Bolted steel bolt prefabricated concrete beam-column mid-side node

A prefabricated concrete and prefabricated assembly technology, which is applied to building components, earthquake resistance, building types, etc., can solve the problems that affect the efficiency of prefabricated beams and columns hoisting, affect the connection efficiency and performance, and the welding quality is difficult to guarantee, so as to ensure the structural performance , High installation efficiency and good deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

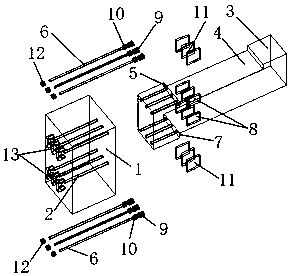

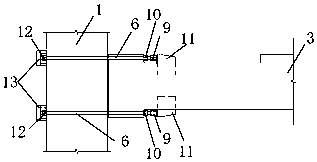

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as Figure 1-2 As shown: the prefabricated concrete column 1 reserves a reinforcement hole 2 in the node area.

[0024] The upper part of the two ends of the prefabricated concrete beam 3 reserves an empty groove 4 at a certain distance from the end section, so that the upper part of the prefabricated beam end forms a sinking step 5, and the length of the empty groove 4 is slightly longer than the length of the connecting steel bar 6 and The distance difference between the hollow groove 4 and the cross-section of the beam end.

[0025] Protruding steps 7 are provided at the lower parts of both ends of the prefabricated beam 3 , and reserved reinforcement holes 2 are provided on the sunken steps 5 and the protruding steps 7 .

[0026] A latch plate slot 8 is reserved at the rear of the sunken step 5 and the protruding step 7 .

[0027] Both ends of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com