An environmentally friendly rotary disc automatic spraying machine

A technology of automatic spraying and rotary disk, which is applied in the direction of spraying booths and spraying devices, which can solve the problems of low work efficiency, incomplete spraying, and inability to get spraying, etc., and achieve the effect of improving work efficiency and strong continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

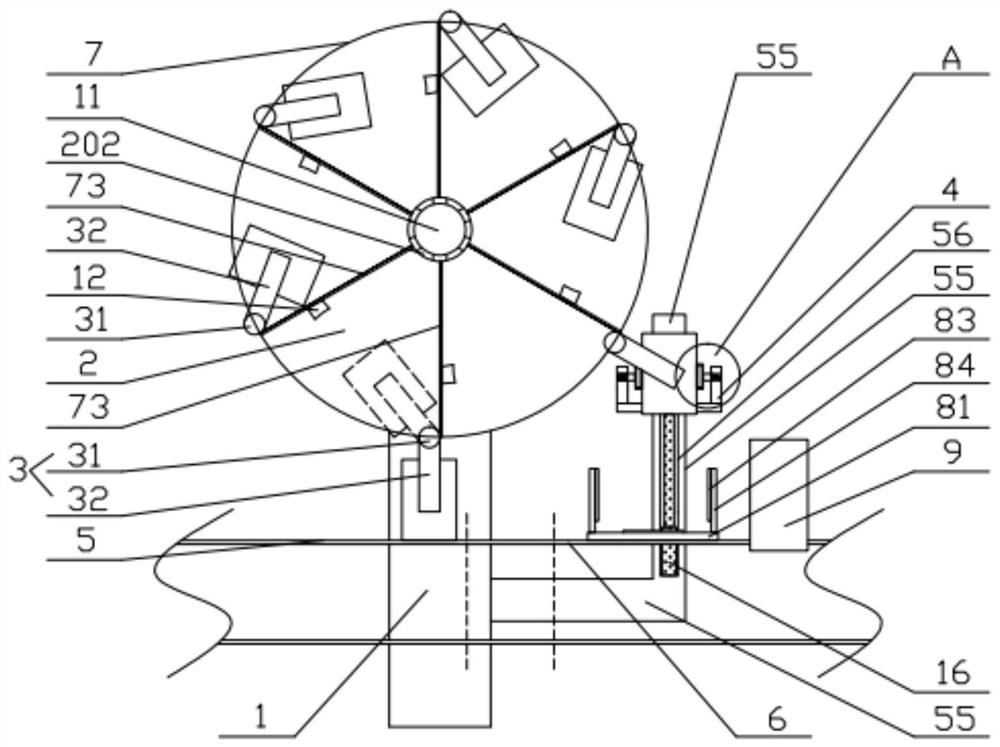

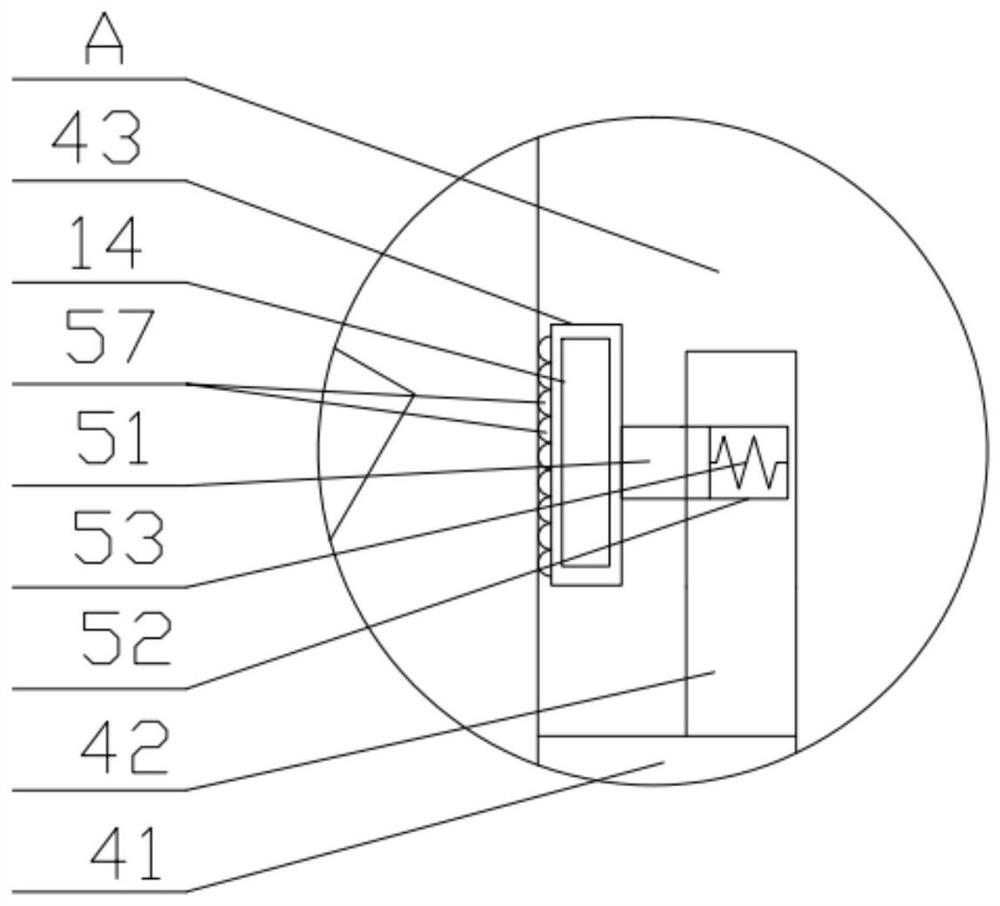

[0033] Such as figure 1 The shown a kind of environment-friendly rotating disk type automatic spraying machine comprises frame 1, material conveying line, spraying bin 2, retrieving manipulator 3, unloading manipulator 4 and suction dust channel 20, and described material conveying line includes feeding transmission Section 5 and unloading conveying section 6, described spraying machine also comprises vertical drum 7 standing vertically at the end of feeding conveying section 5, the head end of described unloading conveying section 6 is positioned at the side below rotating drum 7, and described unloading The manipulator 4 is located at the head end side of the unloading transmission section 6, the material positioning parts 8 are arranged at equal intervals on the unloading transmission section 6, and the spraying bin 2 9 is arranged in the area where the unloading transmission section 6 is located;

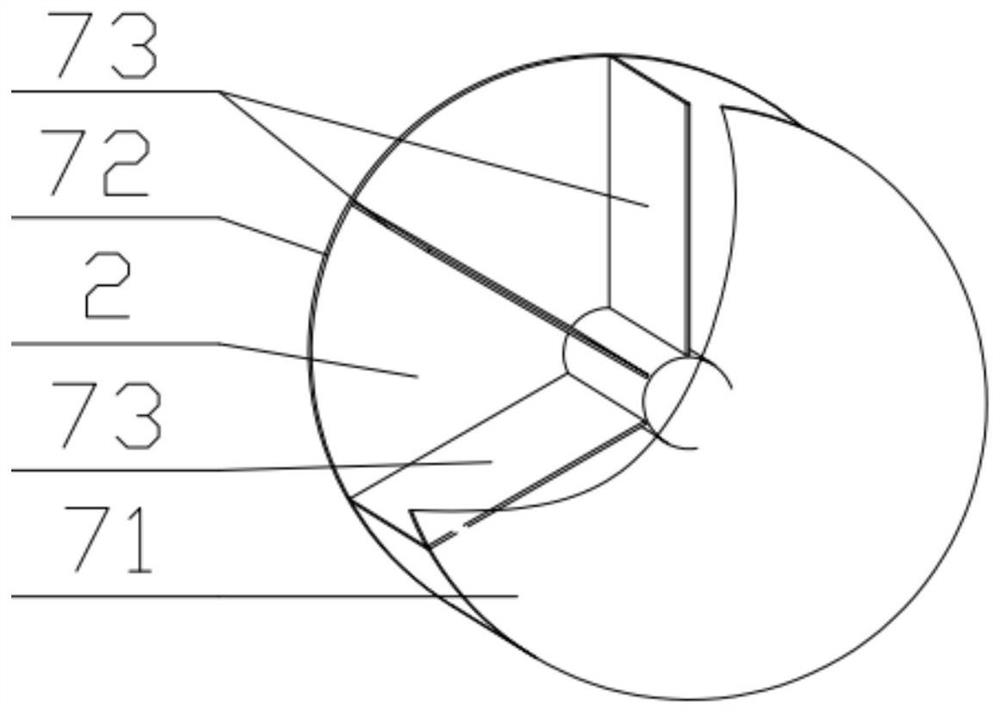

[0034] The center of the drum 7 is provided with a central shaft 11 mounted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com