Magnetically soft alloy strip surface cleaning method and device thereof

A technology for soft magnetic alloy strips and strip surfaces, which can be used in grinding drive devices, metal processing equipment, and machine tools suitable for grinding workpiece planes, etc., and can solve problems such as low efficiency, high magnetic permeability, and low coercive force , to achieve the effect of improving efficiency, efficient removal and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

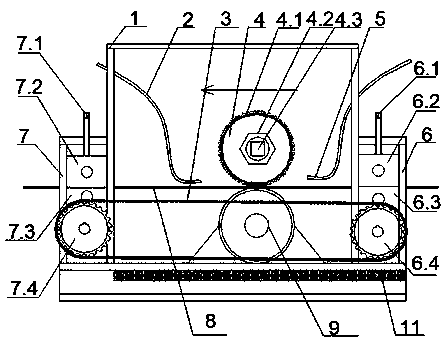

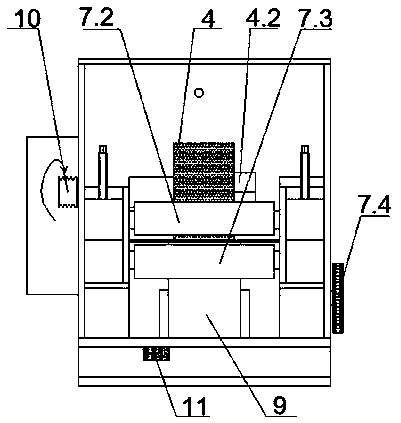

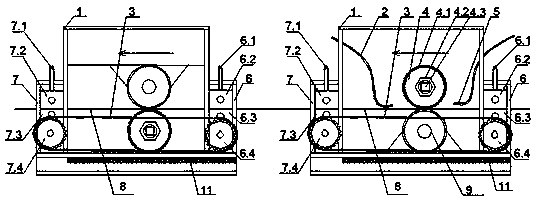

[0028] Such as figure 1 ,Such as figure 2 The shown method for cleaning the surface of a soft magnetic alloy strip and the removal device of the device include a box body 1, a left guide roller 7 on the left side of the box body 1, and a right guide roller 6 on the right side of the box body 1. A grinding device 4 is provided inside the body 1 , a middle guide roller 9 is provided below the grinding device 4 , spray pipes are provided on both sides of the grinding device 4 , and a groove 11 is provided at the bottom of the box body 1 . The grinding device 4 is a rotating shaft 4.3 and a louver grinding head 4.1 respectively from the inner layer to the outer layer, one side of the rotating shaft 4.3 is fixedly connected to the belt pulley 10, and the belt pulley 10 is connected to the motor, and the other side of the rotating shaft 4.3 is a nut 4.2 , the nut 4.2 is threadedly connected to the rotating shaft 4.3, the louver grinding head 4.1 is hollow cylindrical, and the louv...

Embodiment 2

[0031] On the basis of Embodiment 1, the lower surface of the soft magnetic alloy strip 8 can be cleaned by exchanging the positions of the grinding device 4 and the middle guide roller 9, and the soft magnetic alloy strip 8 is guided in the center by the grinding device 4 first. The device on the roller 9, then through the grinding device 4 on the bottom, the device on the middle guide roller 9 can realize the purpose of double-sided cleaning to the soft magnetic alloy strip 8 at one time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com