Piling-machine chain drill bit high in controllability

A chain and machine-chain technology, which is applied to drilling tools, sheet pile walls, drilling equipment, etc., can solve problems such as block phenomenon, high driving power, and easy failure, so as to reduce the effective area and improve the excavation efficiency , Improve the effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

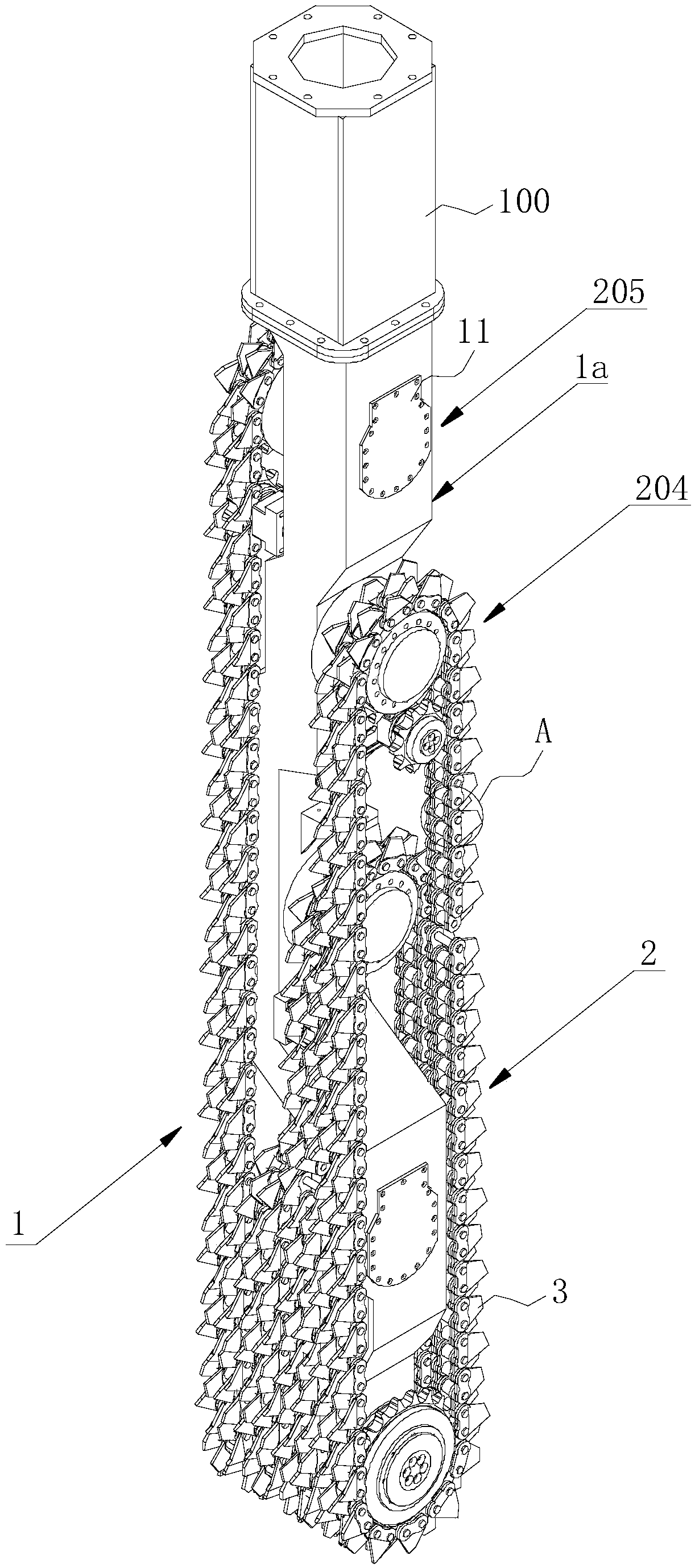

Embodiment 1

[0117] Such as Figure 17 As shown, a chain drill bit with sufficient soil stirring includes a cutting carrier 101 located at the lower part of the drill rod that can rotate along the circumferential direction and is connected end to end (obviously, the cutting carrier 101 is a more specific form of the chain carrier , when the chain carrier is ring-shaped and the working mode is circumferential rotation, the chain carrier is the above-mentioned cutting carrier 101; this will not be described in detail below), the surface of the cutting carrier 101 has a raised structure 2, The cutting carrier 101 includes an endless chain 1 connected with a power mechanism. The power mechanism connected to the endless chain 1 is located at the lower part of the drill pipe to form a power down position. The surface of the endless chain 1 has a raised structure 2 . Preferably, when the endless chain 1 is connected with the drill pipe 100, the endless chain 1 is arranged vertically, that is, whe...

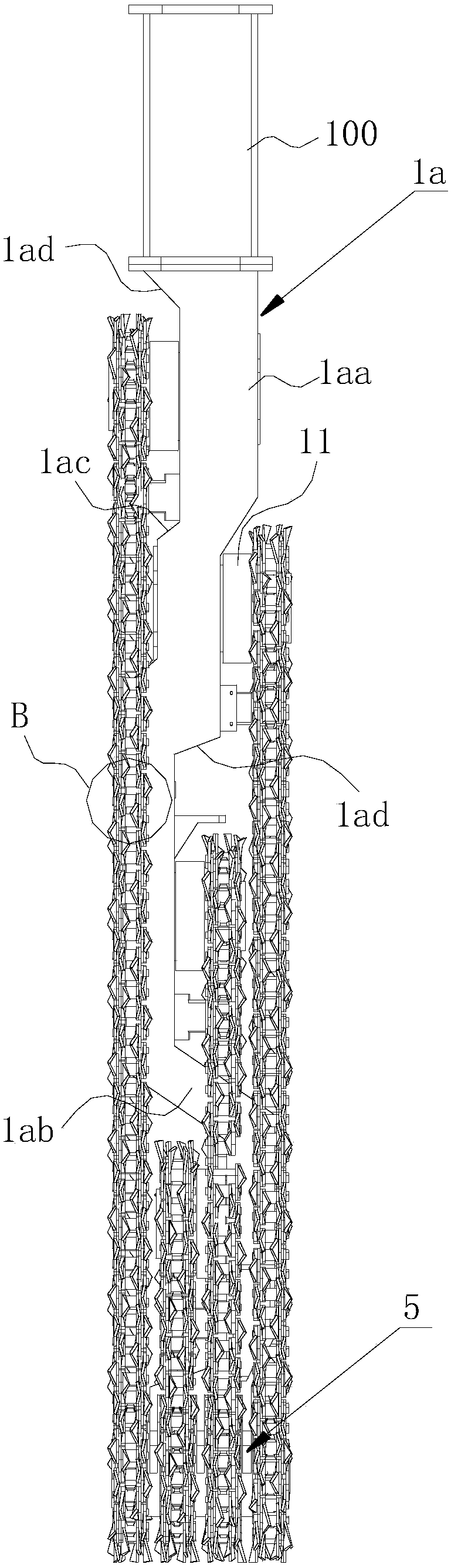

Embodiment 2

[0144] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in combination Figure 20 and Figure 21 As shown, there are two endless chains 1 and they are parallel to each other, and the two endless chains 1 are not on the same plane, that is, there is a gap between the two endless chains 1, and the two endless chains 1 ends are provided with a Auxiliary cutting assembly 4 that rotates. Apparently, under the guidance of this solution, those skilled in the art can design a solution for combining three, four or more endless chains 1 . The auxiliary cutting assembly 4 of this embodiment is basically the same as that of the first embodiment, and the auxiliary chain 9 is arranged laterally, matching the width of the endless chain 1 .

[0145] In the present embodiment, the endless chain 1 is rectangular, and each corner is provided with a sprocket, one or two of which are driving sprockets 1b, and the other ...

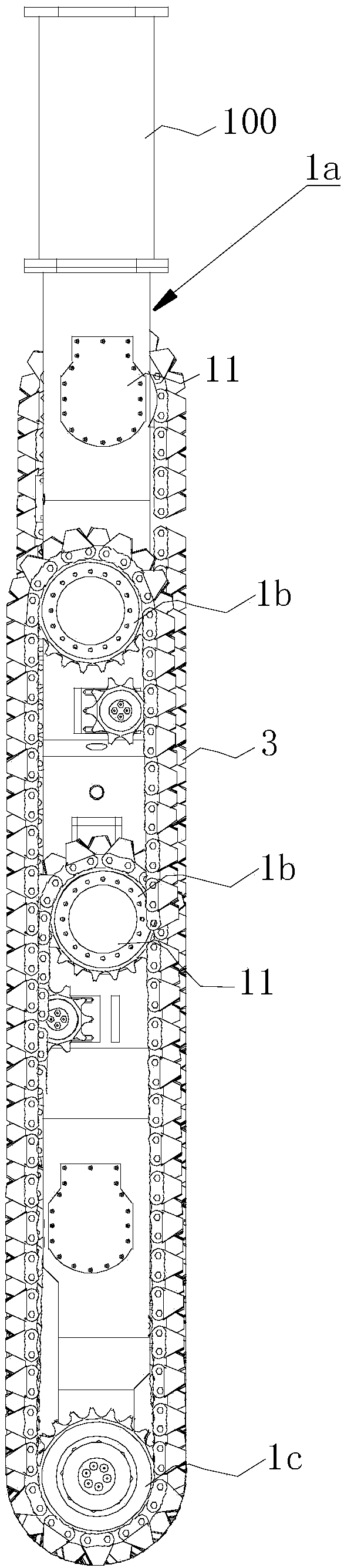

Embodiment 3

[0149] The structure and working process of this embodiment and embodiment 2 are basically the same, the difference is that, as Figure 22 and Figure 23 As shown, the driving mechanism 11 in this embodiment is arranged in the gap between the two endless chains 1, and the output end of the driving mechanism 11 is directly connected to the driving sprocket 1b on the endless connecting body. The drill rod 100 is directly connected to the driving mechanism 11 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pile length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com