Novel packaging box

A packing box and a new type of technology, applied in the field of packaging, can solve the problems of poor packaging strength and safety, poor compression resistance, and burst resistance, and recipients cannot be identified, etc., to achieve unique customer experience, good initial adhesion, The effect of improving the efficiency of unpacking and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

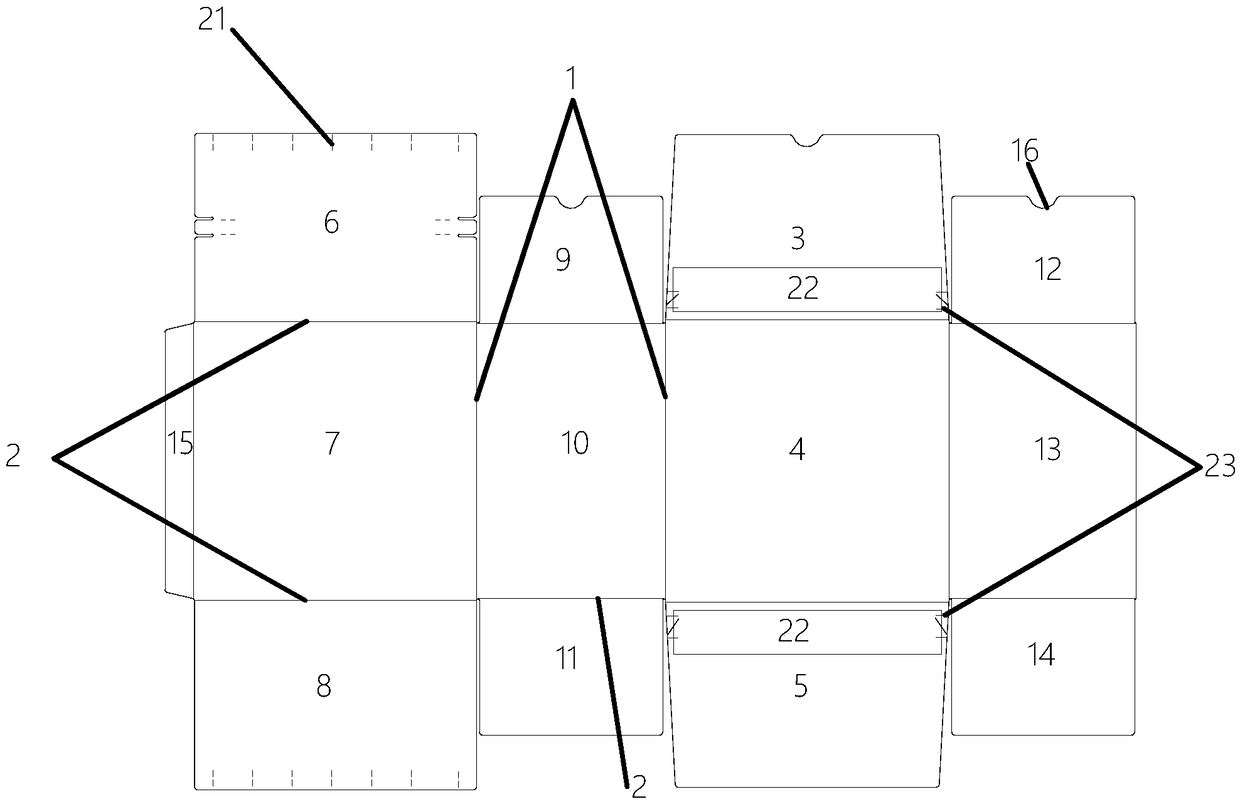

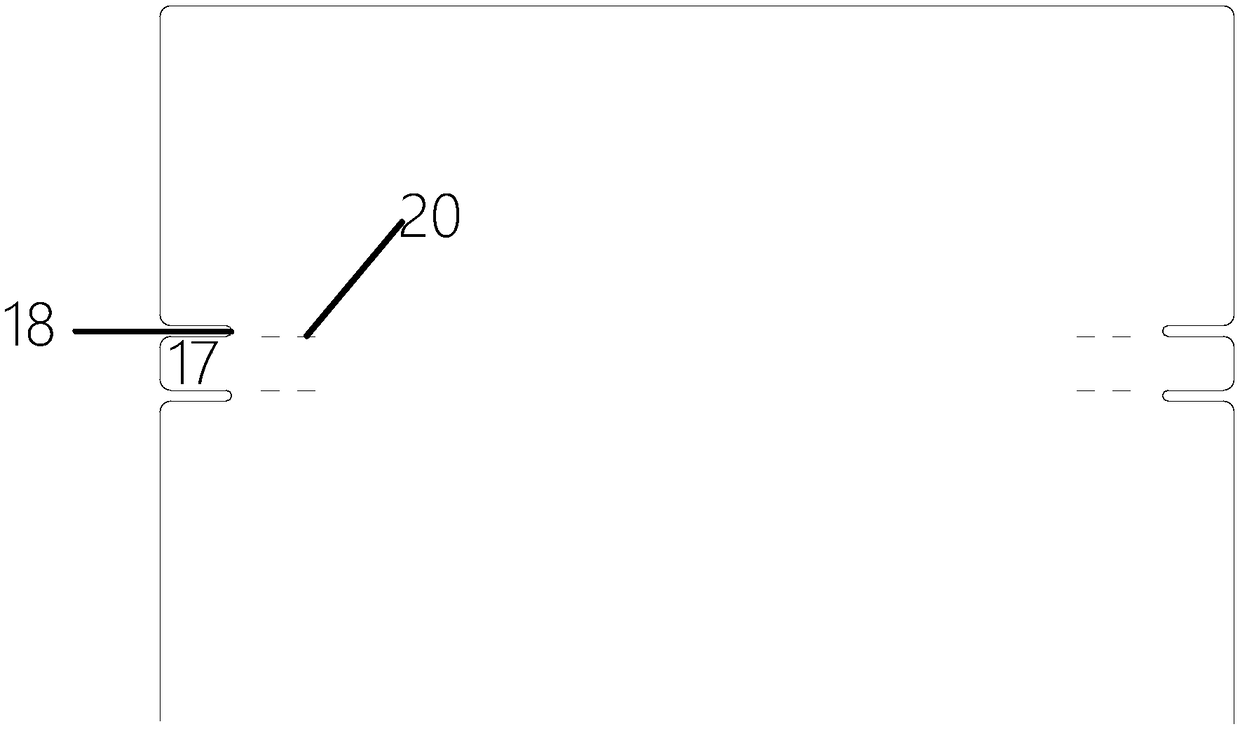

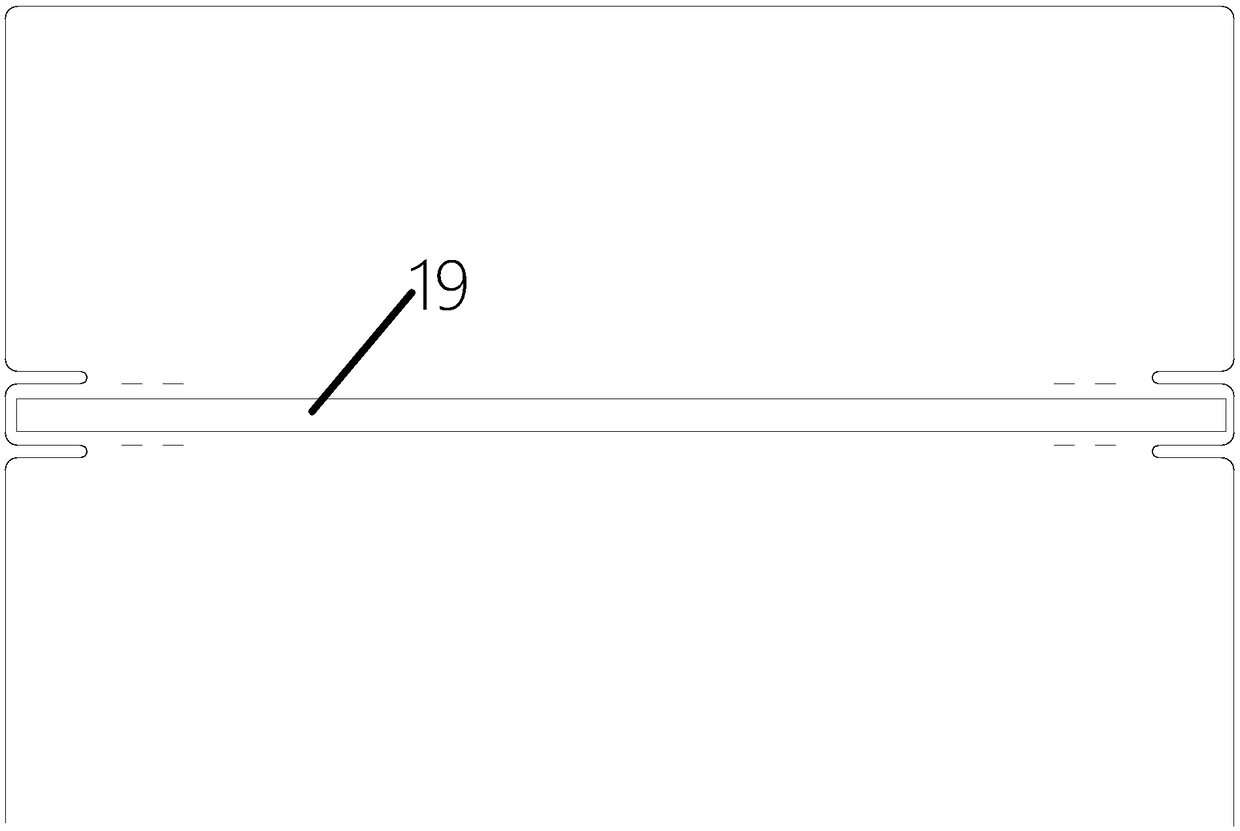

[0031] Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated. The following description and drawings illustrate specific embodiments of the invention sufficiently to enable those skilled in the art to practice them. The implementations described in the following exemplary embodiments do not represent all implementations consistent with this application. Rather, they are merely examples consistent with aspects of the application as recited in the appended claims. Portions and features of an embodiment may be included in or substituted for those of other embodiments. The scope of embodiments of the present application includes the full scope of the claims, and all available equivalents of the claims.

[0032] like Figure 1~4As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com