Thin-walled high-strength crop straw gasifier

A crop straw, high-strength technology, which is applied in the gasification process, the mechanical details of the gasification device, and the manufacture of combustible gas, etc., can solve the problem that the sealing of the furnace wall connection cannot be guaranteed, affecting the service life and safety of the gasifier. Insufficient protection and other problems to achieve the effect of increasing practicability, improving service life and safety performance, and increasing air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

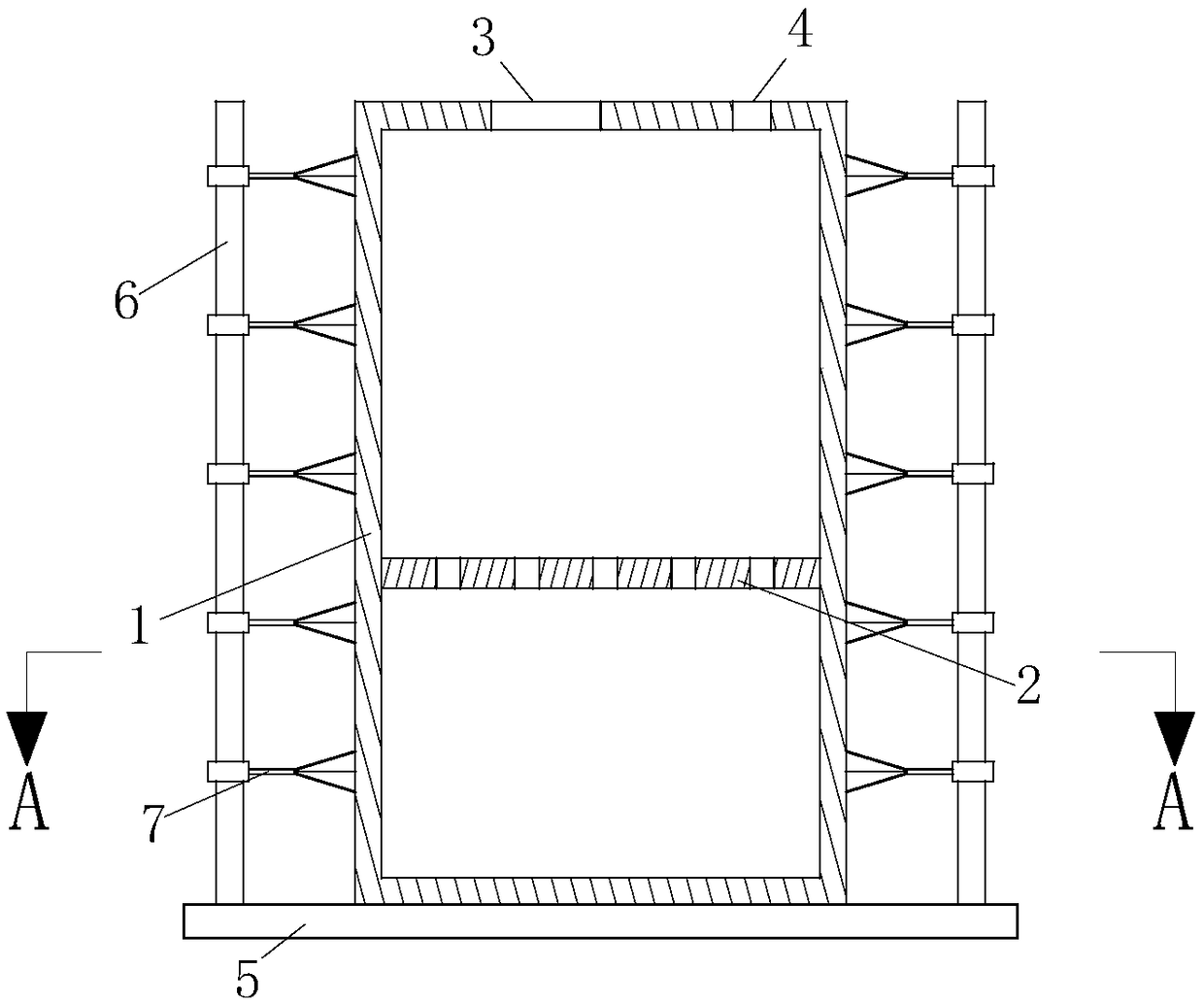

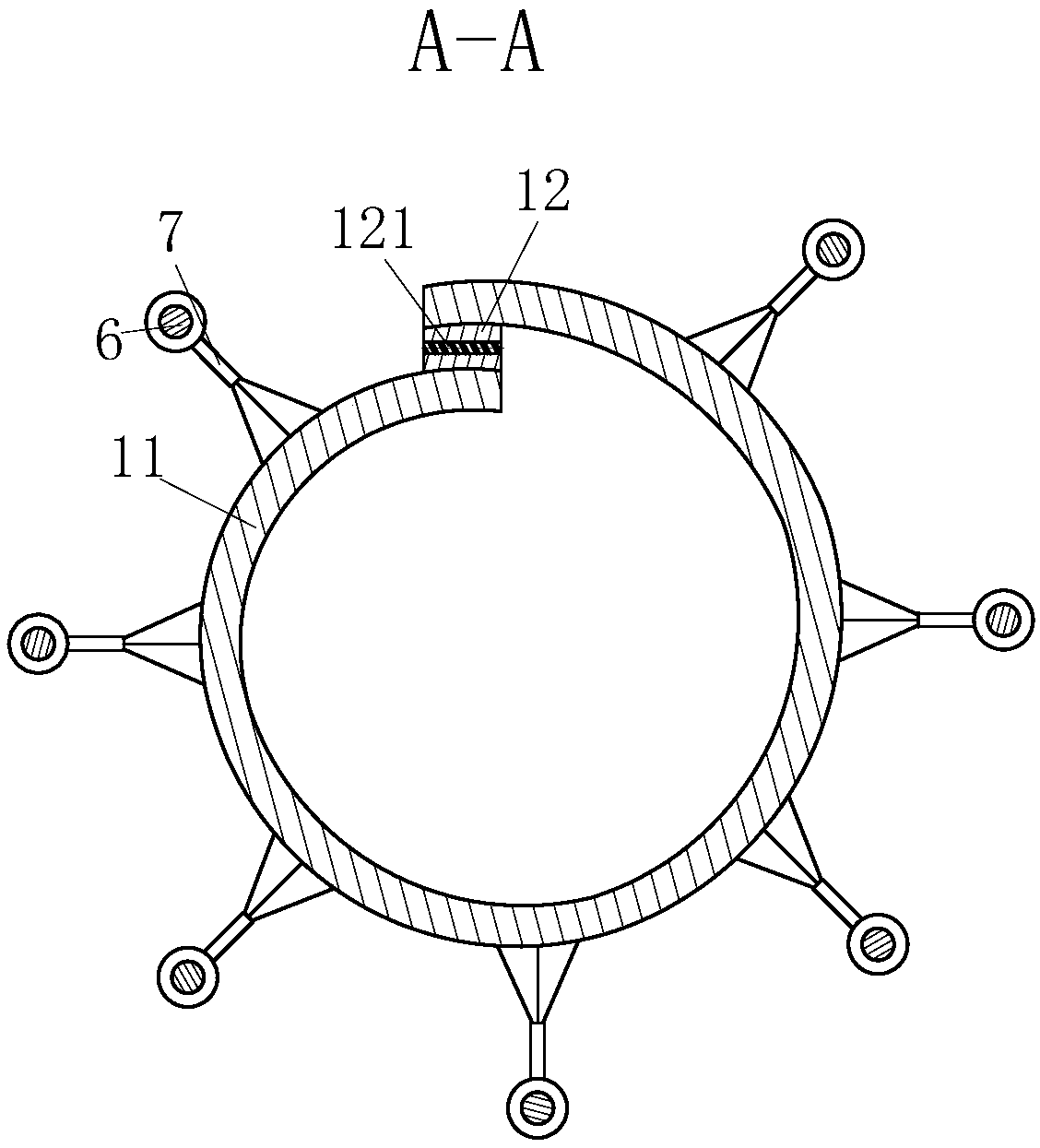

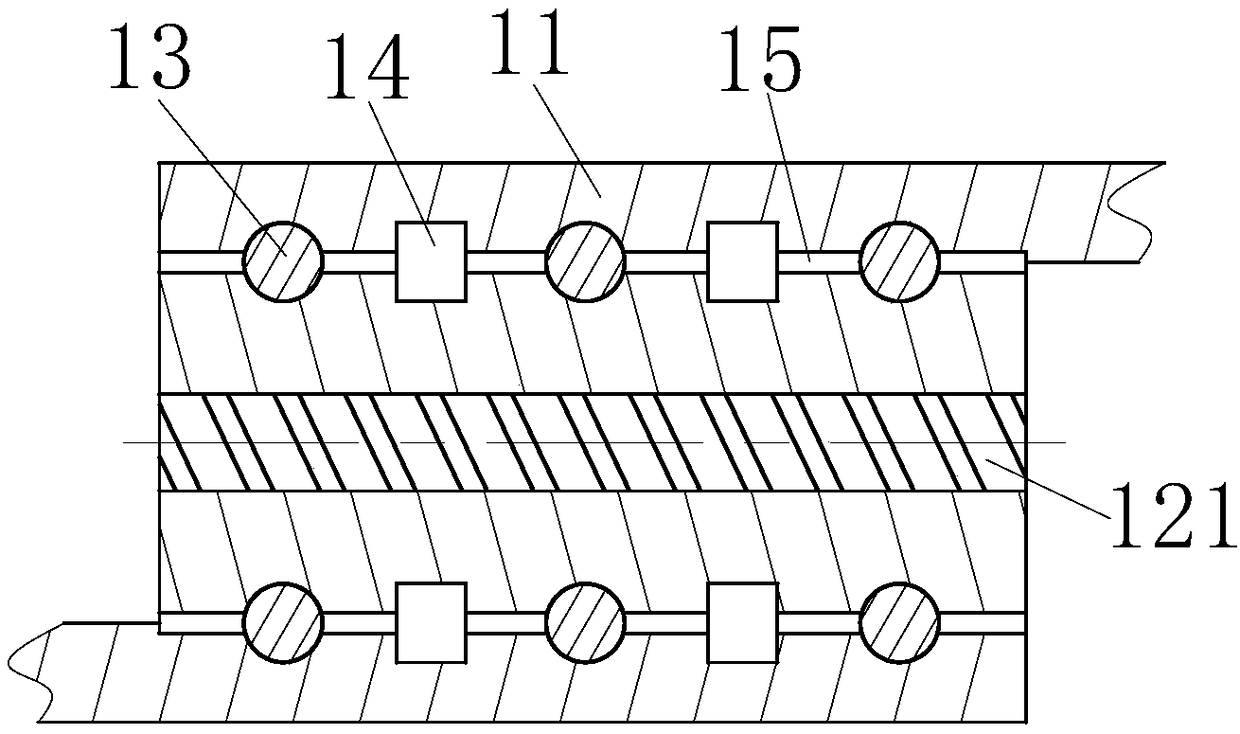

[0020] use Figure 1-Figure 4 The structure of the thin-walled high-strength crop straw gasifier according to one embodiment of the present invention will be described as follows.

[0021] Such as figure 1 and figure 2 As shown, a thin-walled high-strength crop straw gasification furnace according to the present invention includes a furnace body 1, a fire grate 2, a feed port 3 and a gas outlet 4; the fire grate 2 is located inside the furnace body 1, and the furnace The grate 2 is used to pile up the crop straw, and the grate 2 divides the interior of the furnace body 1 into two parts, so that the air in the lower part of the grate 2 enters the upper part of the grate 2 to react with the crop straw, which improves the reaction efficiency and makes The reaction is more sufficient; the feed port 3 is located above the furnace body 1, and the feed port 3 is used to insert crop straw into the furnace body 1; the gas outlet 4 is located above the furnace body 1, and the gas out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com