Non-ironing treatment method for chemical fiber fabric

A treatment method and fabric technology, which is applied in the treatment of textile materials, fiber treatment, spray/jet textile material treatment, etc., can solve the problems of troublesome, wrinkled chemical fiber fabrics, etc., to increase air permeability, protect the properties of chemical fiber fabrics, and cover Comprehensive and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

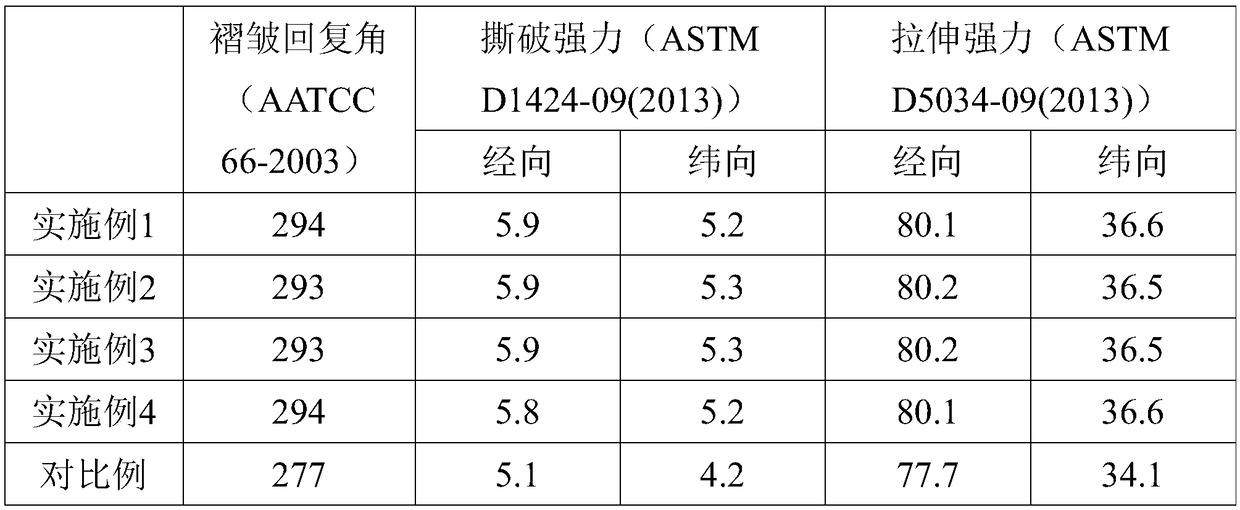

Examples

Embodiment 1

[0027] A non-ironing treatment method for chemical fiber fabrics, comprising the following steps:

[0028] (1) Immerse the chemical fiber fabric in 50°C water for 20 minutes, then quickly put it in 4°C cold water to cool, hang it to dry after cooling until there is no water dripping;

[0029] (2) spread the chemical fiber fabric after step (1) on the flat work surface, flatten it with a flat plate, and then hang it up;

[0030] (3) Add the non-ironing treatment agent to 30-40 times of water and mix evenly, atomize and spray on the erected chemical fiber fabric with an atomizer, and the consumption of the non-ironing treatment agent is 15% of the weight of the chemical fiber fabric;

[0031] (4) Bake the chemical fiber fabric sprayed with the non-ironing treatment agent at 120° C. for 10 minutes with a baking machine;

[0032] (5) Put the baked pure cotton products into steam at 130°C and 0.27Mpa saturated vapor pressure for 40 minutes, spread them on a flat work surface after...

Embodiment 2

[0035] A non-ironing treatment method for chemical fiber fabrics, comprising the following steps:

[0036] (1) Immerse the chemical fiber fabric in 70°C water for 30 minutes, quickly put it in 6°C cold water to cool, hang it to dry after cooling until there is no water dripping;

[0037] (2) spread the chemical fiber fabric after step (1) on the flat work surface, flatten it with a flat plate, and then hang it up;

[0038] (3) Add the non-ironing treatment agent to 40 times of water and mix evenly, atomize and spray on the erected chemical fiber fabric with an atomizer, and the consumption of the non-ironing treatment agent is 30% of the weight of the chemical fiber fabric;

[0039] (4) Bake the chemical fiber fabric sprayed with the non-ironing treatment agent at 150° C. for 12 minutes with a baking machine;

[0040] (5) Put the baked pure cotton products into steam at 130°C and 0.27Mpa saturated vapor pressure for 60 minutes, spread them on a flat work surface after cooling...

Embodiment 3

[0046] A non-ironing treatment method for chemical fiber fabrics, comprising the following steps:

[0047] (1) Immerse the chemical fiber fabric in water at 60°C for 25 minutes, then quickly put it in cold water at 5°C to cool, and hang it to dry after cooling until there is no water dripping;

[0048] (2) spread the chemical fiber fabric after step (1) on the flat work surface, flatten it with a flat plate, and then hang it up;

[0049](3) Add the non-ironing treatment agent to 35 times of water and mix evenly, atomize and spray on the erected chemical fiber fabric with an atomizer, and the consumption of the non-ironing treatment agent is 20% of the weight of the chemical fiber fabric;

[0050] (4) Bake the chemical fiber fabric sprayed with the non-ironing treatment agent at 130° C. for 11 minutes with a baking machine;

[0051] (5) Put the baked pure cotton products into steam at 130°C and 0.27Mpa saturated vapor pressure for 50 minutes, spread them on a flat work surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com