pour the water starch into the blast hole; place the ordinary TNT explosive bag in the blast hole, and push the ordinary TNT explosive bag into the water starch; The water starch completely seals the blasting blast hole, so as to completely fill the blasting concentrator in the blasting blast hole; the water starch on the side close to the outlet of the blasting blast hole is filled with 10cm gun mud; A cardboard is arranged between the mud and the water starch; the ordinary TNT explosive pack is detonated.

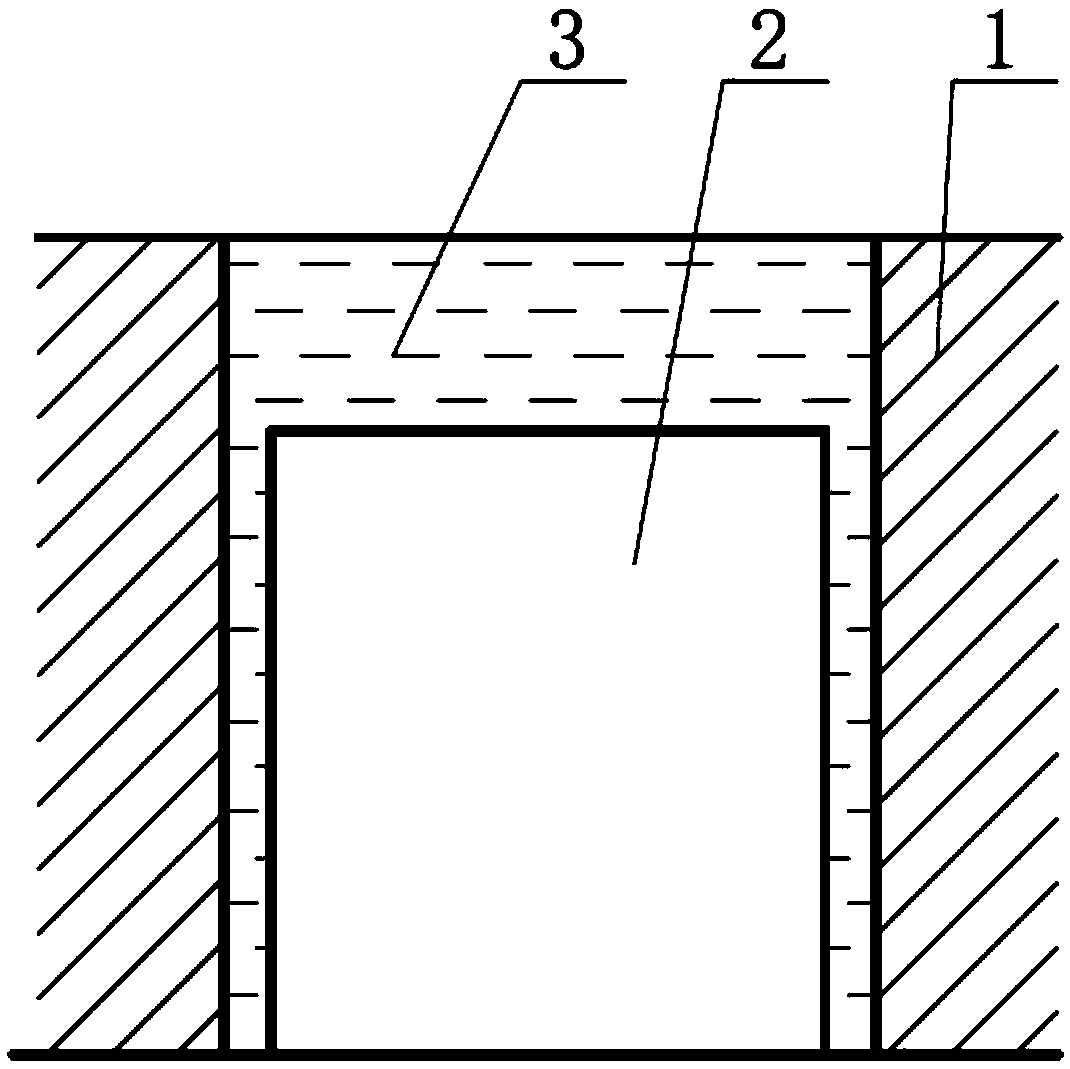

Embodiment 2

[0070] The shear thickening liquid uses water starch, where the volume ratio of starch to water is 2:1; the blasting concentrator uses ordinary TNT explosive packs; the blasting holes are digged at the position to be blasted; the starch is added to the water and mixed evenly After about 5-15 minutes, prepare water starch, pour the water starch into the blast hole, place the ordinary TNT explosive bag in the blast hole, and push the ordinary TNT explosive bag into the water starch. The water starch completely closes the blasting hole, so as to completely fill the blasting concentrator in the blasting blast hole; the outer side of the water starch near the exit of the blasting blast hole is filled with 5cm gun mud; A cardboard is arranged between the mud and the water starch; the ordinary TNT explosive pack is detonated.

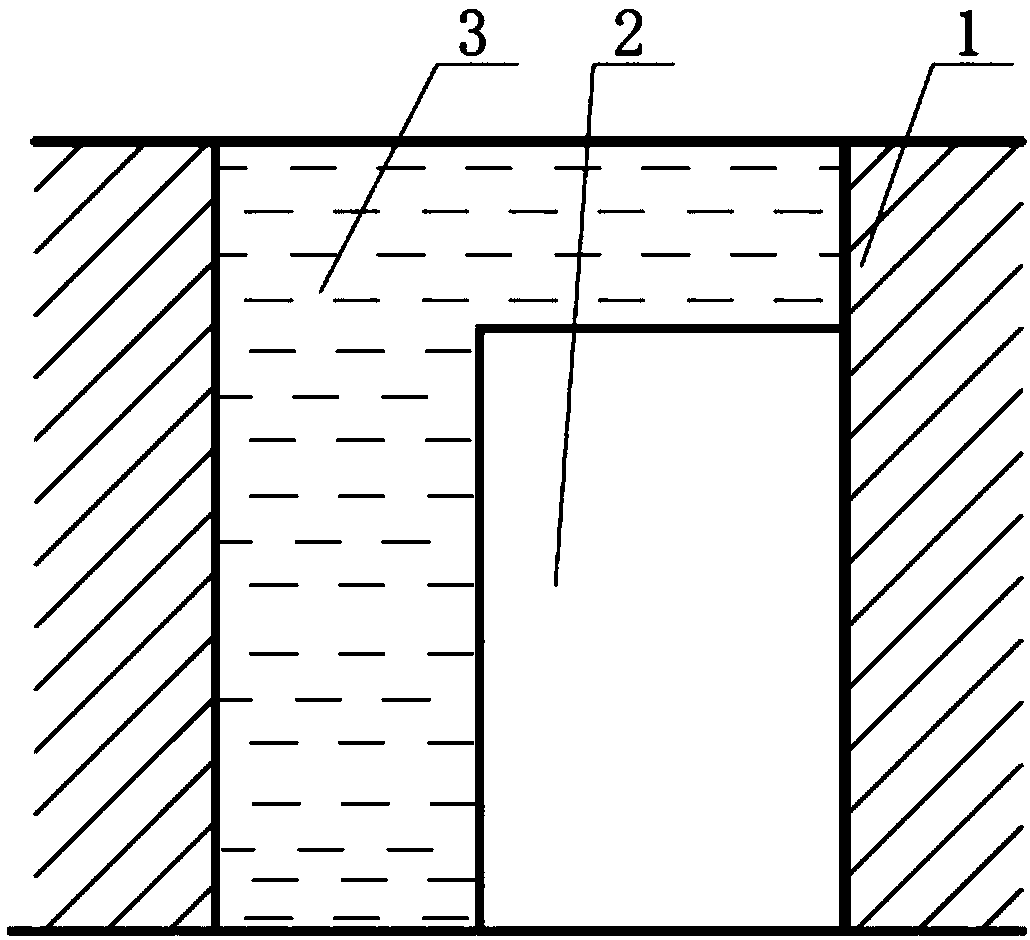

Embodiment 3

[0072] The shear thickening liquid uses water starch, where the volume ratio of starch to water is 2.5:1; the blasting concentrator uses ordinary TNT explosive packs; the blasting holes are digged at the position to be blasted; the starch is added to the water and mixed evenly After about 5-15 minutes, prepare water starch, pour the water starch into the blast hole, place the ordinary TNT explosive bag in the blast hole, and push the ordinary TNT explosive bag into the water starch; The water starch completely closes the blasting hole, so as to completely fill the blasting concentrator in the blasting blast hole; the outer side of the water starch near the exit of the blasting blast hole is filled with 5cm gun mud; A cardboard is arranged between the mud and the water starch; the ordinary TNT explosive pack is detonated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Blockiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com