Oil draining bolt used for electric drive automobile transmission and transmission

A technology of automobile gearbox and oil drain bolt, which is applied in the direction of gearbox, components with teeth, parts of transmission device, etc., can solve the problems of unfavorable gearbox shifting, increase of lubricating oil viscosity, etc., and achieve good shifting performance. , Prevent viscosity increase, good effect of gear lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

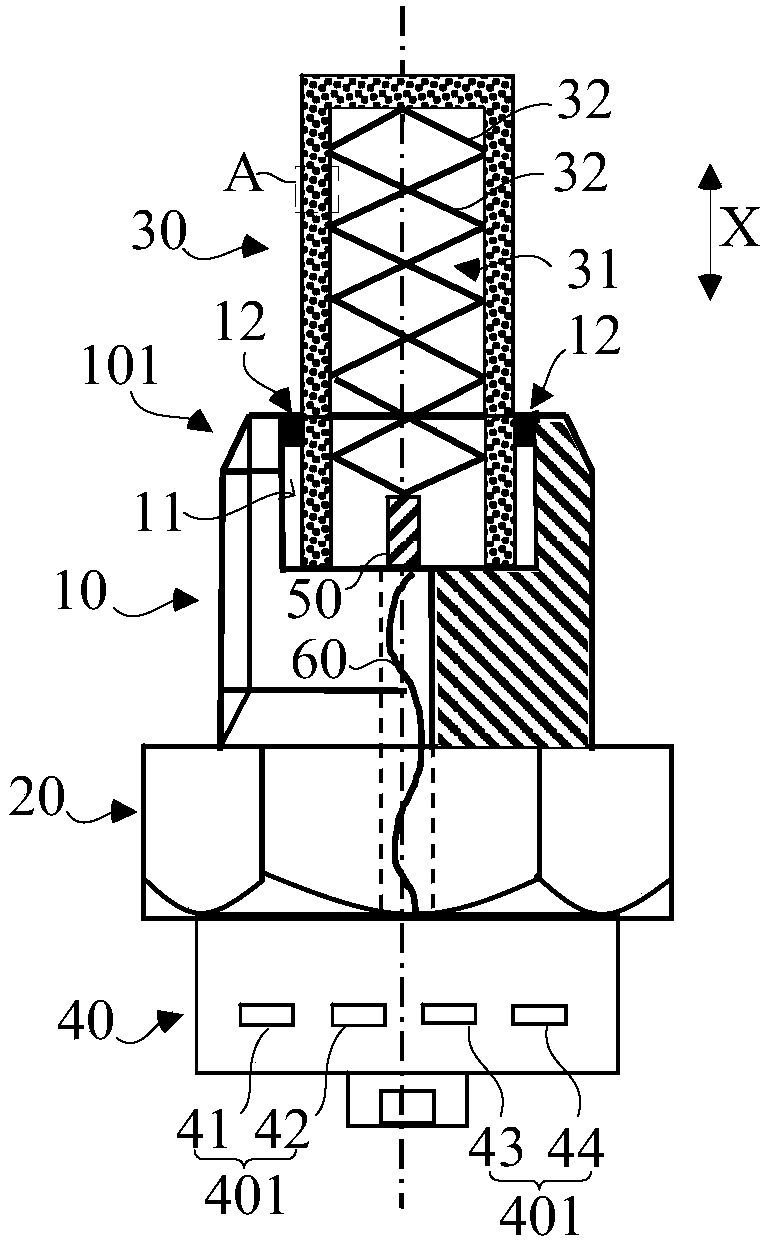

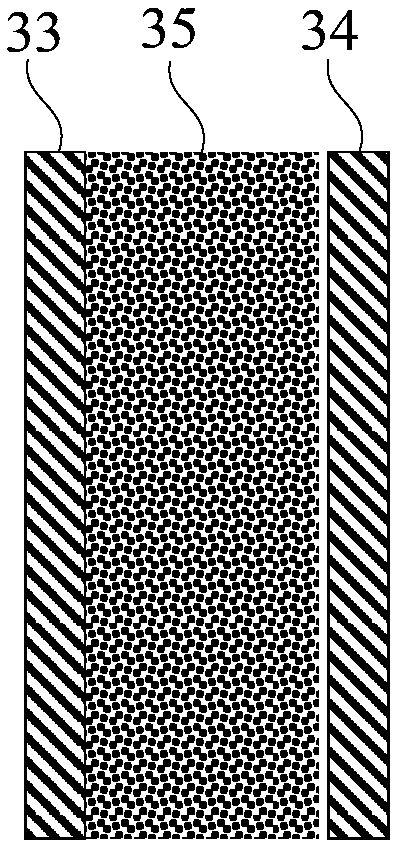

[0023] An embodiment of the present invention provides an oil drain bolt, which is installed at the bottom of the gearbox of an electric drive vehicle. After the oil drain bolt is opened, the lubricating oil in the gearbox of the electric drive vehicle can be released, so as to renew the lubricating oil in the gearbox. refer to figure 1 , the oil drain bolt of this embodiment includes a bolt body 10 and a nut end 20. The bolt body 10 has an insertion end 101 inserted into the gearbox. fixed to the bottom of the gearbox. The insertion end 101 of the bolt body 10 is provided with an electric heating part 30 , and the electric heating part 30 is insulated from the insertion end 101 for heat conduction.

[0024] The insertion end 101 of the oil drain bolt is inserted into the gearbox of the electric drive vehicle. In a cold environment, the low gear of the electric drive vehicle is started by pure electric drive. When the temperature of the lubricating oil in the gearbox of the e...

no. 2 example

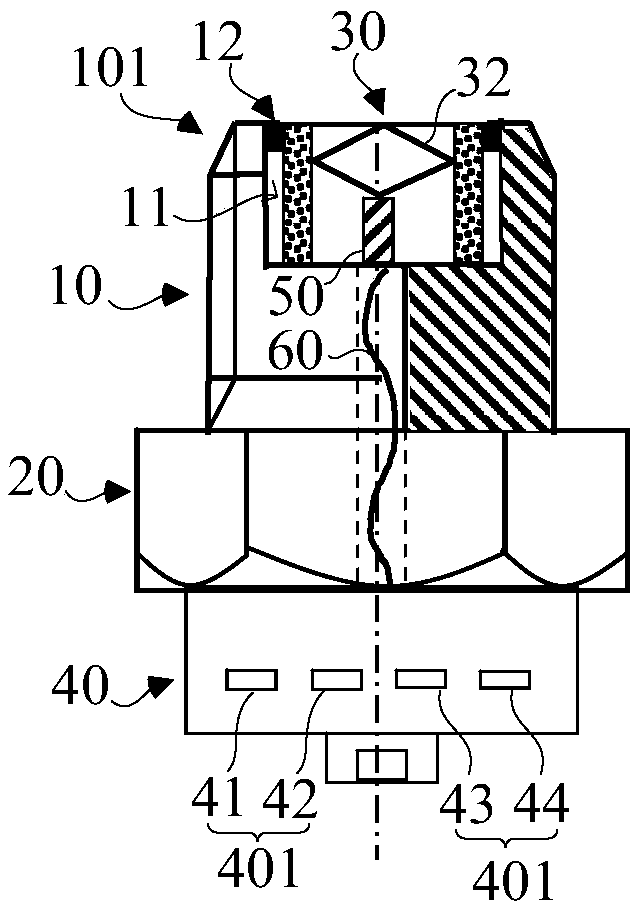

[0040] refer to image 3 The difference between this embodiment and the first embodiment is that the electric heating part 30 is disposed in the slot 11 of the insertion end 101 . That is, the electric heating part 30 is completely placed in the slot 11 and does not protrude from the slot 11 of the insertion end 101 . The rest of the structure is the same as that in the first embodiment, and will not be repeated here.

no. 3 example

[0042] This embodiment provides a gearbox, especially a gearbox used in electric vehicles. The gearbox includes: a box body, and a bolt hole is provided at the bottom of the box body, and the oil drain bolt in the above embodiment is connected with the bolt hole. The gearbox of this embodiment also includes the control unit of the above embodiment. The control unit may be integrated in a transmission control unit (TCU) of the electric drive vehicle, or the control unit may be connected to the TCU of the transmission control unit of the electric drive vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com