Alkali flocculation harvest and cyclic microalgae culture method

A technology of circulating culture and microalgae, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of unguaranteed cycle culture, damage to microalgae, and generation of cell fragments, etc., to achieve the solution of microalgae cultivation Effluent and waste discharge, costly to resolve, effects of reduced harvest costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1 circulation culture system

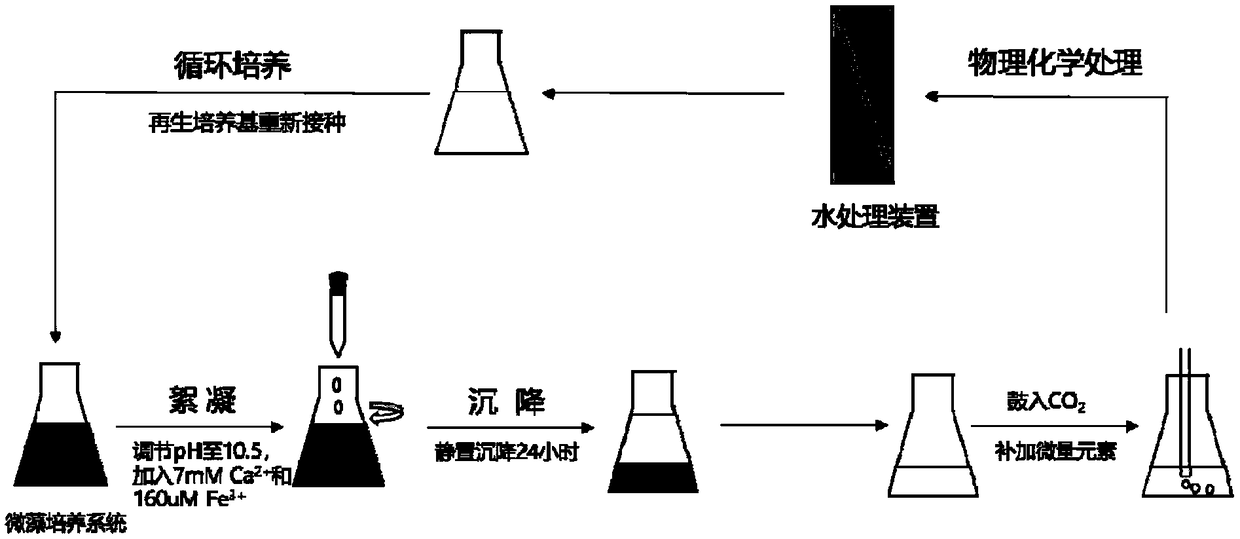

[0054] A method for alkali flocculation harvesting and circular culture of microalgae, the whole process is as follows figure 1 As shown, the method includes the following steps:

[0055] (1) The microalgae cultivation system is a bicarbonate-based carbon capture and microalgae cultivation system (BICCAPS), which utilizes a medium containing a certain concentration of bicarbonate to cultivate microalgae, and the cultured microalgae is Dunaliella salina, The medium formula is shown in Tables 1 and 2. The culture system is a 1L Erlenmeyer flask, used as a photobioreactor, the culture volume is 300mL, the inoculation density is 0.1g / L, the light intensity is 4000Lux, the temperature is 25°C, and the initial pH The value is 8.5, and the pH value is 10.3 after the cultivation ends; when the microalgae is cultivated to harvestable (0.8g / L), 50% of the volume of the algae liquid in the Erlenmeyer flask is taken out;

[0056] (2) Adju...

Embodiment 2

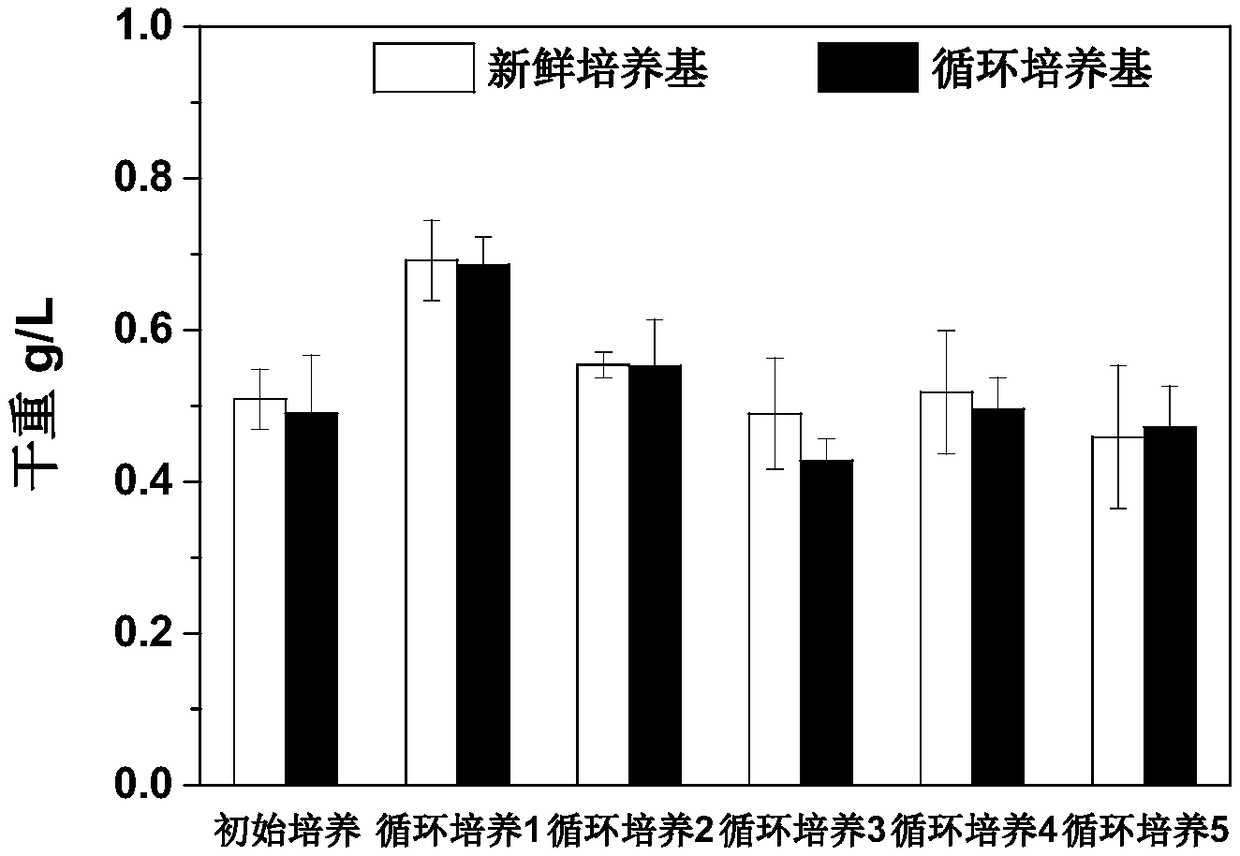

[0067] Embodiment 2: the circulating culture system of filter membrane treatment circulating fluid

[0068] The circulating fluid that is not treated cannot be reused for culturing microalgae. In this example, the semi-continuous microalgae circulation culture system of Example 1 is used to cultivate Dunaliella salina. The medium formula is shown in Table 1 and Table 2. The circulation culture time is 18 days, the light intensity is 3000 Lux, and the initial inoculum size is 0.1g. / L, the temperature was 25°C, the initial pH value was 8.5, and the pH value was 10.37 after the cultivation. The circulating medium (experimental group) was compared with fresh medium (control group), ie the same volume of fresh medium was added when the medium was circulated. Three days after inoculation, 50% of the medium was removed for circulation, and the removed circulation medium was bubbled with CO 2, reduce the pH to 8.50, add other nutrient salts (except sodium chloride and sodium bicarb...

Embodiment 3

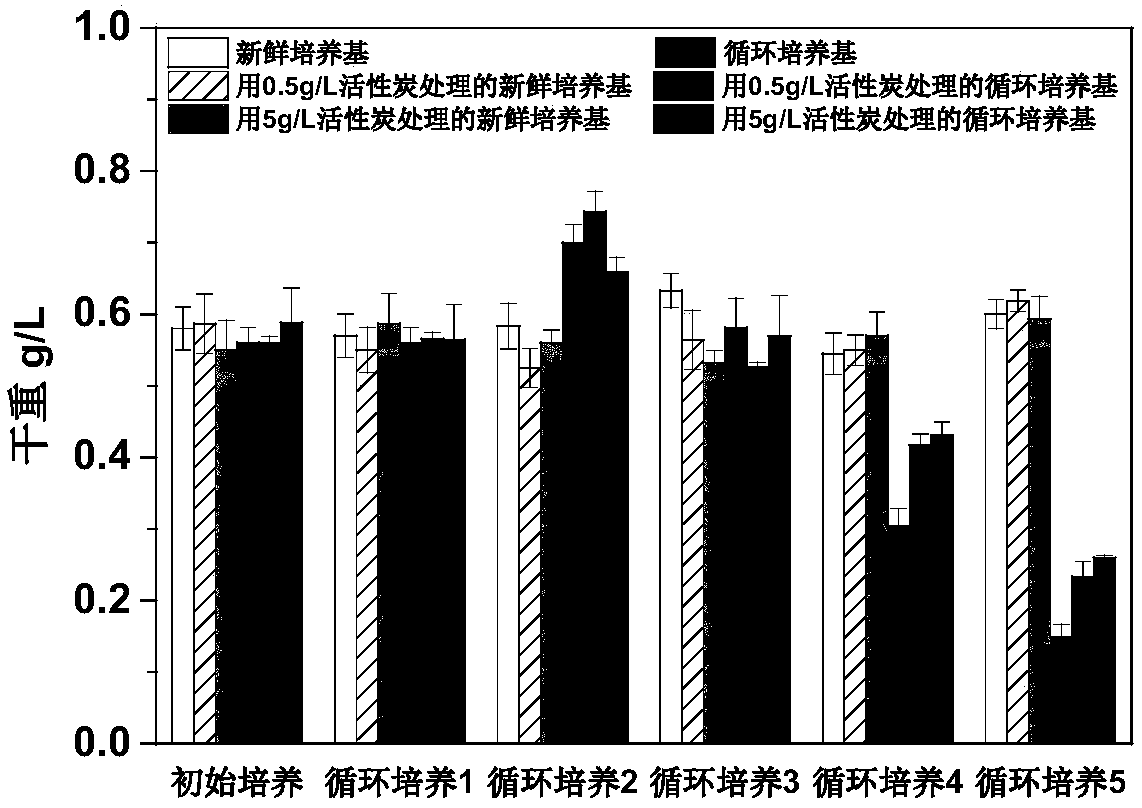

[0069] Embodiment 3: the circulating culture of activated carbon treatment circulating liquid

[0070] In this example, the semi-continuous microalgae circulation culture system of Example 1 is used to cultivate Dunaliella salina. The medium formula is shown in Table 1 and Table 2. The circulation culture time is 18 days, the light intensity is 3000 Lux, and the initial inoculation amount is 0.1g. / L, the temperature was 25°C, the initial pH value was 8.5, and the pH value was 10.3 after the cultivation. After each circulation of the circulating medium, 50% of the volume of the circulating liquid was taken, treated with 0.5 and 5 g / L activated carbon for 24 hours, and then removed by centrifugation, and then the circulating liquid was bubbled into CO 2 , reduce the pH to 8.5, add other nutrient salts (except sodium chloride and sodium bicarbonate) to the initial medium concentration, and the specific addition amounts are: KNO 3 , 0.005mol / L; KH 2 PO 4 ·3H 2 O, 0.000237mol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com