Scroll compressor

一种涡旋压缩机、压缩机构的技术,应用在涡旋压缩机领域,能够解决刀具切削断续、卷板间隙扩大、涡旋压缩机性能降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

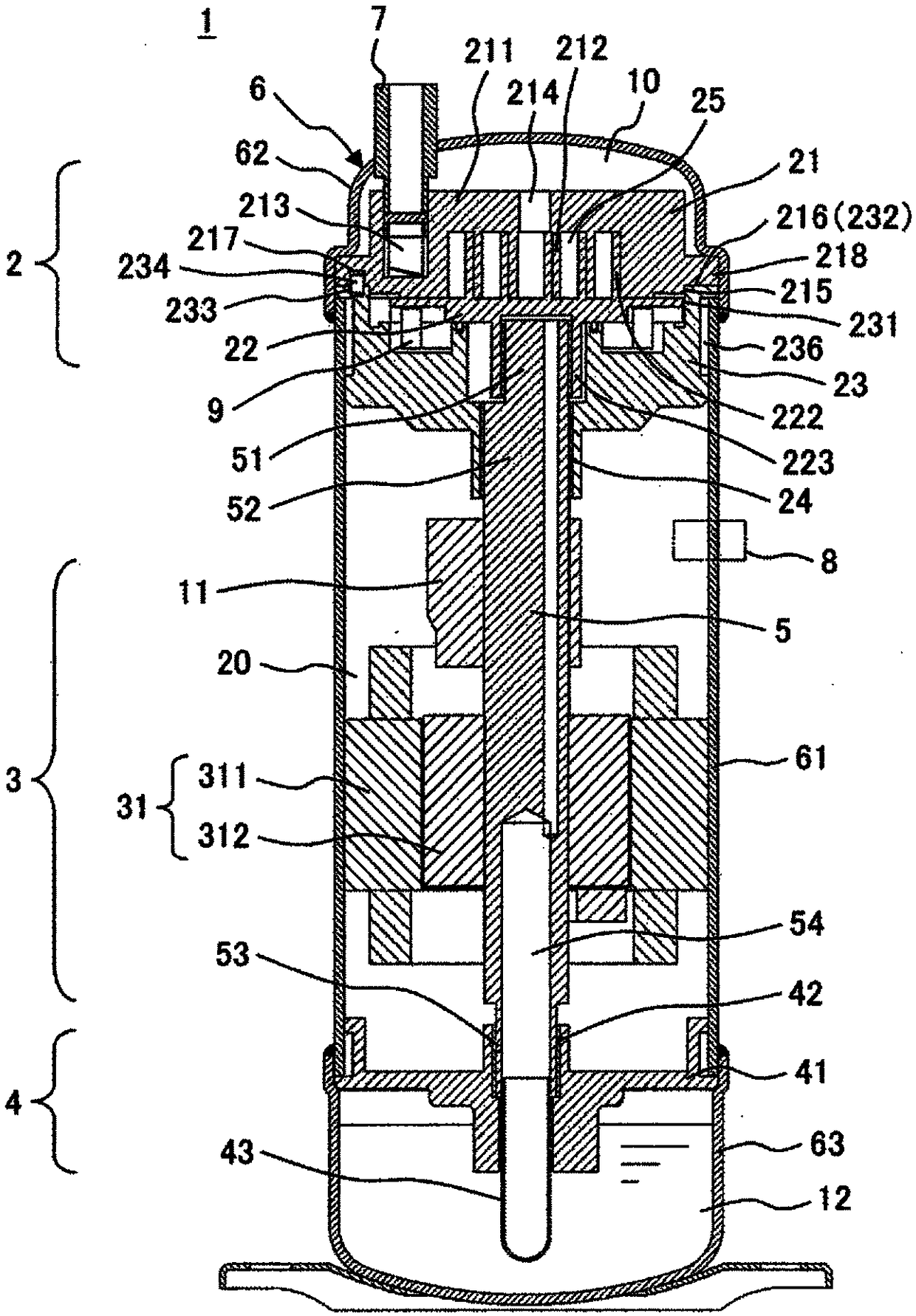

[0030] use Figure 1 to Figure 6 , Embodiment 1 of the scroll compressor of the present invention will be described.

[0031] First, use figure 1 The overall configuration of the scroll compressor of the first embodiment will be described. figure 1 It is a longitudinal cross-sectional view showing the overall configuration of the scroll compressor of the first embodiment.

[0032] The scroll compressor 1 is configured to house a compression mechanism unit 2 , a drive unit 3 , an oil supply mechanism unit 4 , a rotating shaft 5 , and the like in a closed container 6 . In this example, from figure 1 From the upper part shown, the compression mechanism part 2, the drive part 3, and the oil supply mechanism part 4 are arranged in the above-mentioned closed container 6 in order, and the above-mentioned compression mechanism part 2, the above-mentioned drive part 3 and the above-mentioned oil supply mechanism part 4 The connection is made via the rotating shaft 5 .

[0033] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com