Forming machining knife

A forming processing and cutting tool technology, which is applied in the direction of manufacturing tools, metal processing equipment, and cutting tools for lathes, etc., can solve the problems of inability to achieve high-efficiency and high-precision processing, achieve good cutting stability, and reduce process difficulty , Improve the effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

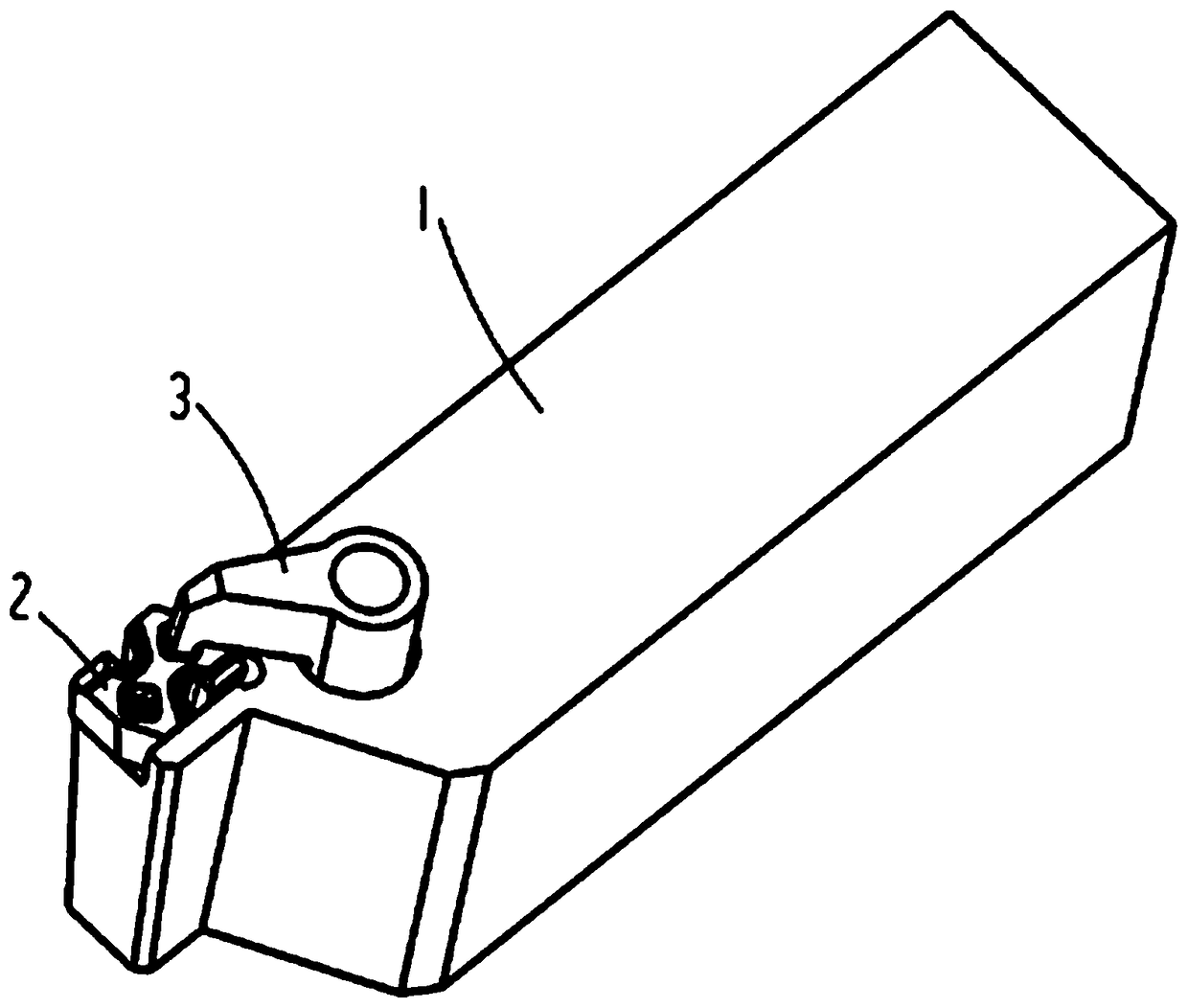

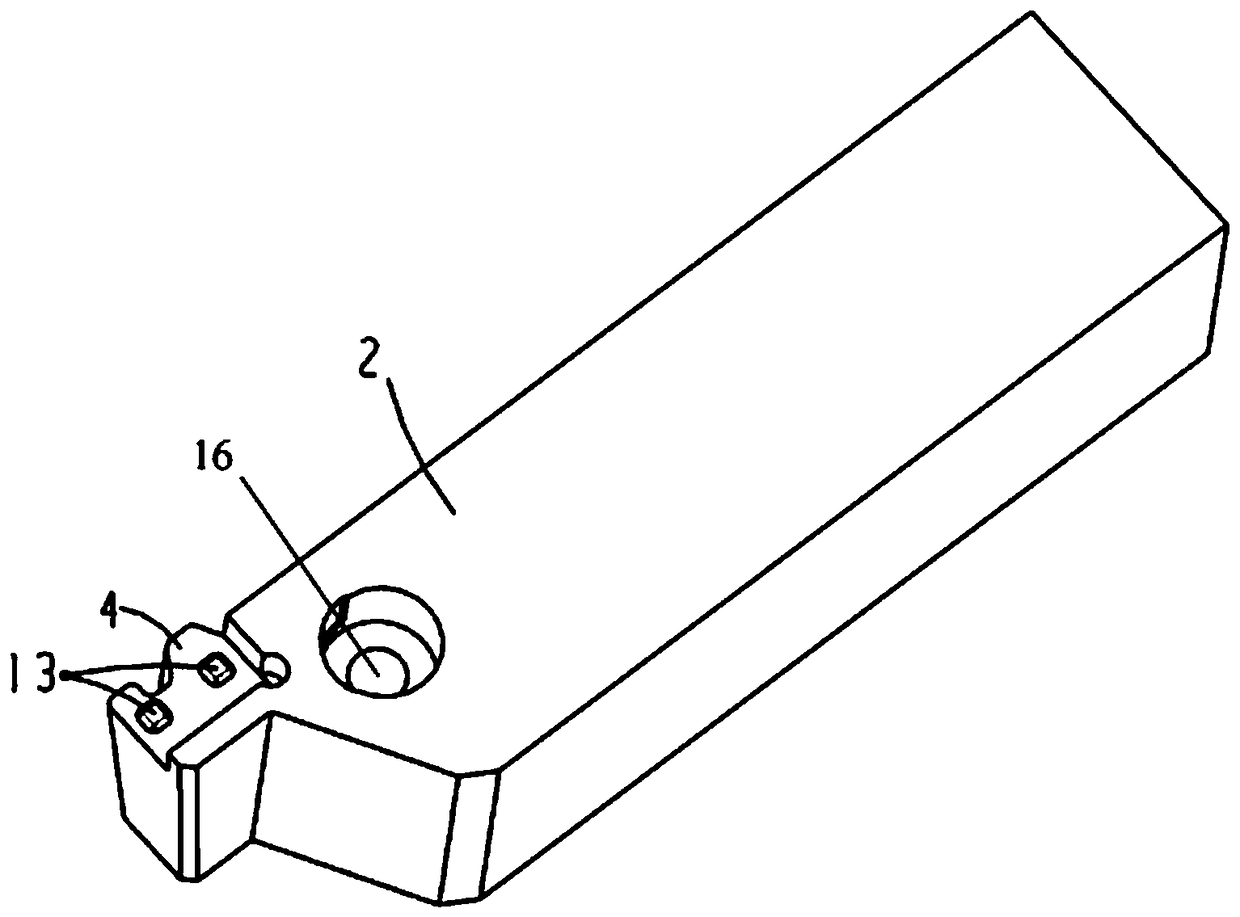

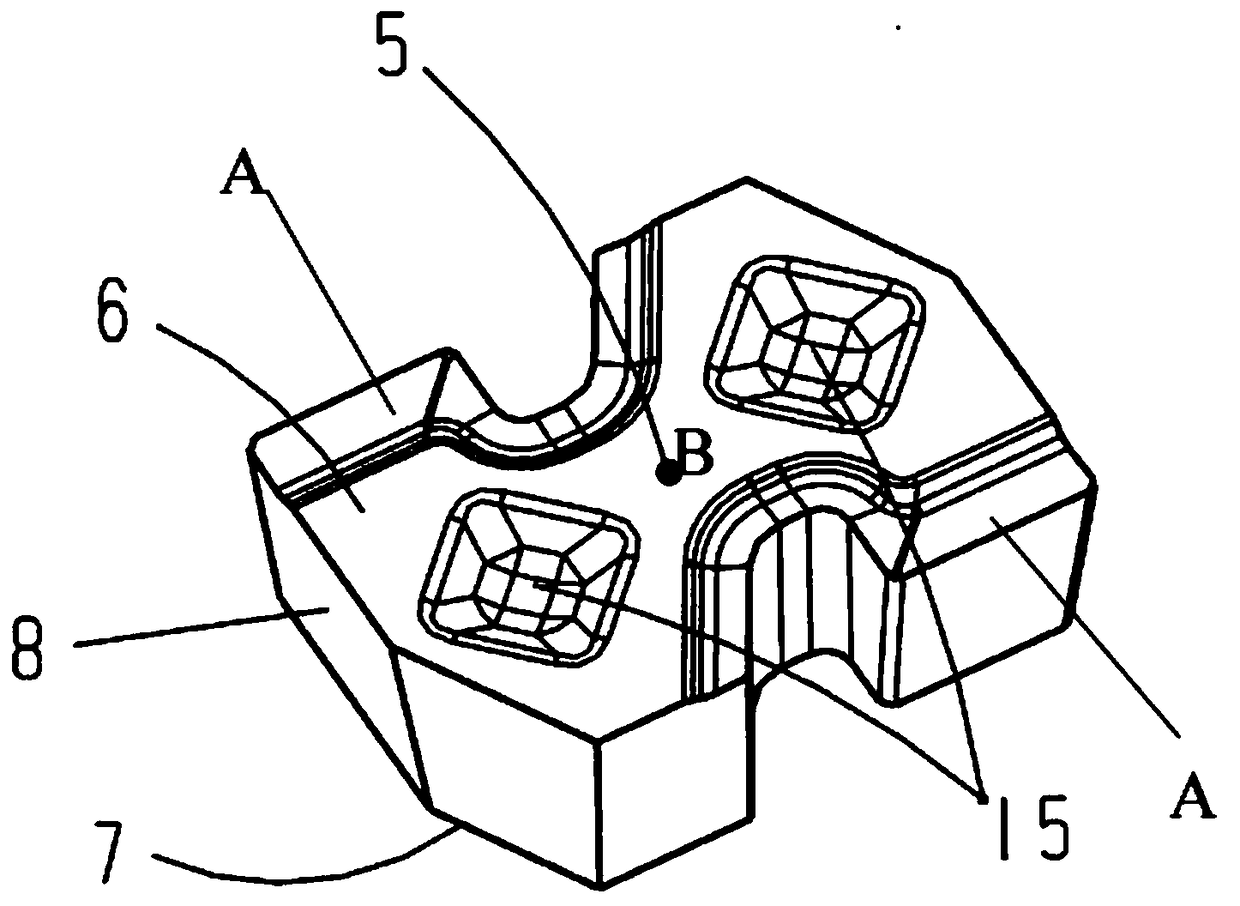

[0034] Provide a forming tool, such as figure 1 As shown, a tool for forming processing includes a tool bar 1 and an indexable cemented carbide blade 2. The indexable cemented carbide blade 2 includes a blade body 5, and the blade body 5 is a polygonal body including an upper end surface 6, the lower end surface 7, and a plurality of planar side surfaces and a plurality of arc-shaped side surfaces 8; the upper end surface 6 of the blade body 5 is provided with two cutting units A centered on the center point B of the blade, and the upper end surface is provided with the above The center point of the circular arc edge 97 of the lower cutting unit A connects with the two grooves 15 whose axis of symmetry is CC; the lower end surface is provided with two grooves 14 centered on the center point B of the blade. In the first embodiment, the shapes of the grooves on the upper end surface and the lower end surface are both square grooves.

[0035] The chip unit A includes a cutting edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com