A method of directly growing uniform rhenium diselenide nanosheets on a substrate electrode, modified electrodes and applications

A base electrode and rhenium diselenide technology, which is applied in chemical instruments and methods, inorganic chemistry, hydrogen production, etc., can solve the problem that rhenium diselenide cannot grow on the electrode, and achieve improved catalytic performance, simple process, The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

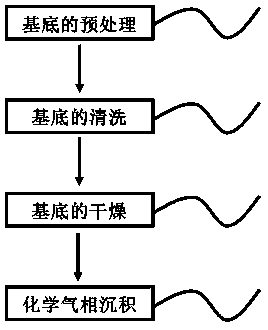

[0042] This embodiment provides a method for growing uniform rhenium diselenide nanosheets directly on carbon cloth electrodes, such as Figure 1~3 .

[0043] Step 101, cleaning of the substrate;

[0044] Step 102, processing of the substrate;

[0045] Step 103, drying of the substrate;

[0046] Step 104, growing uniform rhenium diselenide nanosheets on the carbon cloth by chemical vapor deposition;

[0047] In step 101: the carbon cloth is ultrasonicated for 5 minutes in the order of deionized water, acetone, ethanol, and deionized water, with ultrasonic power of 180 W and frequency of 40 KHz.

[0048] In step 102: soak the cleaned carbon cloth in the piranha solution at 120° C. for 2 hours to further clean the carbon cloth and increase the hydrophilicity of the carbon cloth. After natural cooling, rinse with deionized water.

[0049] In step 103: heat the treated carbon cloth on a heating platform at 80° C. for 10 minutes.

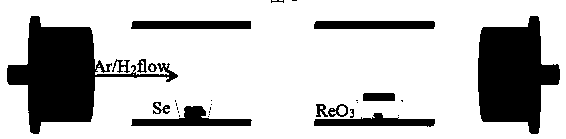

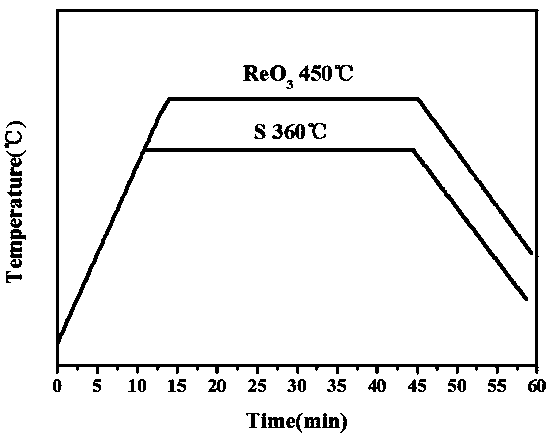

[0050] In step 104: use the chemical vapor d...

Embodiment 2

[0058] This embodiment provides a method for directly growing uniform rhenium diselenide nanosheets on carbon cloth electrodes. In the method provided in this embodiment, except that step 104 controls the growth temperature to 700° C., other steps and conditions are the same as those in Embodiment 1.

[0059] The rhenium diselenide nanosheets prepared in this embodiment, such as Figure 6 and Figure 7 .

Embodiment 3

[0061] This embodiment provides a method for directly growing uniform rhenium diselenide nanosheets on carbon cloth electrodes. In the method provided in this embodiment, it is the same as that in Embodiment 1 except that the growth temperature is controlled to be 600° C. in step 104 .

[0062] The rhenium diselenide nanosheets prepared in this embodiment, such as Figure 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com