Material taking mechanism and automatic assembling device for assembling component

A technology of automatic assembly device and reclaiming mechanism, applied in assembly machines, metal processing, metal processing equipment, etc., can solve the problems of increasing assembly time and assembly cost, and the fixture cannot assemble magnetic parts and non-magnetic parts at the same time. Assembly time, reduced assembly costs, and reduced location requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

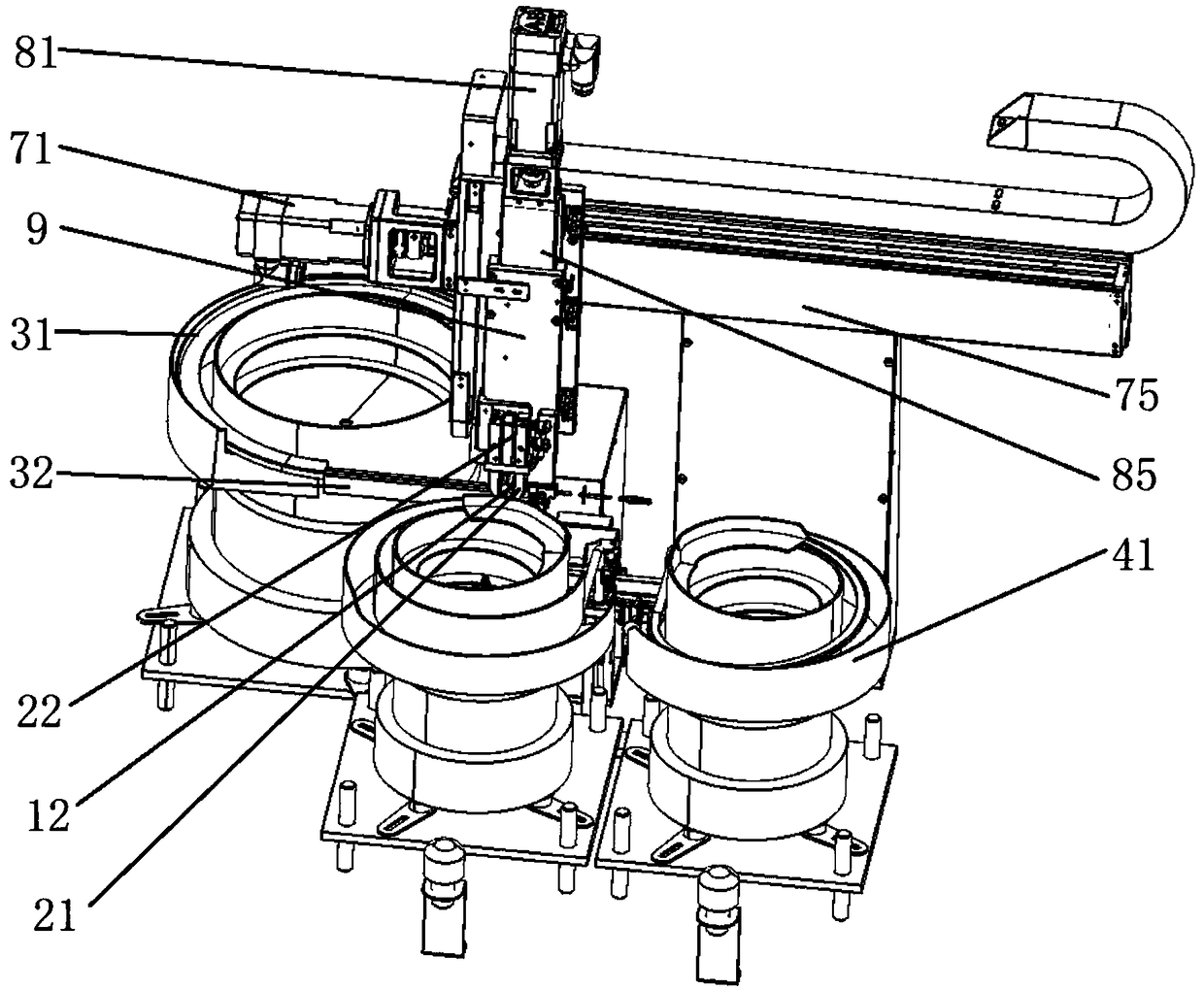

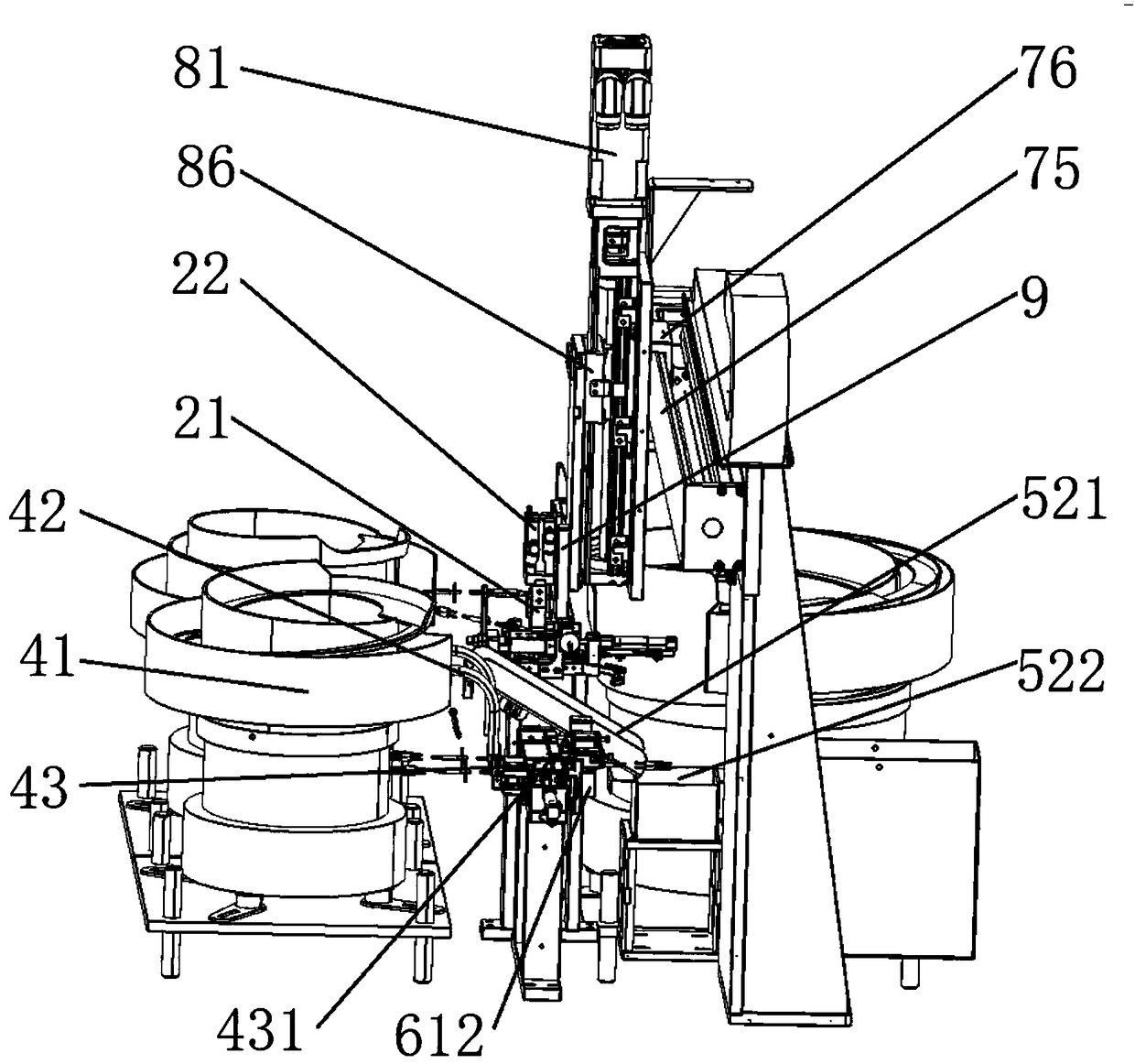

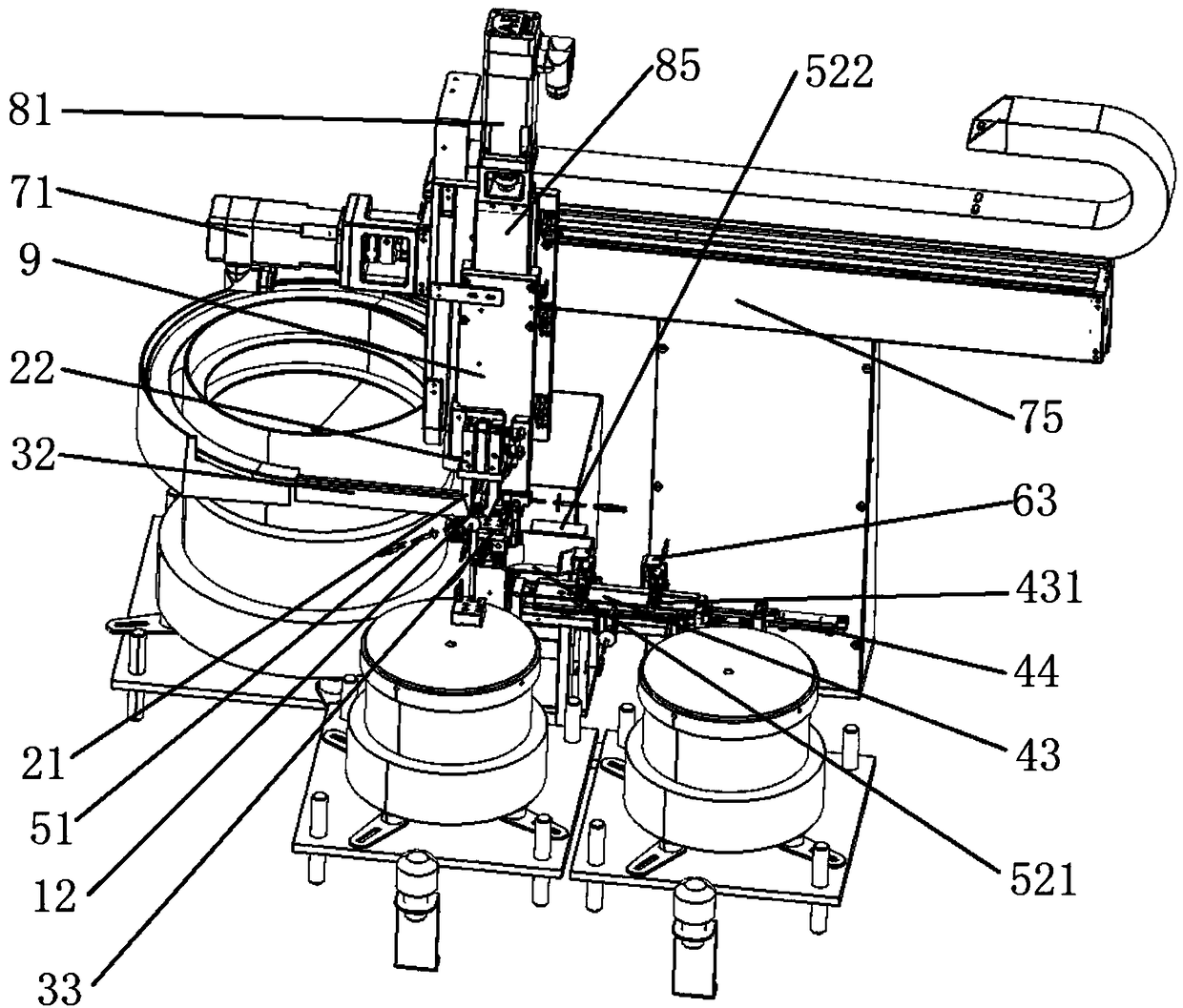

[0062] This embodiment provides an automatic assembly device for assembly components, which absorbs and installs the second assembled part on the first assembled part, and installs the assembled part composed of the first assembled part and the second assembled part to the workpiece superior. The automatic assembly device for assembly components in this embodiment includes a material distributing mechanism, an assembling mechanism, a moving mechanism and a material retrieving mechanism. Among them, the material distribution mechanism regularly outputs the first assembled part and the second assembled part respectively; the assembly mechanism assembles the first assembled part and the second assembled part on the workpiece; the moving mechanism is connected with the assembly mechanism and drives the assembly mechanism Perform assembly motion.

[0063] The material fetching mechanism in this embodiment includes a base block 9 , a clamping assembly disposed on the base block 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com