Water inlet valve and washing machine

A technology for water inlet valves and washing machines, which is applied in the field of solenoid valves and can solve problems such as large impact, impact, and overall water intake exceeding the required range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

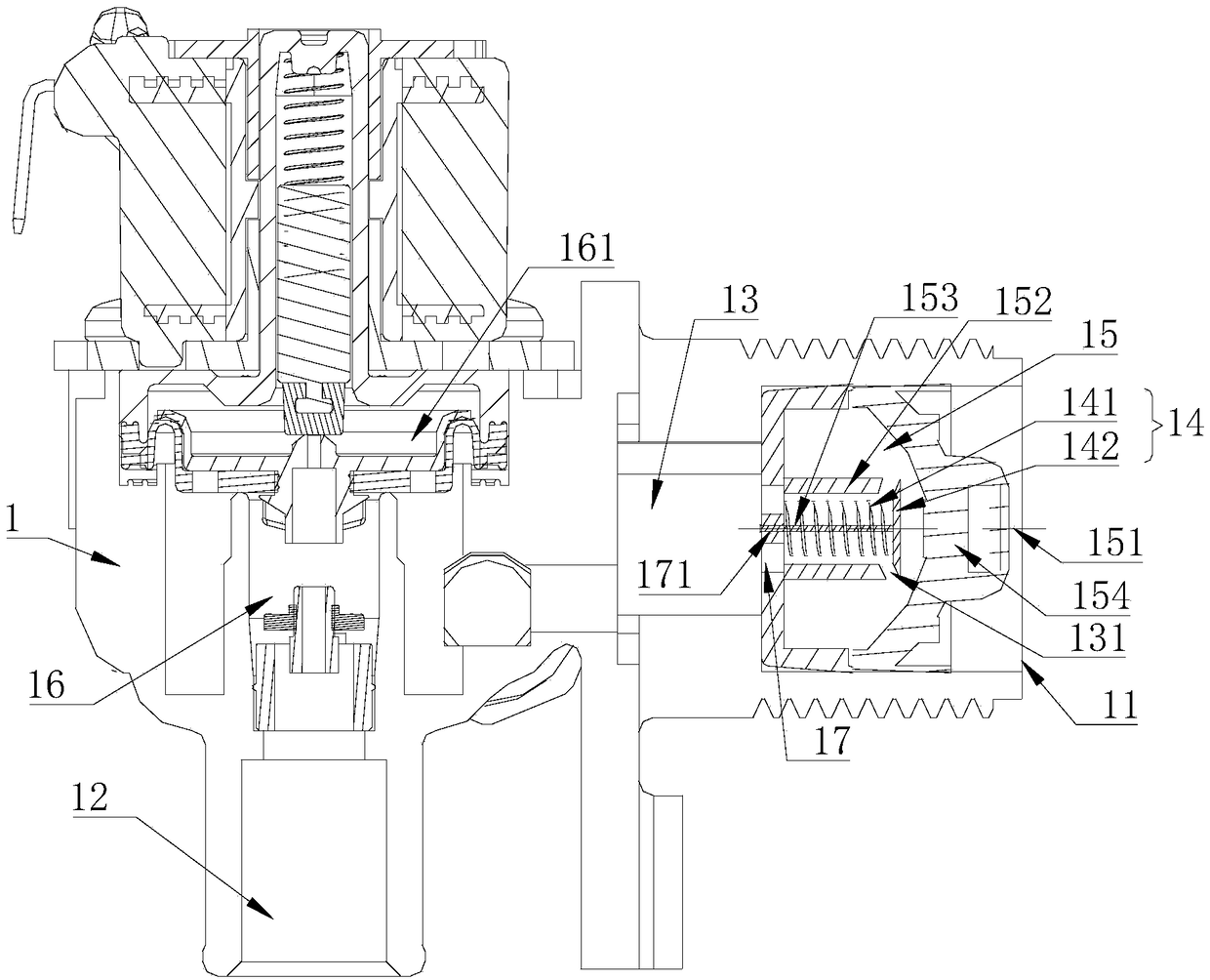

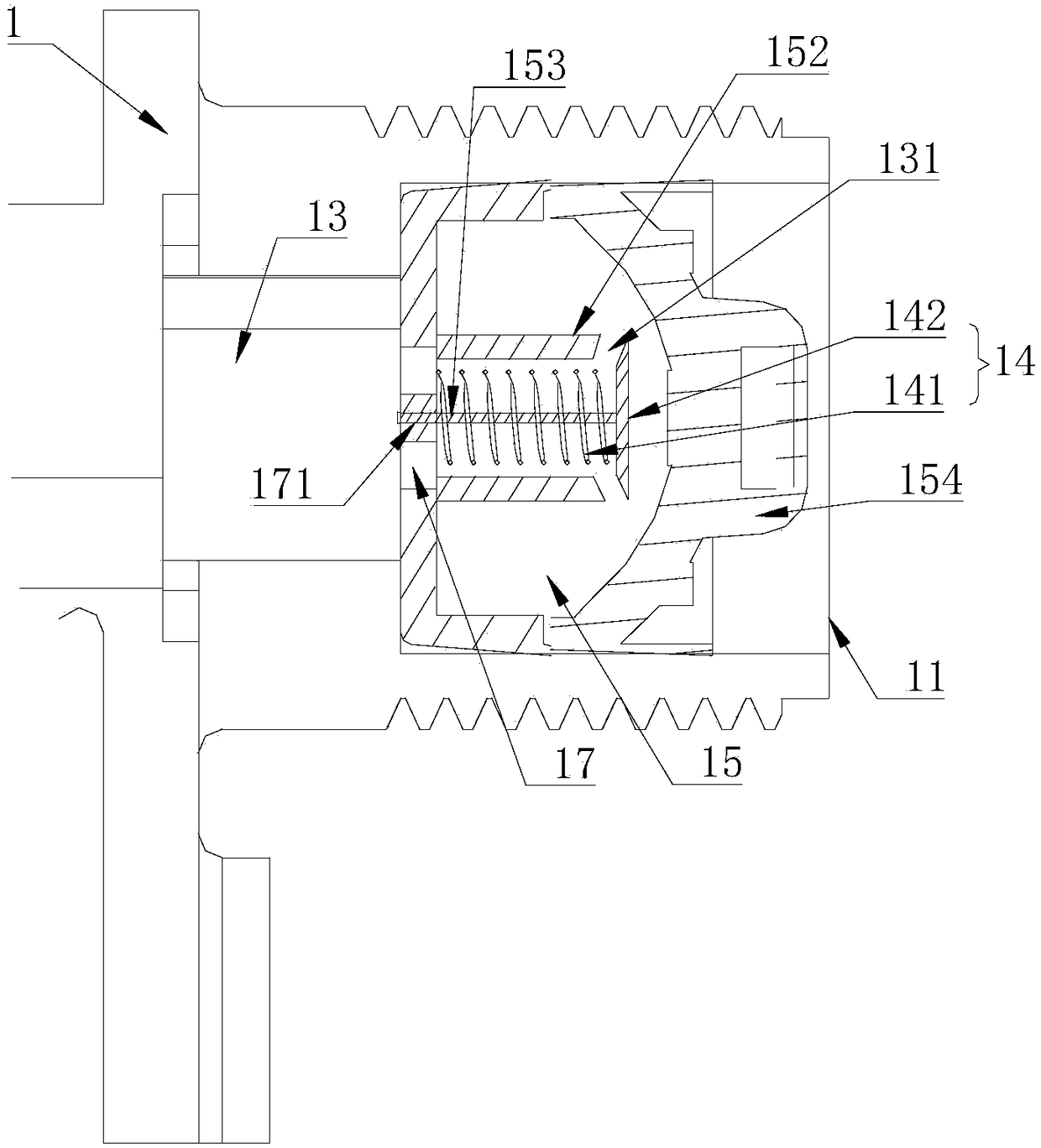

[0035] Such as Figure 1 to Figure 2As shown, a water inlet valve described in this embodiment includes a valve body 1, and the valve body 1 is provided with a water inlet 11 and a water outlet 12, and the water inlet 11 and the water outlet 12 pass through a throttling passage 13 connected, the water inlet 131 of the throttling channel 13 is provided with an elastic element 14 that adjusts the opening of the water inlet 131 of the channel according to the change of the water flow pressure of the water inlet 11, and the water pressure difference between the water inlet 11 and the water outlet 12 overcomes the elasticity The elasticity of the element 14 is used to adjust the opening of the throttling passage 13 to change the cross-sectional area of the throttling passage 13 to control the water flow rate of the water outlet 12 .

[0036] In this embodiment, the elastic element 14 includes a spring 141 and a throttling plate 142, one end of the spring 141 is fixedly connected ...

Embodiment 2

[0048] Such as Figures 1 to 2 As shown, a washing machine described in this embodiment includes a water inlet valve, the water inlet valve is arranged between the washing machine and the water supply system, the water inlet 11 of the water inlet valve is connected to the water supply system, and the water inlet valve The water outlet 12 of the valve is communicated with the bucket of the washing machine to control and adjust the water intake in the bucket of the washing machine.

[0049] In this embodiment, a washing machine includes a water tub. A water inlet valve is provided between the water inlet 11 of the water tub and the water supply system. An electromagnetic component 161 is provided in the water inlet valve to automatically control the opening of the water inlet valve. close, the washing water in the external water supply system flows into the bucket, the water inlet 11 of the water inlet valve is connected to the water supply system, the water outlet 12 of the wat...

Embodiment 3

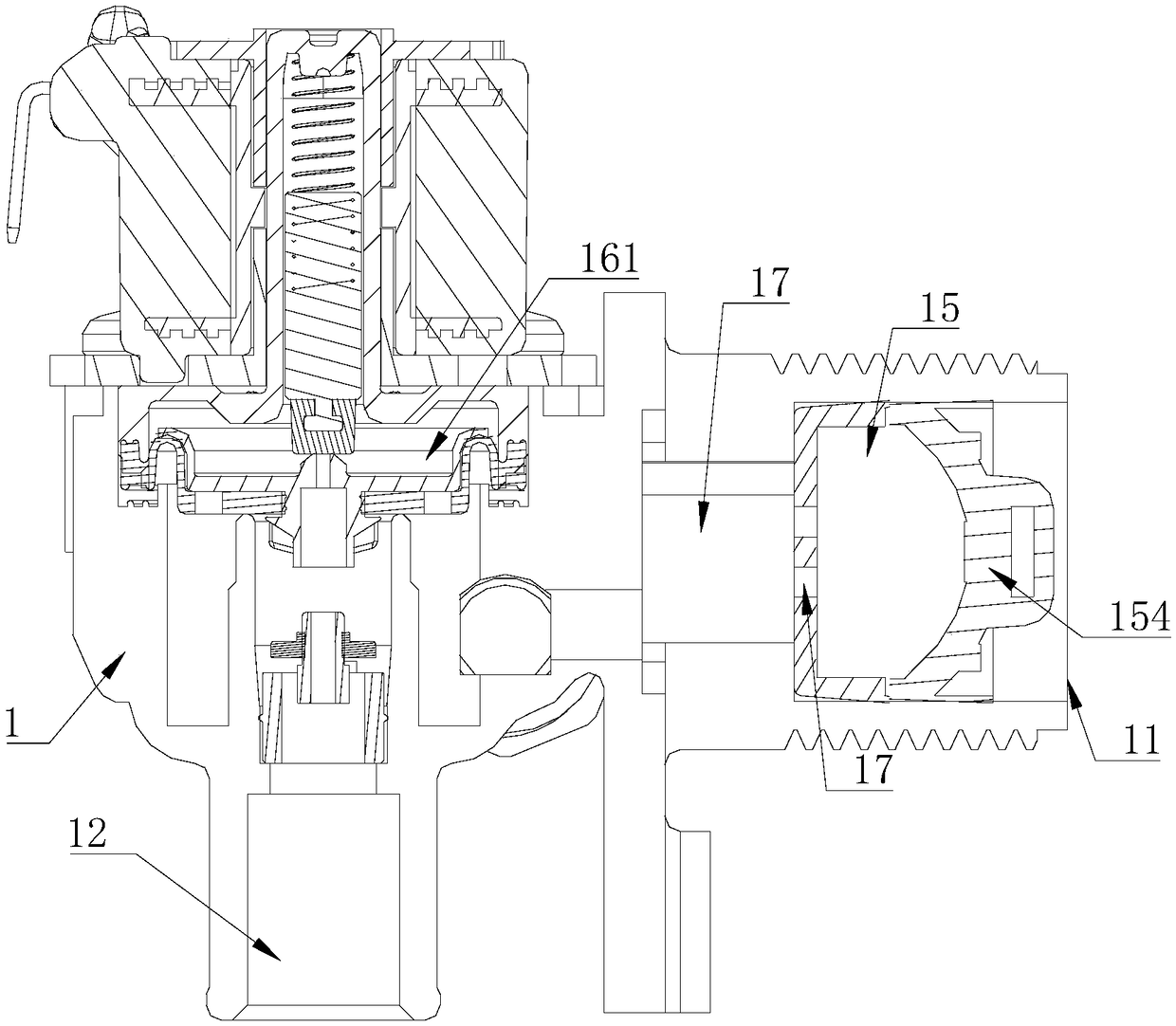

[0060] Such as image 3 and Figure 4 As shown, the existing water inlet valve in the background technology cannot achieve constant water output per unit time, or because the structure of the flow regulating component is relatively simple, it is easily affected by the material itself, manufacturing differences, assembly, etc. 1. In the case of different water outlet pipeline connections, the water inlet valve that realizes the constant water outlet flow per unit time. In the prior art, the water inlet 11 of the water inlet valve that cannot be adjusted for flow is provided with the elastic element 14 described in the present invention. Existing In the technology, the water inlet 11 of the flow adjustment water inlet valve is realized by a rubber member 18, and replaced with the elastic member 14 described in the present invention.

[0061] In this embodiment, according to the flow control principle and structure of the present invention, on the basis of retaining the original ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com