Washing-endurance and water-repelling synergist as well as preparation method and application thereof

A technology of washing resistance and synergist, which is applied in the direction of fiber type, textile and paper making, fiber treatment, etc., can solve the problems of reduced flame retardancy, etc., and achieve the effect of increasing crosslinking degree, active reaction characteristics, and simple and convenient preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

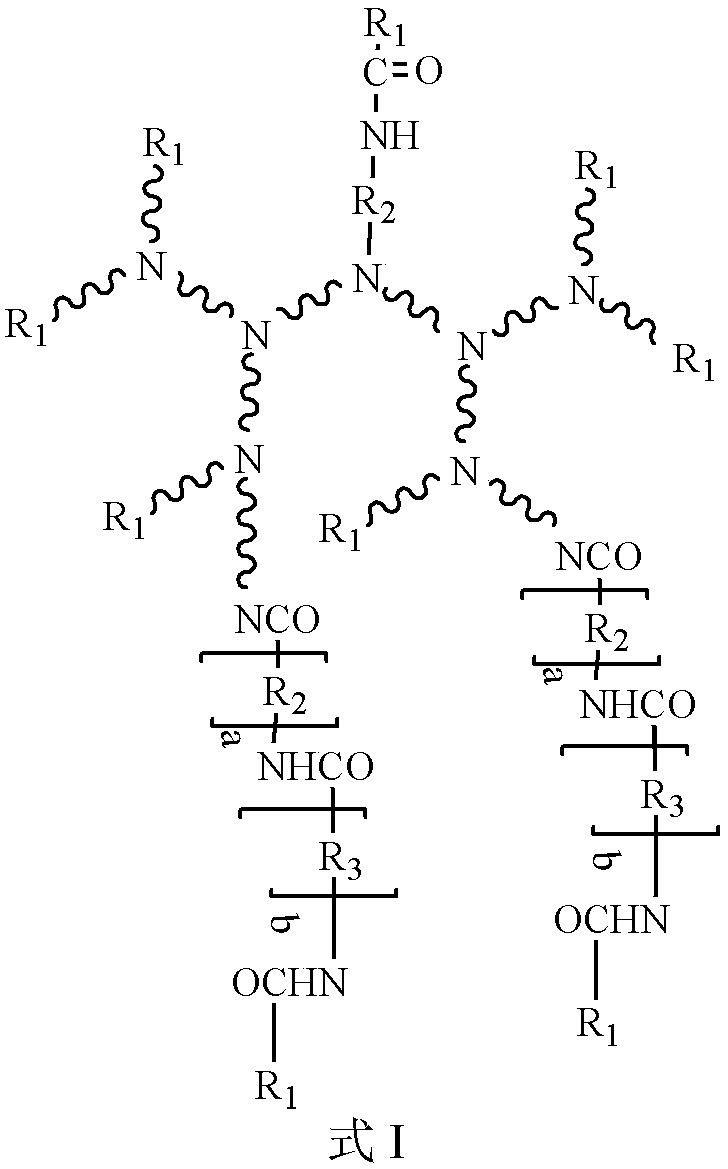

Method used

Image

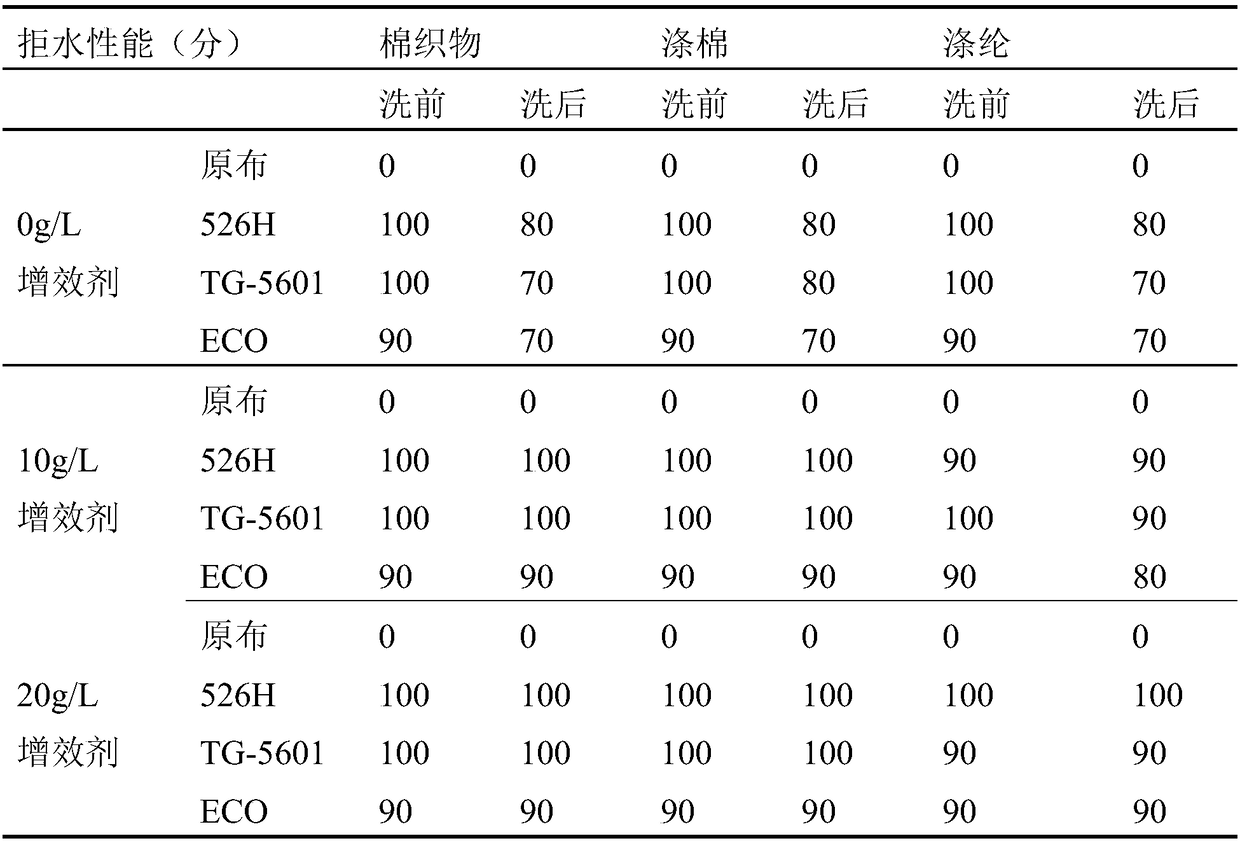

Examples

Embodiment 1

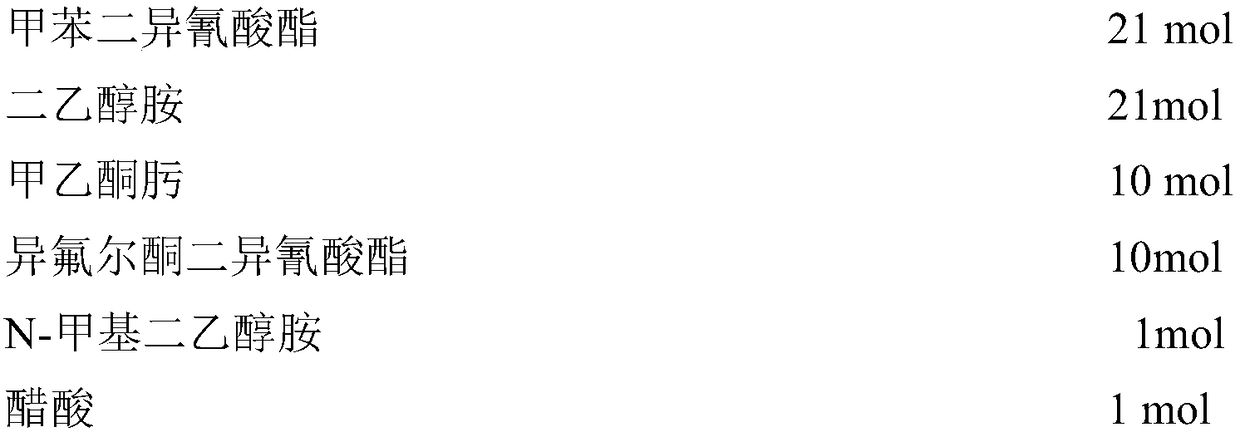

[0047] The formula of washing-resistant water-repellent synergist is as follows:

[0048]

[0049] 1. Preparation

[0050] Each raw material in the above formula is prepared according to the preparation method of the present invention to obtain a washing-resistant water-repellent synergist.

[0051] The specific preparation method is:

[0052] Under the protection of inert gas nitrogen, 21mol toluene diisocyanate and 21mol diethanolamine were reacted in an ice-water bath at -5°C for 0.5h, and then heated to 50°C for another 6h to obtain an -NCO group at one end and -OH at both ends. Group branched prepolymer I, add 1mol methyl ethyl ketone oxime to prepolymer I, react at 70°C for 1 hour to obtain prepolymer II; mix 10mol isophorone diisocyanate and 1mol N-methyldiethanolamine evenly, React at 70°C for 2 hours, then add 9 mol of methyl ethyl ketone oxime, react at 60°C for 2 hours, cool down to 40°C to obtain prepolymer III with -NCO group at one end; mix prepolymer II and...

Embodiment 2

[0060] The formula of washing-resistant water-repellent synergist is as follows:

[0061]

[0062] 1. Preparation

[0063] Each raw material in the above formula is prepared according to the preparation method of the present invention to obtain a washing-resistant water-repellent synergist.

[0064] The specific preparation method is:

[0065] Under the protection of inert gas nitrogen, react 21mol hexamethylene diisocyanate and 21mol diethanolamine in -5°C ice-water bath for 0.5h, then raise the temperature to 50°C and react for 6h to obtain -NCO group at one end, and It is a branched prepolymer I with -OH group, add 1mol methyl ethyl ketone oxime to the prepolymer I, react at 70°C for 1h, and obtain the prepolymer II; mix 10mol isophorone diisocyanate, 1mol N-methyldiethanolamine Mix well, react at 70°C for 2 hours, then add 9mol methyl ethyl ketone oxime, react at 60°C for 2 hours, cool down to 40°C, and obtain prepolymer III with -NCO group at one end; mix prepolymer ...

Embodiment 3

[0074] The formula of washing-resistant water-repellent synergist is as follows:

[0075]

[0076] 1. Preparation

[0077] Each raw material in the above formula is prepared according to the preparation method of the present invention to obtain a washing-resistant water-repellent synergist.

[0078] The specific preparation method is:

[0079] Under the protection of inert gas nitrogen, react 21mol hexamethylene diisocyanate and 21mol diethanolamine in -5°C ice-water bath for 0.5h, then raise the temperature to 50°C and react for 6h to obtain -NCO group at one end, and It is a branched prepolymer I with -OH group, add 1mol methyl ethyl ketone oxime to the prepolymer I, and react at 70°C for 1h to obtain the prepolymer II; mix 10mol isophorone diisocyanate, 1mol dimethylolpropane Mix the acid evenly, react at 70°C for 2 hours, then add 9 mol of methyl ethyl ketone oxime, react at 60°C for 2 hours, cool down to 40°C, and obtain prepolymer III with -NCO group at one end; com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com