Resistance reducing agent for coiled tubing and preparation method and application

A technology of drag reducing agent and tubing, which is applied in the field of drag reducing agent and preparation for coiled tubing, which can solve the problems of low drag reducing rate and achieve the effects of reduced frictional resistance, low corrosion and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

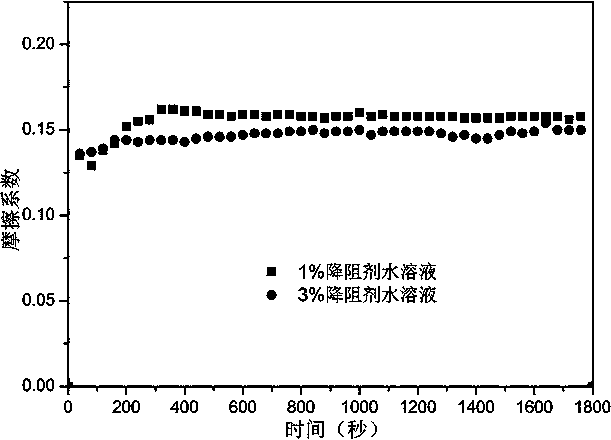

Image

Examples

Embodiment 1

[0025] This embodiment provides a drag reducing agent for coiled tubing, which is composed of the following substances in weight percentage: base oil 45-60%, anionic surfactant 14-18%, nonionic surfactant 15-20%, corrosion inhibitor Agent 5-8%, the balance is water.

[0026] The drag-reducing agent for coiled tubing provided by the present invention is used in combination with anionic surfactant and non-ionic surfactant to emulsify the base oil into small droplets and disperse them in the aqueous solution. The base oil plays the role of lubricating and reducing drag. The addition of corrosion inhibitor is used to reduce the corrosion effect of the solution on the coiled tubing.

Embodiment 2

[0028] On the basis of Example 1, this example provides a drag reducing agent for coiled tubing, which consists of the following substances in weight percent: 50% of base oil, 14% of anionic surfactant, 20% of nonionic surfactant, Corrosion inhibitor 6%, the balance is water.

[0029] Preparation:

[0030] Mix 50wt.% base oil 60N, 14wt.% sodium petroleum sulfonate, 10wt.% fatty alcohol polyoxyethylene ether and 10wt.% oleic acid diethanolamide, stir and heat to 65°C, then add 3wt.% Morpholine and 3wt.% diethanolamine, add the balance of water to make the sum of the mass percentages of each component 100%, continue to stir for 30min, and obtain a brown-yellow transparent oily drag reducer after cooling.

[0031] In this example, the base oil is 60N base oil; the anionic surfactant is sodium petroleum sulfonate; the nonionic surfactant is a compound of oleic acid diethanolamide and fatty alcohol polyoxyethylene ether (polymerization degree 10-20). Compounds, wherein, based on ...

Embodiment 3

[0033] On the basis of Example 1, this example provides a drag reducing agent for coiled tubing, which consists of the following substances in weight percentage: 55% of base oil, 16% of anionic surfactant, 18% of nonionic surfactant, Corrosion inhibitor 6%, the balance is water.

[0034] Preparation:

[0035] Mix 55wt.% base oil 60N, 8wt.% sodium petroleum sulfonate, 8wt.% sodium dodecylbenzenesulfonate, 8wt.% fatty alcohol polyoxyethylene ether and 10wt.% oleic acid diethanolamide Stir and heat to 70°C, then add 4wt.% morpholine and 2wt.% diethanolamine, add the rest of water to make the sum of the mass percentages of each component 100%, continue stirring for 30min, and obtain a brown-yellow transparent oily drag reducer after cooling .

[0036] In this example, the base oil is 60N base oil; the anionic surfactant is a compound of sodium petroleum sulfonate and sodium lauryl sulfate, based on the mass percentage of drag reducing agent, sodium petroleum sulfonate is 8% , s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com