Micro-aerobic environment moving bed biological film reaction device and method for utilizing same to treat coal gas wastewater

A technology of moving bed biofilm and reaction device, which is applied in the field of water treatment device and coal gas wastewater treatment, can solve the problems of long hydraulic retention time, high treatment cost and poor effect, and achieve small sludge output and residual waste Less amount of sludge, good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

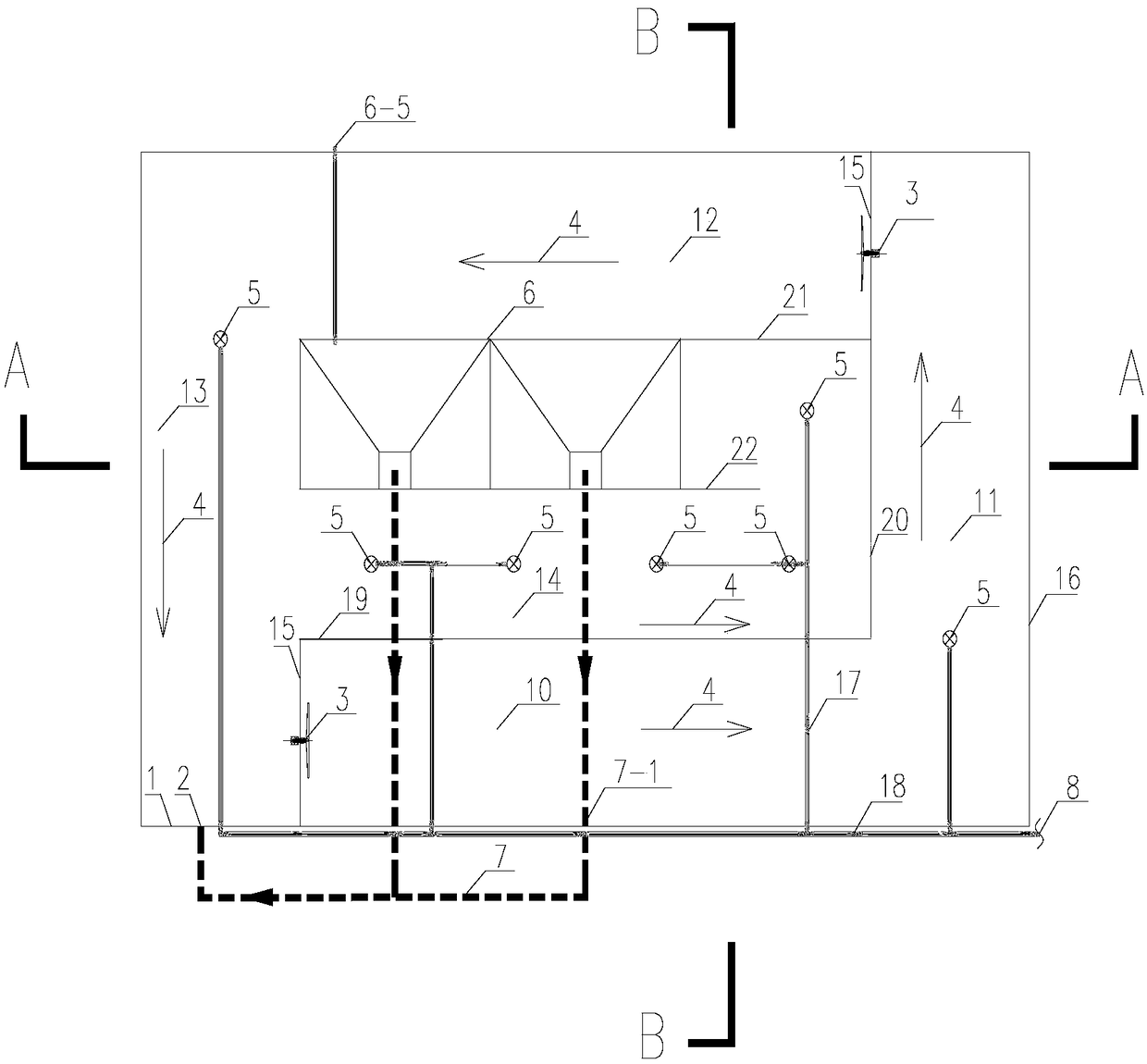

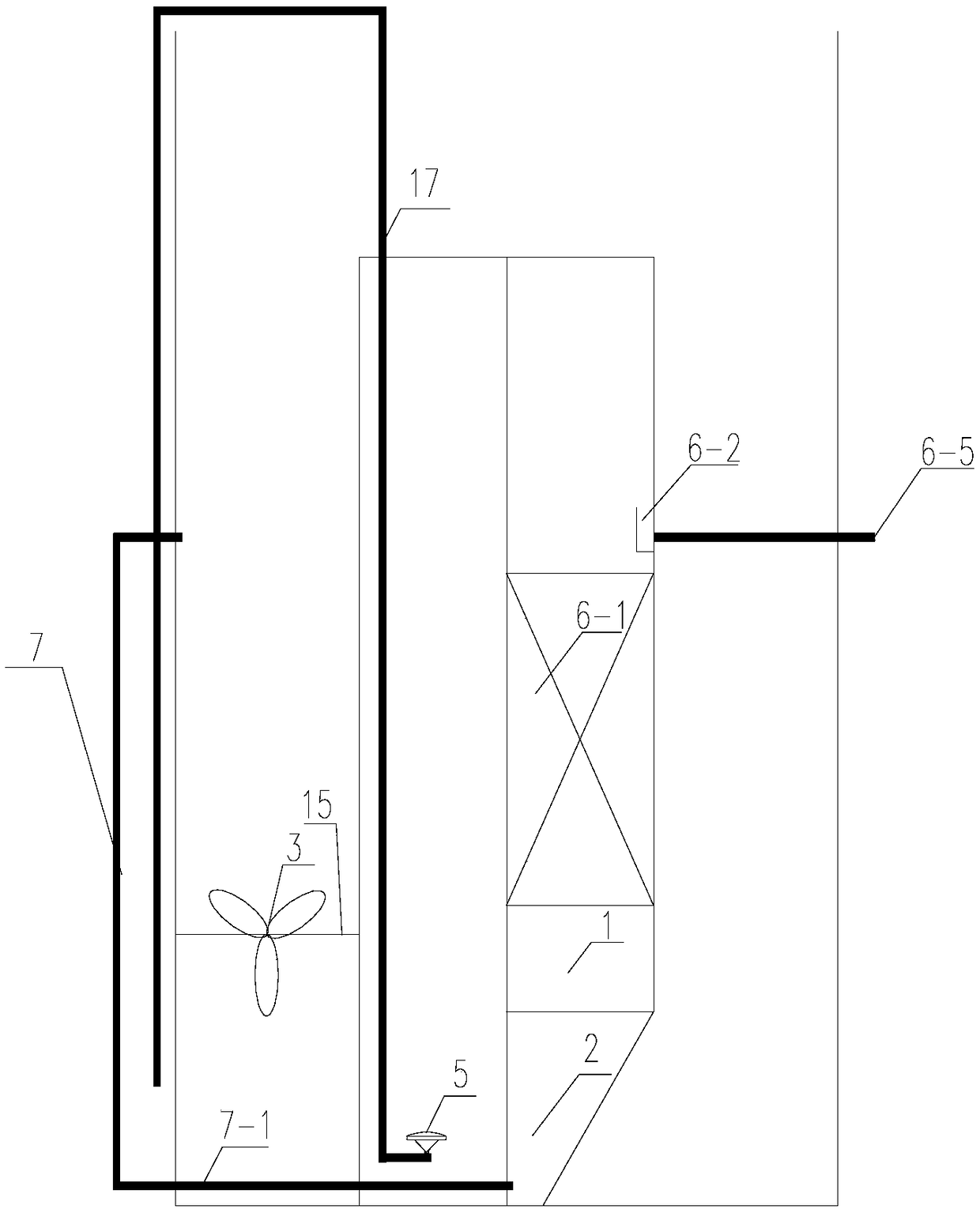

[0025] Specific implementation mode one: combine figure 1 Describe this embodiment mode, a kind of micro-oxygen environment moving bed biofilm reaction device of this embodiment comprises tank body 16, two underwater thrusters 3, a plurality of aeration heads 5, sludge return pipe main pipe 7, air pump 8, Settling tank 6, pusher fixing rod 15, first partition wall 19, second partition wall 20, third partition wall 21 and fourth partition wall 22;

[0026] Described pond body 16 is provided with sedimentation tank 6 and four partition walls, and four partition walls are arranged on the outside of sedimentation tank 6; Described four partition walls are respectively the first partition wall 19, the second partition wall 20. The third partition wall 21 and the fourth partition wall 22; the pool body 16 is divided into five corridors by the sedimentation tank 6 and four partition walls; the five corridors are respectively the first corridor 10 and the second corridor 11. The thir...

specific Embodiment approach 2

[0044] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the push flow direction of the underwater pusher 3 is along the outlet end of the first corridor 10, the inlet end of the second corridor 11, The exit end of the second corridor 11, the entrance end of the third corridor 12, the exit end of the third corridor 12 and the entrance end of the fourth corridor 13 direction push flow, the first corridor 10, the second corridor 11 , The third corridor 12 and the fourth corridor 13 are rotary corridors in the form of oxidation ditch, which can rotate and circulate. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

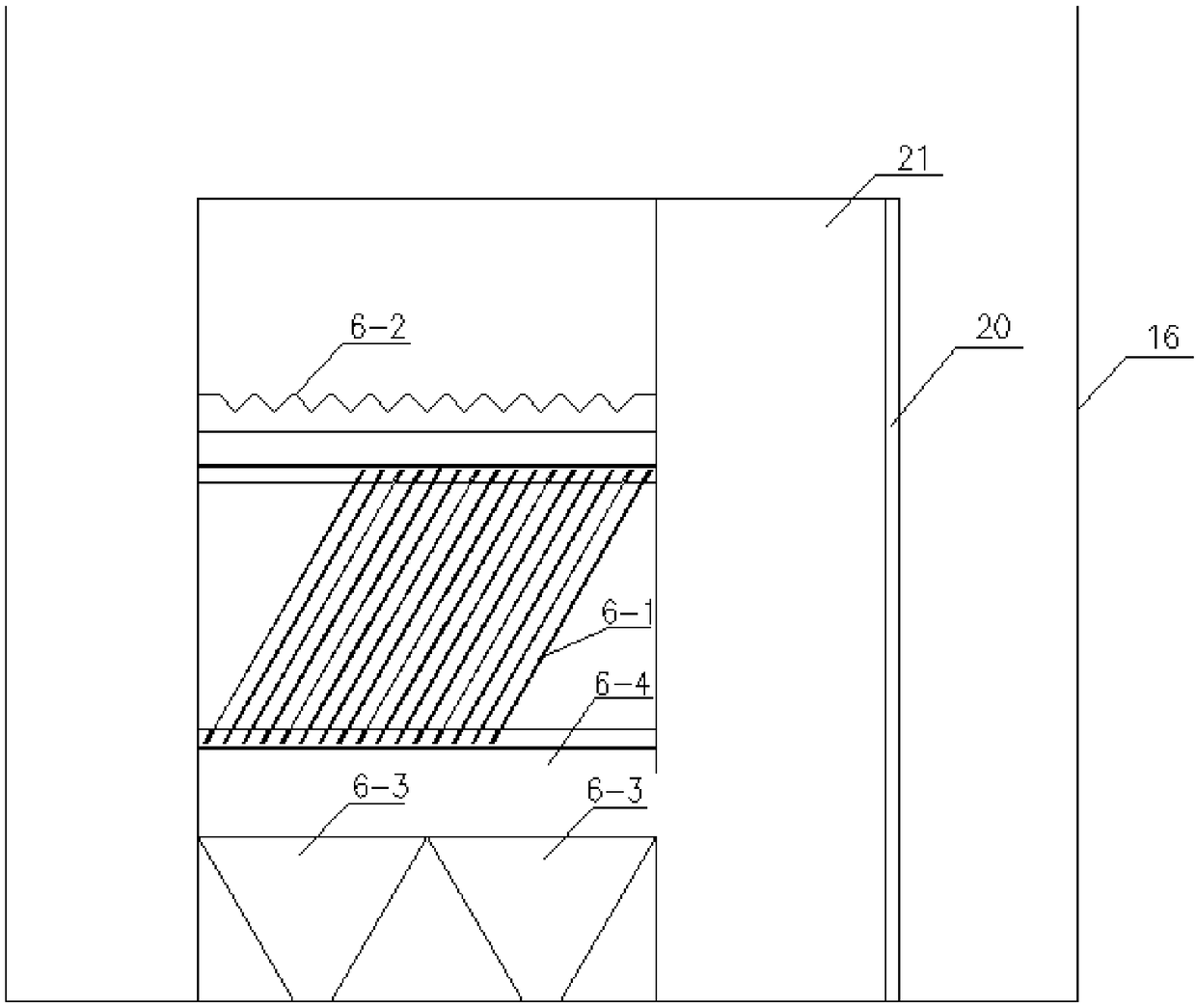

[0045] Specific implementation mode three: combination Figure 1 ~ Figure 3 Describe this embodiment, the difference between this embodiment and specific embodiment 1 or 2 is: the sedimentation tank 6 is a slant plate sedimentation tank, the middle part of the slant plate sedimentation tank is a slant plate 6-1, and the slant plate 6- The upper part of 1 is the outlet weir 6-2, the lower part of the inclined plate 6-1 is provided with the sedimentation tank inlet area 6-4, and the lower part of the sedimentation tank inlet area 6-4 is provided with two mud storage tanks 6-3, and the sedimentation tank One end of the outlet pipe 6-5 of the pool communicates with the outlet weir 6-2, and the other end passes through the pool body 16. Other steps are the same as those in Embodiment 1 or 2.

[0046] Specific implementation mode four: combination Figure 1 ~ Figure 3 Describe this embodiment. The difference between this embodiment and one of the specific embodiments 1 to 3 is: th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com