Natural biofilm material moving method

A technology of biofilm and film materials, which is applied in the mobile field of natural biofilm materials, to reduce the suffering of patients, improve operating efficiency, and improve production and clinical operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

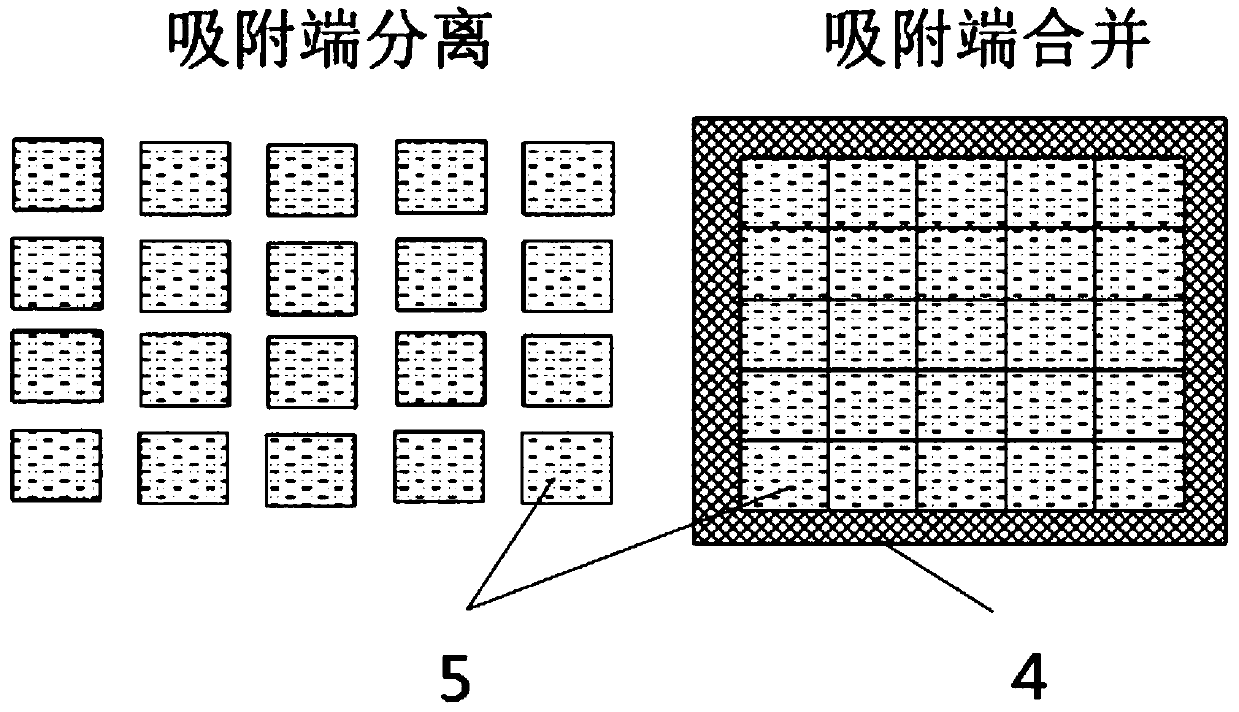

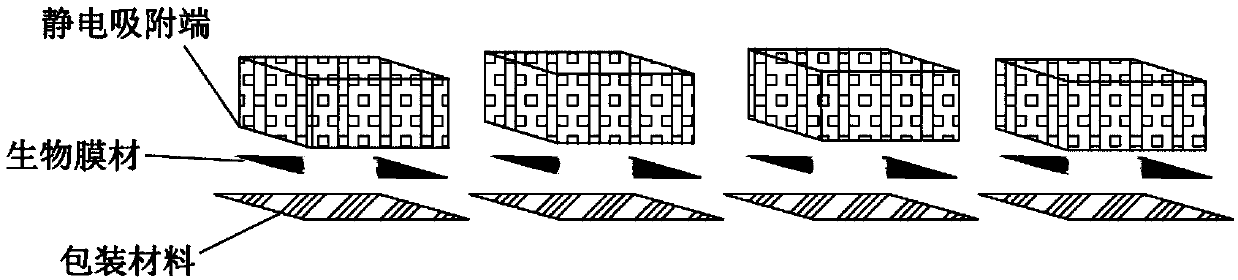

[0029] Static adsorption / elimination method: Lay the electrostatic adsorption cast sheet of the device horizontally to the dry SIS surface, activate the static electricity generation switch, and adjust the output voltage to 7kV to adsorb the SIS film. With the end surface of the adsorbed SIS membrane facing up, punch the SIS membrane to a diameter using a ceramic stamping knife Specification products (such as Figure 4 ). Start the static elimination function of the device to carry out the bagging operation.

[0030] The above operation was repeated continuously 50 times, and the operation time and product yield of each operation were recorded.

[0031] Routine operation: Place the dry SIS film horizontally on the stainless steel operating table, use a stamping knife to stamp the SIS film into a diameter Specification products, and then carry out bagging operation.

[0032] The above operation was repeated continuously 50 times, and the operation time and product yield o...

Embodiment 2

[0035] Static adsorption / elimination method: Lay the electrostatic adsorption cast piece of the device horizontally on the surface of the dry acellular dermal matrix, start the static electricity generation switch, and adjust the output voltage to 6kV to adsorb the acellular dermal matrix. With the end surface of the adsorbed acellular dermal matrix facing up, the acellular dermal matrix was punched into a product with a size of 3 cm×3 cm using a ceramic punching knife.

[0036] Move the adsorption end that has absorbed the dry acellular dermal matrix to the upper end of the packaging material, adjust the relative position and start the static elimination of the device, and the acellular dermal matrix will automatically fall off into the packaging material for bagging operation.

[0037] The above operation was repeated continuously 30 times, and the operation time and product yield of each operation were recorded.

[0038] Routine operation: place the dried acellular dermal m...

Embodiment 3

[0042] Static adsorption / elimination method: Lay the electrostatic adsorption cast piece of the device horizontally to the surface of the dry pericardium, activate the static electricity generation switch, and adjust the output voltage to 8kV to adsorb the pericardium. With the end surface of the adsorbed pericardium facing upward, the pericardium was punched into a product with a size of 1 cm×1 cm using a ceramic porous punching knife. Eliminate static electricity and carry out bagging operation.

[0043] The above operation was repeated 40 times continuously, and the operation time and product yield of each time were recorded.

[0044] Routine operation: Place the dried pericardium horizontally on the stainless steel operating table, punch the pericardium into a size of 1cm×1cm with a porous punching knife, and then carry out the bagging operation.

[0045] The above operation was repeated 40 times continuously, and the operation time and product yield of each time were rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com