Method and device for measuring microstructure morphology based on spectral modulation depth coding

A technology of depth coding and shape measurement, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of weak anti-interference ability, long measurement time, complex structure, etc., to reduce measurement errors, suppress measurement errors, The effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

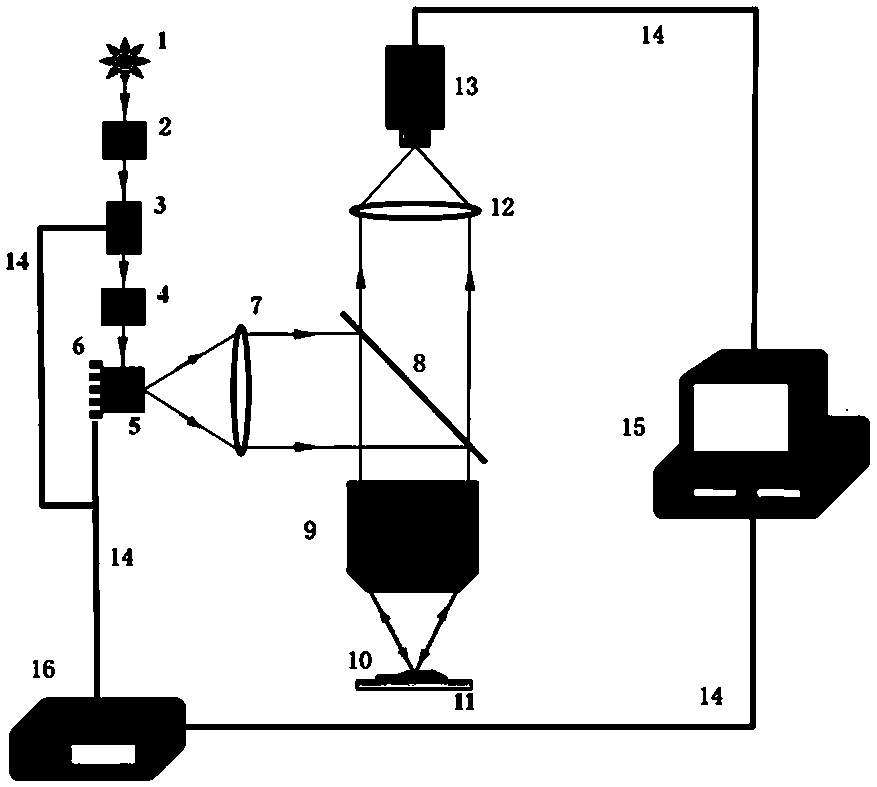

[0027] See attached figure 1, which is a structural schematic diagram of the microstructure topography measurement device based on spectral modulation degree depth coding provided in this embodiment. The measurement device consists of a wide-spectrum light source 1, a beam coupler 2, a spectral modulation gate 3, a uniform light coupler 4, a beam deflection coupler 5, a spatial light modulator 6, a collimating beam expander lens 7, and a beam splitter 8. Axial non-achromatic microscope objective lens 9, stage 11, imaging lens 12, color camera 13, data transmission control line 14, computer 15, and controller 16.

[0028] The polychromatic light emitted by the wide-spectrum light source 1 is evenly incident on the spectral modulation gate 3 through the beam coupler 2, and the spectral modulation gate 3 sequentially outputs monochromatic light of a specific wavelength within the spectral range for measurement, and passes through the uniform light coupler 4 and the beam deflecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com