A multifunctional oil-gas separator

A kind of oil-gas separator, multi-functional technology, applied in the direction of fuel air filter, machine/engine, fuel air inlet, etc., can solve the problems of inconvenient space layout of diesel engine, single function and complex structure of oil-gas separator, etc., to achieve The effect is excellent, the economy is improved, and the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described with reference to the drawings and specific embodiments.

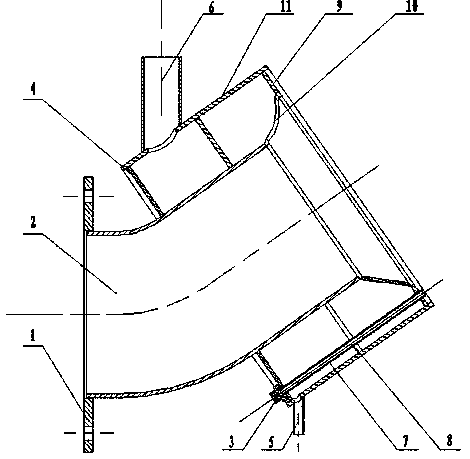

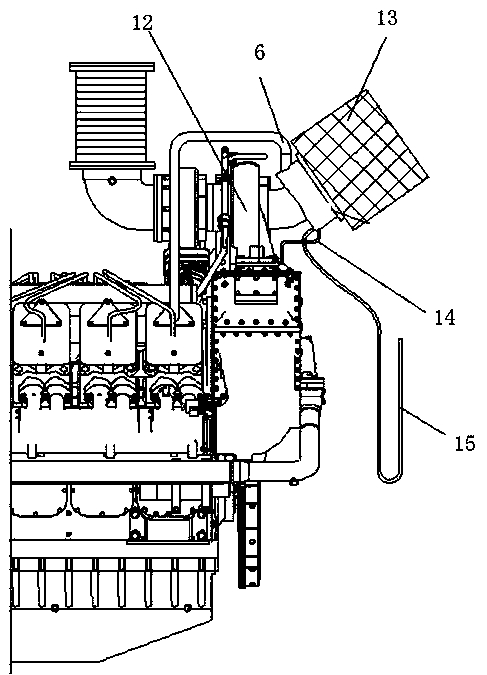

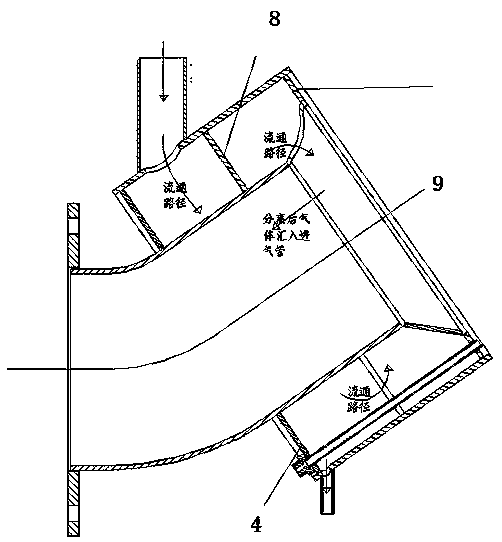

[0023] Such as figure 1 As shown, a multi-functional oil-gas separator, the multi-functional oil-gas separator has an inlet pipe 2 communicating with a supercharger 12; the front end of the inlet pipe 2, that is, the outlet end, is connected to the The supercharger 12 is connected; The rear end of the air inlet pipe 2, that is, the inlet end, is provided with a tapered pipe 10; the tapered pipe 10 is a structure that gradually expands in diameter from the inlet end of the air inlet pipe; the described The outside of the intake pipe 2 and the tapered pipe 10 are sleeved with an outer sleeve 11 concentrically arranged therewith; the outer sleeve 11 is a cylindrical structure with front and rear openings; the front opening of the outer sleeve 11 is sleeved in the inlet The front partition 4 on the trachea 2 and the tapered pipe 10 is sealed; the rear opening of the outer casing i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com