Steam cleaner

A technology for cleaners and steam generators, applied in the field of steam cleaners, can solve problems such as the difficulty of assembling the casing, and achieve the effects of improving heat insulation, simplifying assembly, and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

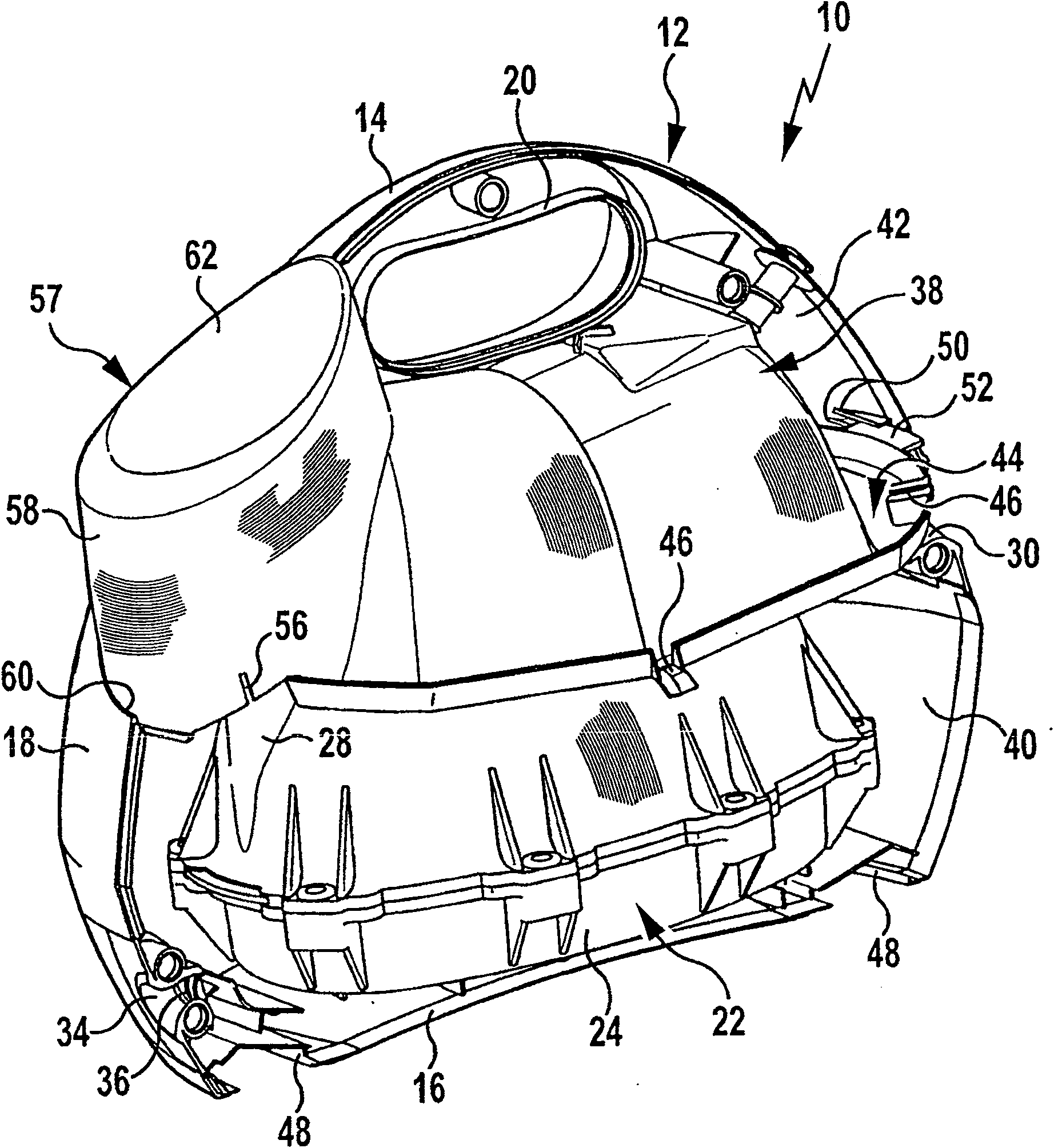

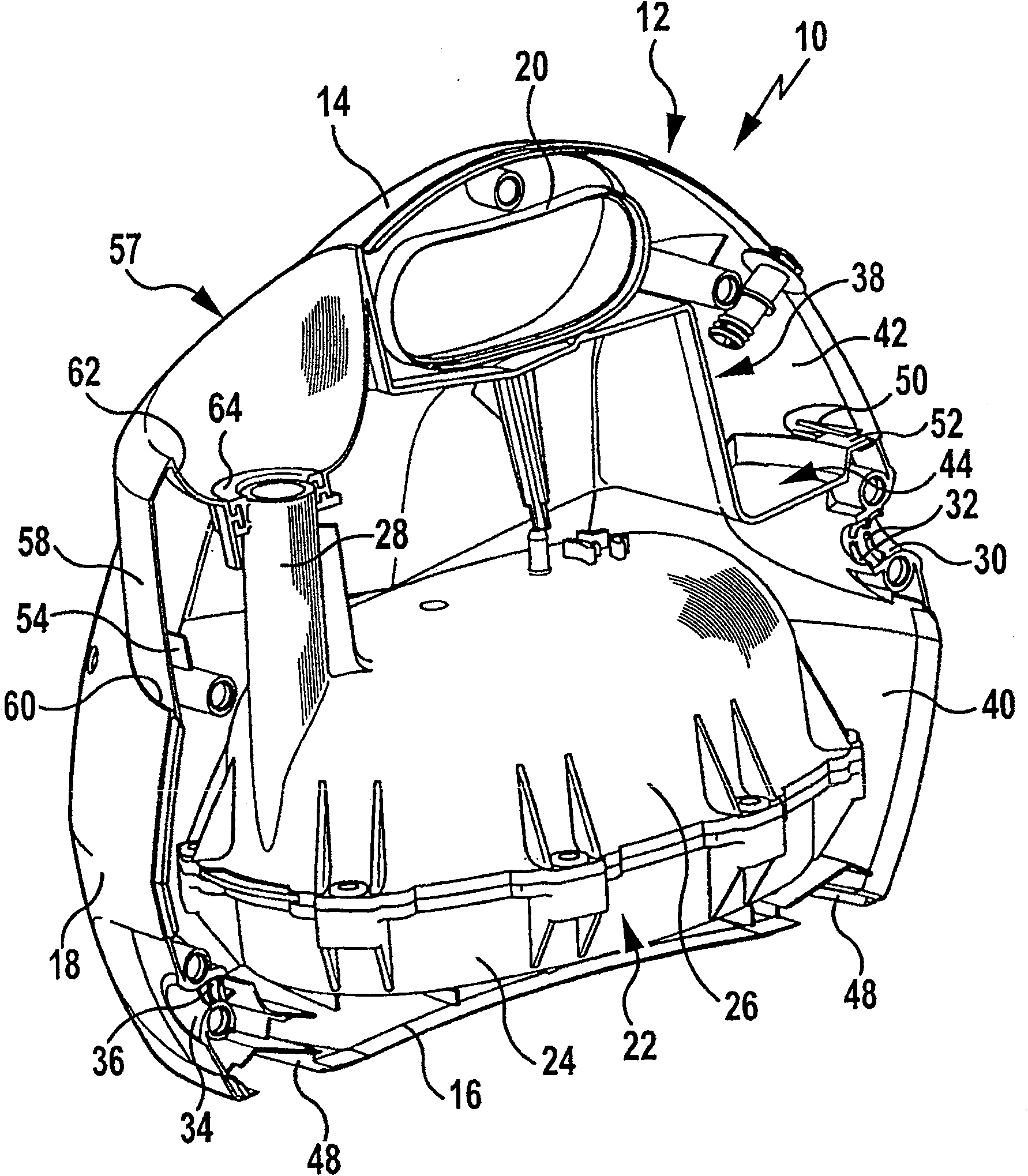

[0022] In the drawing there is shown a steam cleaner generally designated by the reference numeral 10, which has a housing 12 which consists of two housing halves which can be assembled together, only one housing being shown in the drawing Half-shell 14, on which a correspondingly designed housing half-shell can be placed. The two housing half-shells respectively form half of a bottom wall 16, on which a convexly curved side wall 18 is integrally connected, and a handle 20 is formed in its upper area facing away from the bottom wall 16, so that the user can follow the The steam cleaner 10 is shipped in a canister.

[0023] The housing 12 accommodates a steam generator with an electrically heatable steam boiler 22 . The steam boiler is designed in two parts and comprises a lower part 24 and an upper part 26 which are screwed together in a liquid-tight manner. Molded onto the upper part 26 is a filling socket 28 , the free end of which can be closed by a known and therefore no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com