Oil distribution valve

A technology of oil distribution valve and valve hole, which is applied in the field of hydraulic valves, can solve the problems of large leakage, time-consuming, and high maintenance costs, and achieve the effects of reducing maintenance costs, reducing convenience, and compact volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

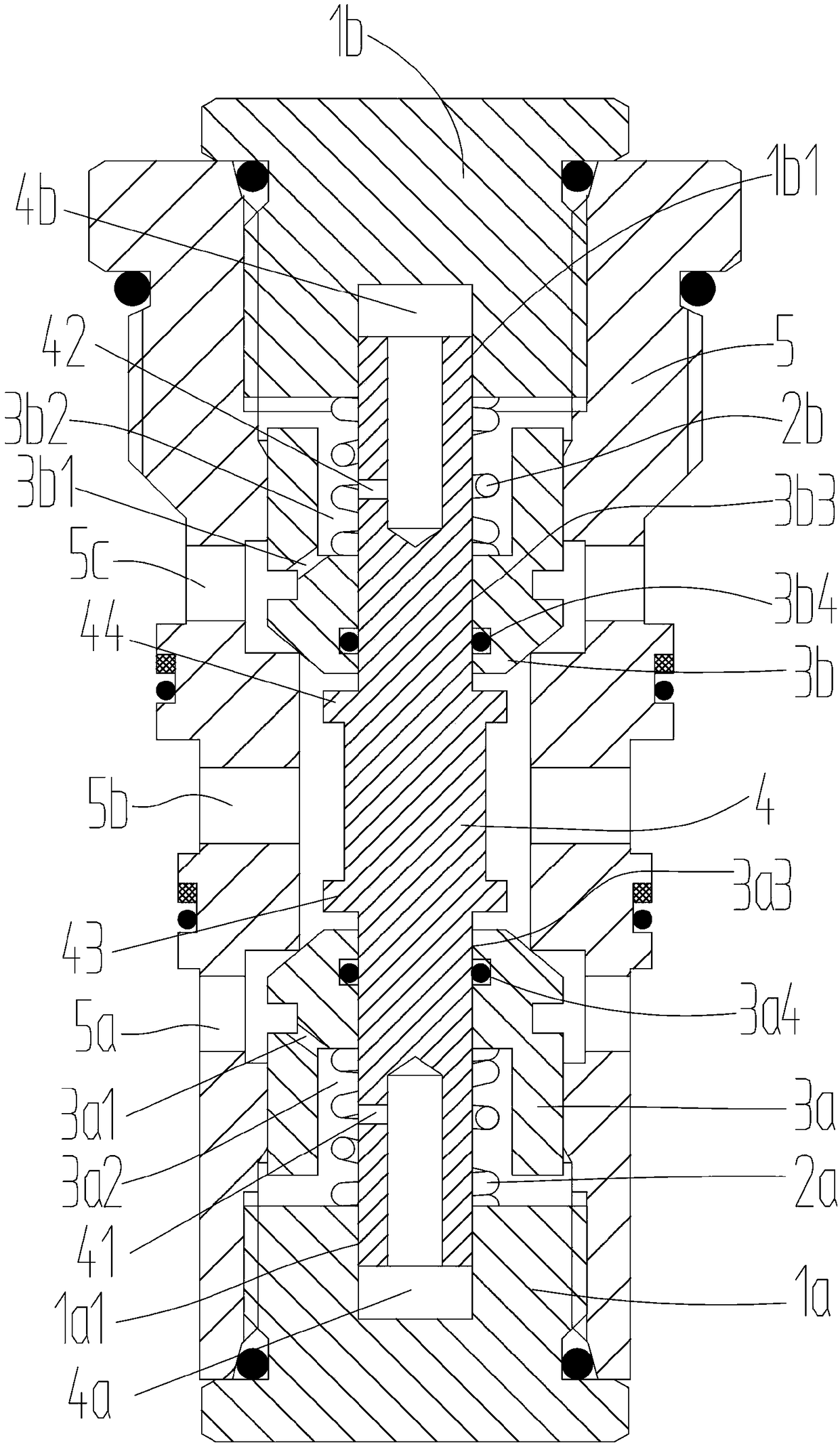

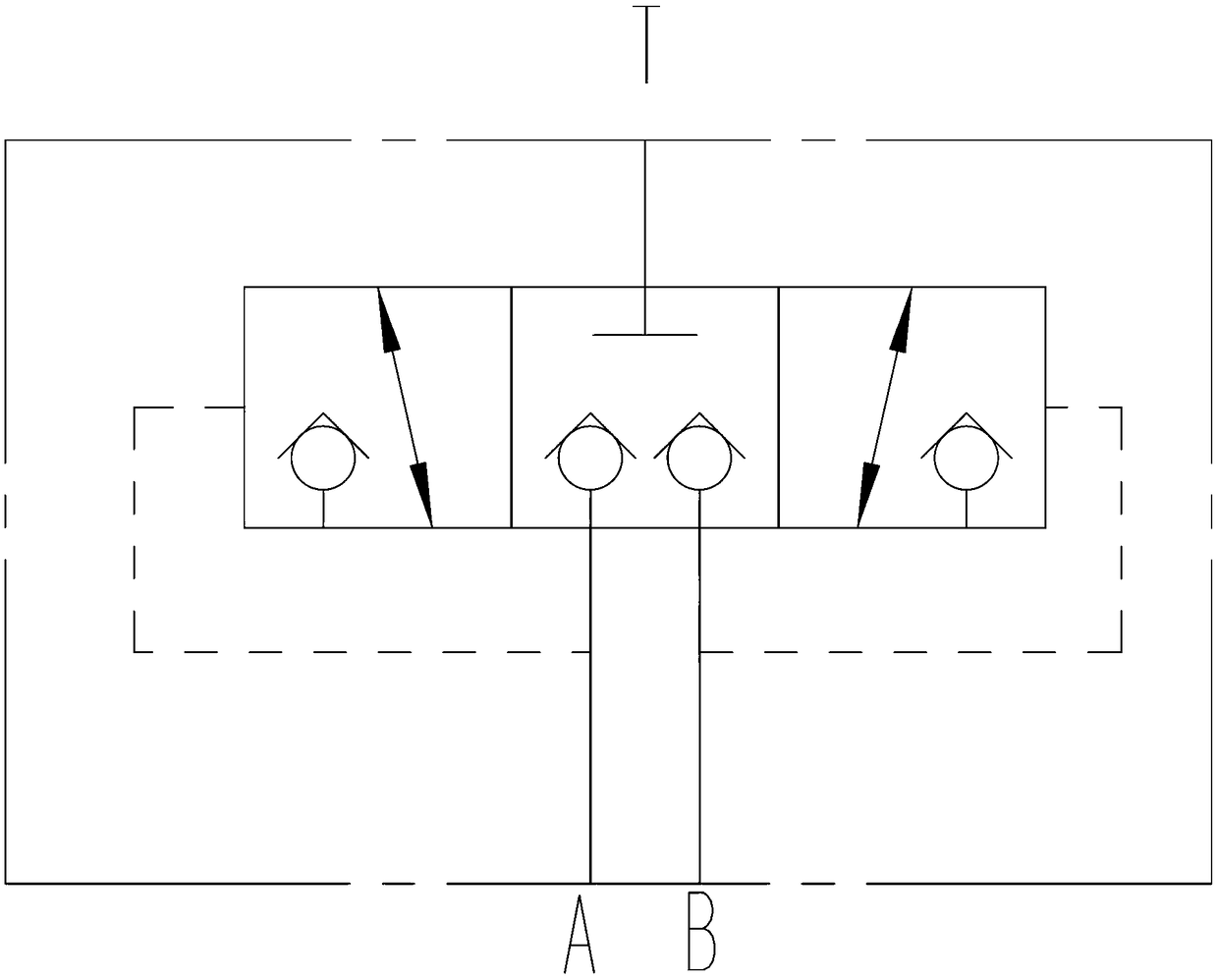

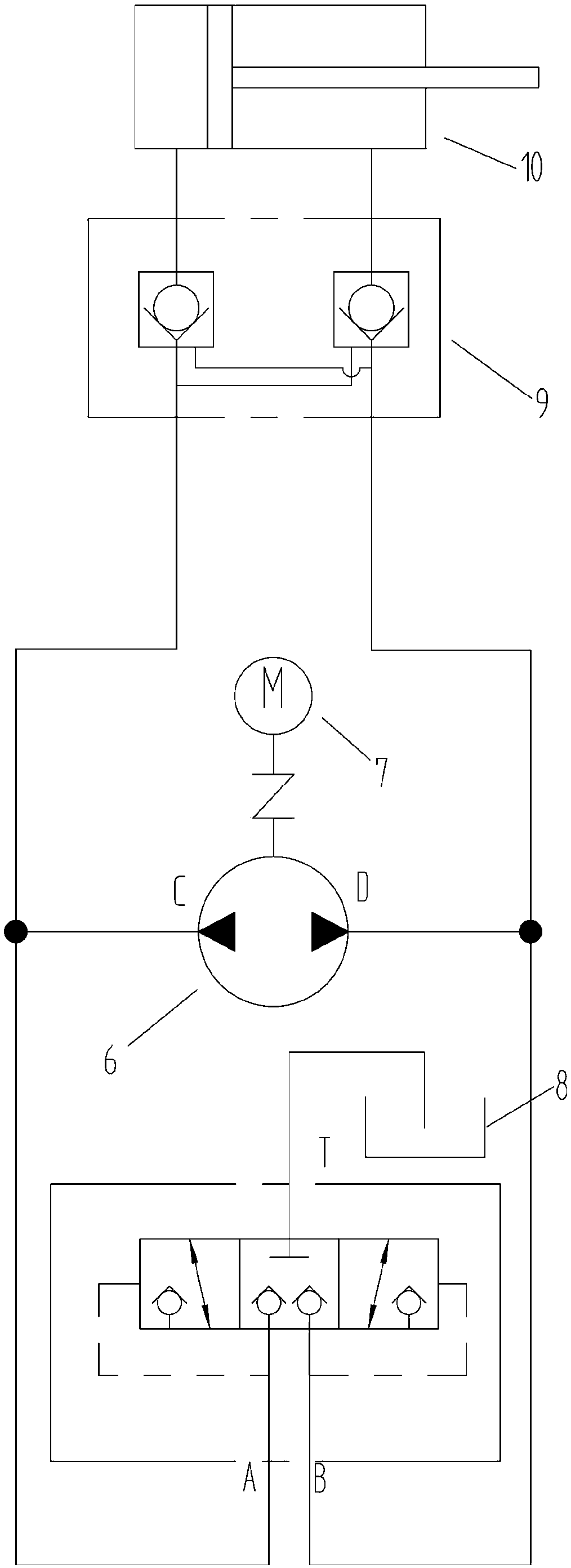

[0019] see Figure 1-5 As shown, the present invention provides an oil distribution valve, which includes a valve sleeve 5 and a control rod 4. A first threaded hole 501 and a first valve hole 502 communicating with each other are arranged coaxially in the valve sleeve 5 in sequence from bottom to top. , a communication hole 503 , a second valve hole 504 , and a second threaded hole 505 . A port 5a communicating with the first valve hole 502 , a port T 5b communicating with the communicating hole 503 , and a port communicating with the second valve hole 504 are provided on the circumferential side of the valve sleeve 5 . B port 5c. The first valve hole 502 is slidably connected with the first taper spool 3a for controlling the on-off of the T oil port 5b and the A oil port 5a, and the second valve hole 504 is slidably connected with the T oil port 5b and the A oil port 5a. The B oil port 5c connects and disconnects the second poppet spool 3b. The valve sleeve 5 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com