Processing method of ceramic product with good stability

The technology of a ceramic product and a processing method, which is applied to the processing field of ceramic products, can solve the problems of easy damage and fall off of the glaze layer, low overall strength and low quality, etc., and achieve the effects of not easy to peel off, reasonable matching and stable glaze layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for processing ceramic products with good stability, comprising the steps of:

[0034] (1) Preparation of functional fillers:

[0035] a. Mix formaldehyde and cyanuric acid amide according to the mass ratio of 1:1.2 and put them into the reaction kettle, then add 1.8% of the total mass of boric acid and 0.35% of ferrocene to obtain mixture A, and then mix the mixture A Adjust the pH value to 8.0, heat to keep the temperature in the reactor at 37°C, and stir at a speed of 260 rpm for 30 minutes before standby;

[0036] b. Add 4% polyvinyl alcohol, 1.5% phenol, 2% natron, and 0.7% manganese sulfate to the total mass of mixture A in the reaction kettle treated in operation a, then raise the temperature to 46°C to Take it out after stirring at a speed of 400 rpm for 45 minutes, and then mix it evenly with deionized water 90 times its total mass to obtain mixture B for later use;

[0037] c. Put the montmorillonite into the acid solution for soaking for 3 minutes,...

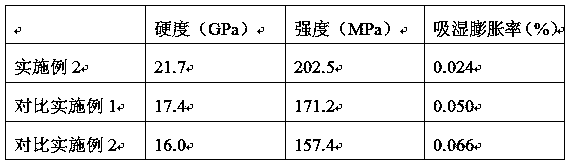

Embodiment 2

[0057] A method for processing ceramic products with good stability, comprising the steps of:

[0058] (1) Preparation of functional fillers:

[0059] a. Mix formaldehyde and cyanuric diamide according to the mass ratio of 1:1.4 and put them into the reaction kettle, then add 2.1% of the total mass of boric acid and 0.4% of ferrocene to obtain mixture A, and then mix the mixture A Adjust the pH value to 8.3, heat to keep the temperature in the reactor at 40°C, and stir at a speed of 270 rpm for 32 minutes before standby;

[0060] b. Add 5% polyvinyl alcohol, 1.7% phenol, 2.5% natron, and 1.1 manganese sulfate to the reaction kettle of the total mass of mixture A, then raise the temperature to 48° C. Take it out after 47 minutes of stirring at the speed of rotation per minute, and then mix it uniformly with deionized water with a total mass of 93 times to obtain mixture B for subsequent use;

[0061] c. Put the montmorillonite into the acid solution for soaking for 4 minutes,...

Embodiment 3

[0081] A method for processing ceramic products with good stability, comprising the steps of:

[0082] (1) Preparation of functional fillers:

[0083] a. Formaldehyde and cyanuric acid amide are mixed according to the mass ratio of 1:1.5 and then put into the reaction kettle, and then 2.4% of the total mass of boric acid and 0.45% of ferrocene are added to obtain the mixture A, and then the mixture A is mixed Adjust the pH value to 8.5, heat to keep the temperature in the reactor at 41°C, and stir at a speed of 280 rpm for 35 minutes before standby;

[0084] b. Add 6% polyvinyl alcohol, 2% phenol, 3% natron, and 1.2% manganese sulfate of the total mass of mixture A to the reaction kettle after operation a, and then raise the temperature to 50°C to Take it out after stirring at a speed of 450 rpm for 50 minutes, and then mix it evenly with deionized water with a total mass of 95 times to obtain mixture B for later use;

[0085] c. Put the montmorillonite into the acid solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com