Water flow direction fixing pipeline hydroelectric module and system and power generation method

A technology of water flow direction and power generation system, applied in the field of fluid dynamics, can solve the problems of high cost and high cost of installed capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

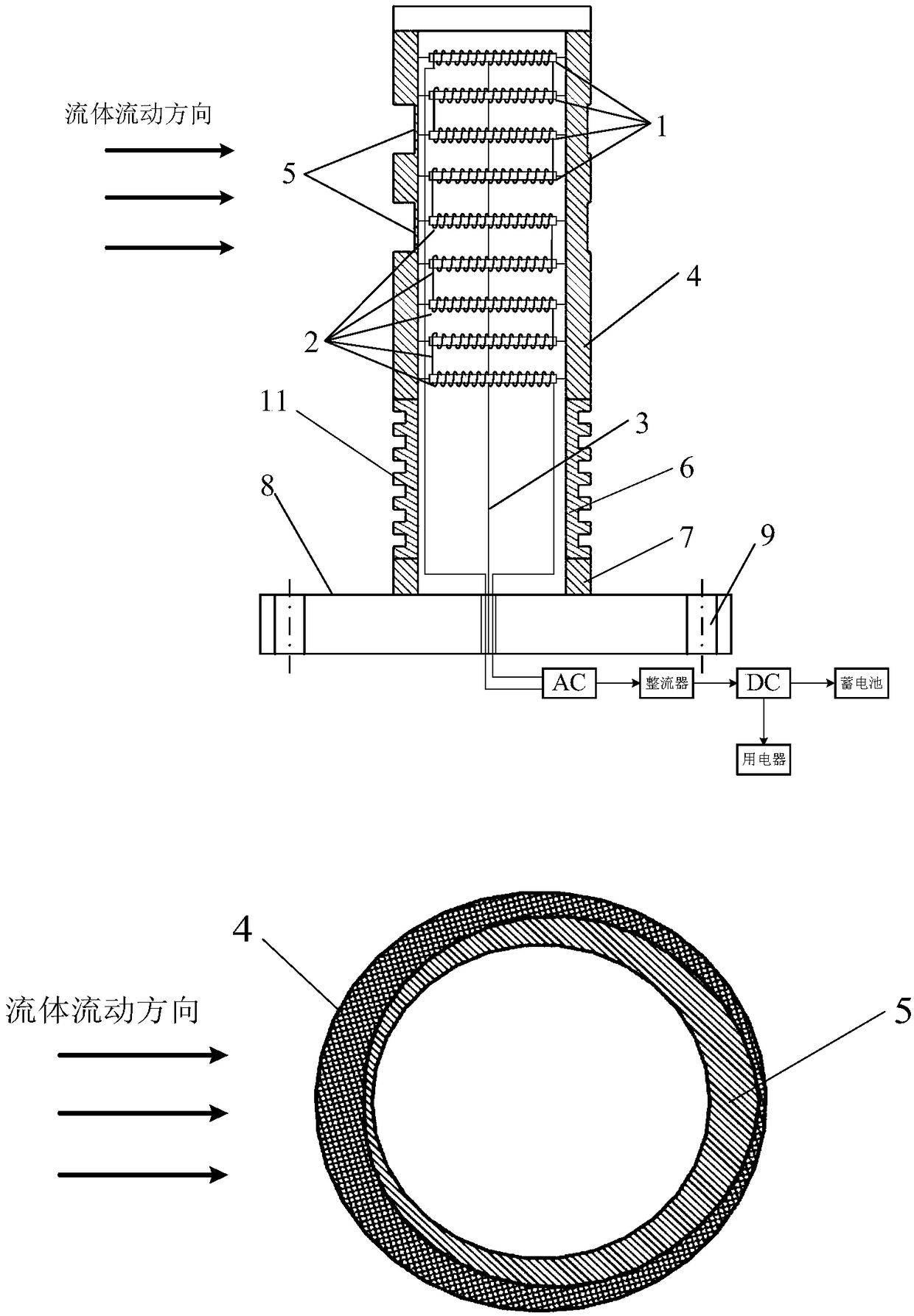

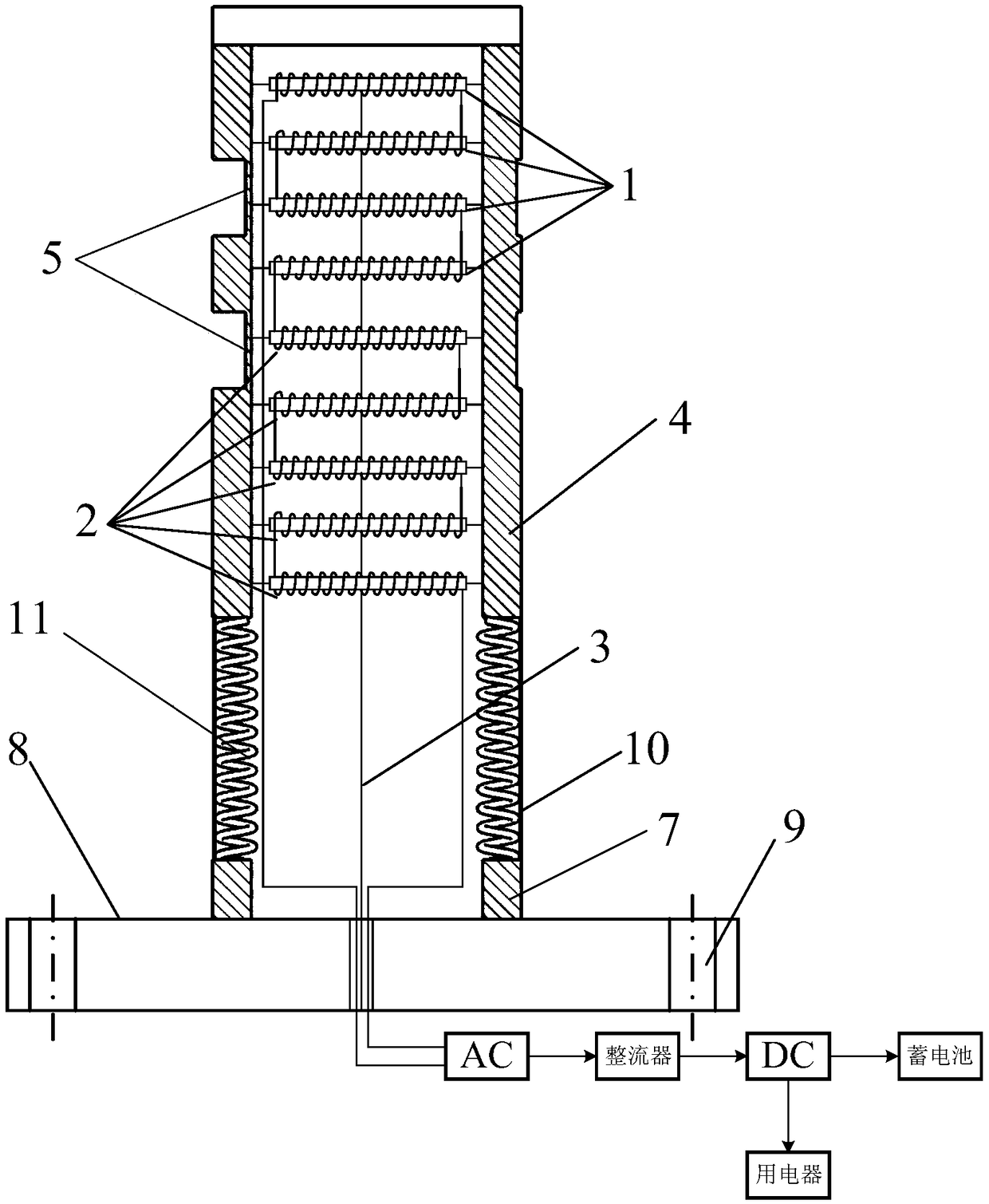

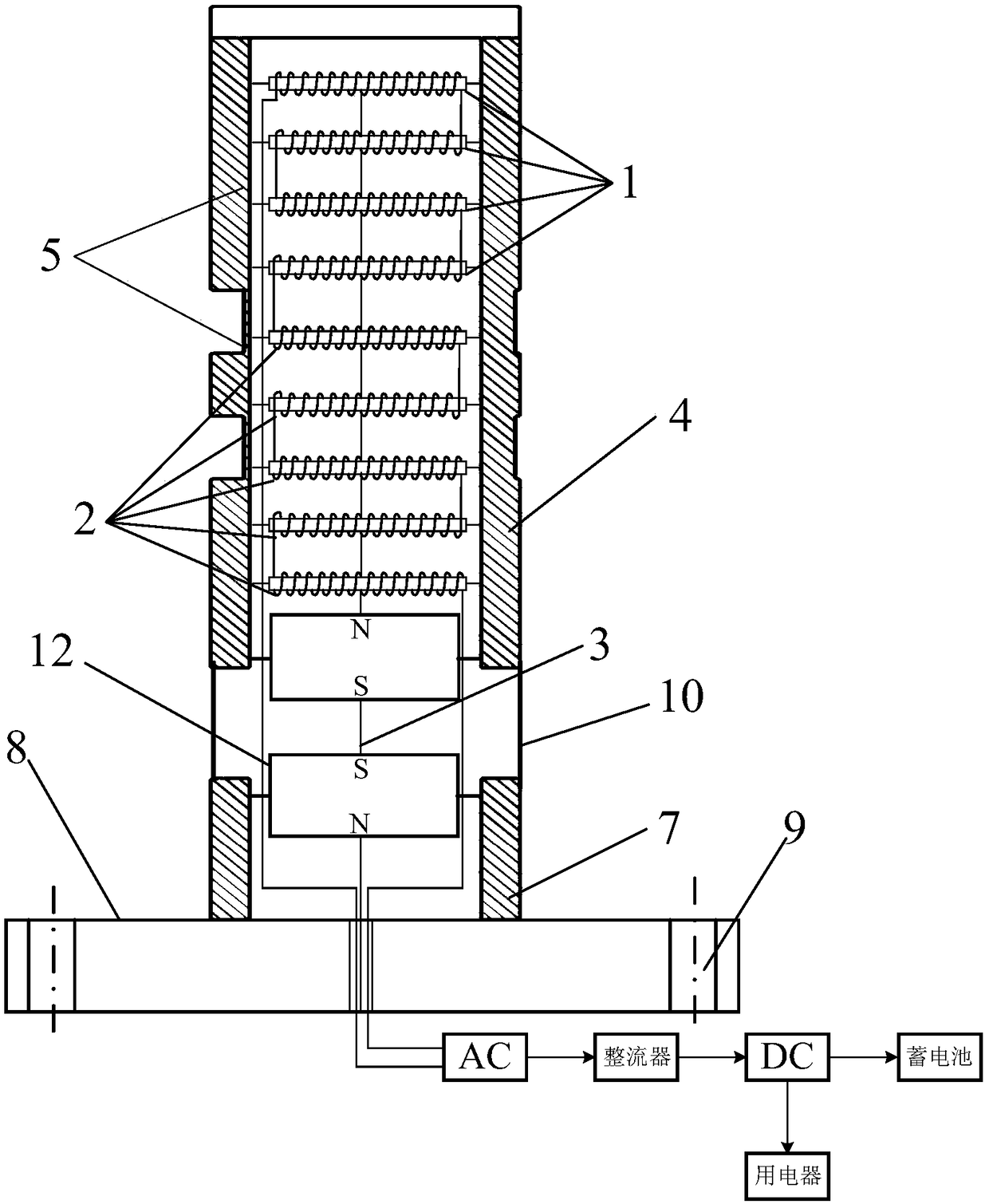

[0027] Combine below Figure 1~5 A pipeline hydroelectric power generation module with fixed water flow direction and the operation process of the system are described in detail.

[0028] The pipeline hydropower module or a system composed of multiple power generation modules is installed in the pipeline through the installation hole of the fixed base, and the distance between the top and the opposite pipe wall is greater than 10mm so as to be far away from the low energy flow area of the opposite pipe wall.

[0029] As the water flows through the obstacle, the swinging pipe forms a vortex behind the obstacle, and the disturbance of the vortex causes it to swing left and right with the semi-flexible support at the lower part;

[0030] With the swing of the swing tube, the first group of power generation elements fixed on its inner wall also swing left and right, and the second group of power generation elements are fixed on the fixed base through the fixed rod and are not mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com