Vehicle clutch control mechanism and protection method based on voice coil motor drive

A technology of clutch control and voice coil motor, which is applied in the field of automobile transmission, can solve problems such as disengagement or combination of clutch and clutch, high requirements for personnel, and limited life of electric air compressors, etc., and achieves simple structure and small space occupation , to avoid the effect of breaking down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

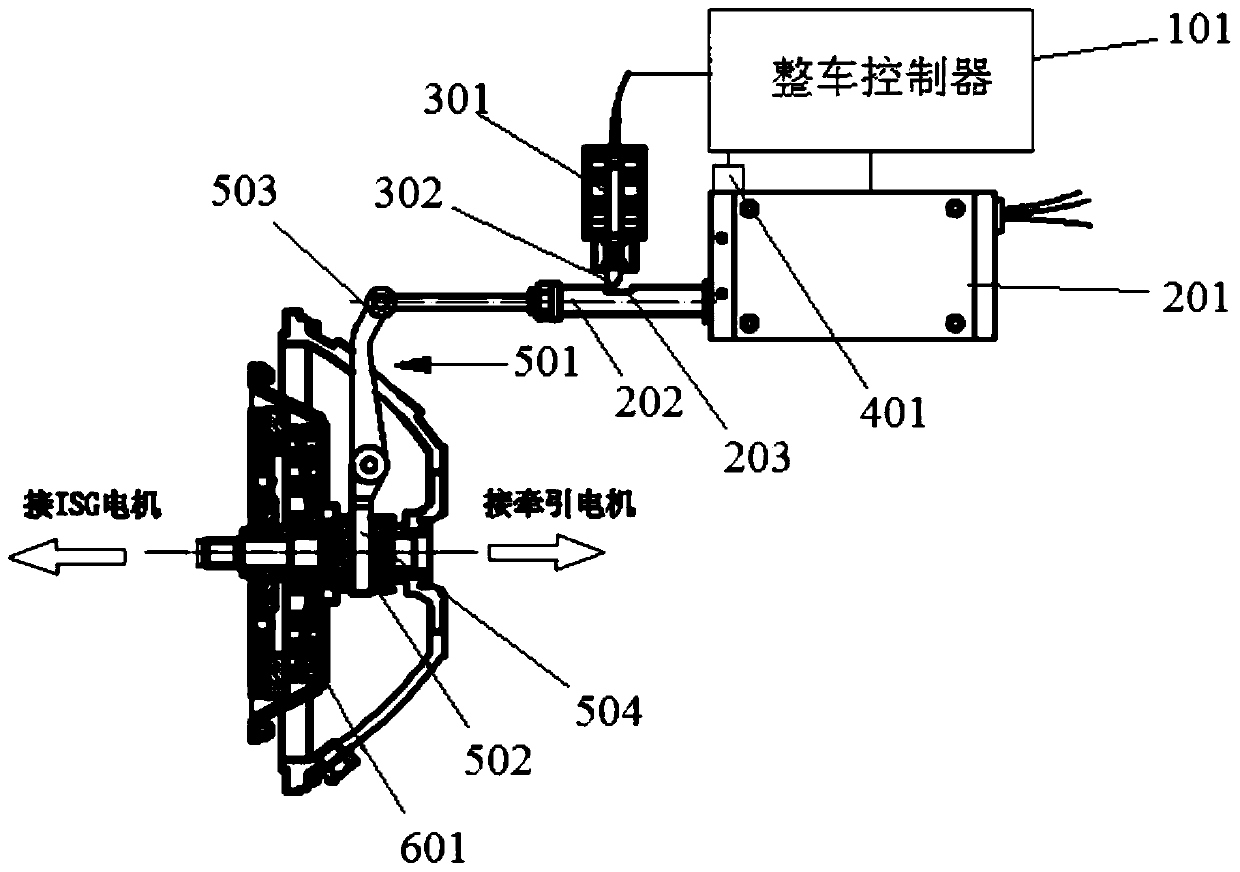

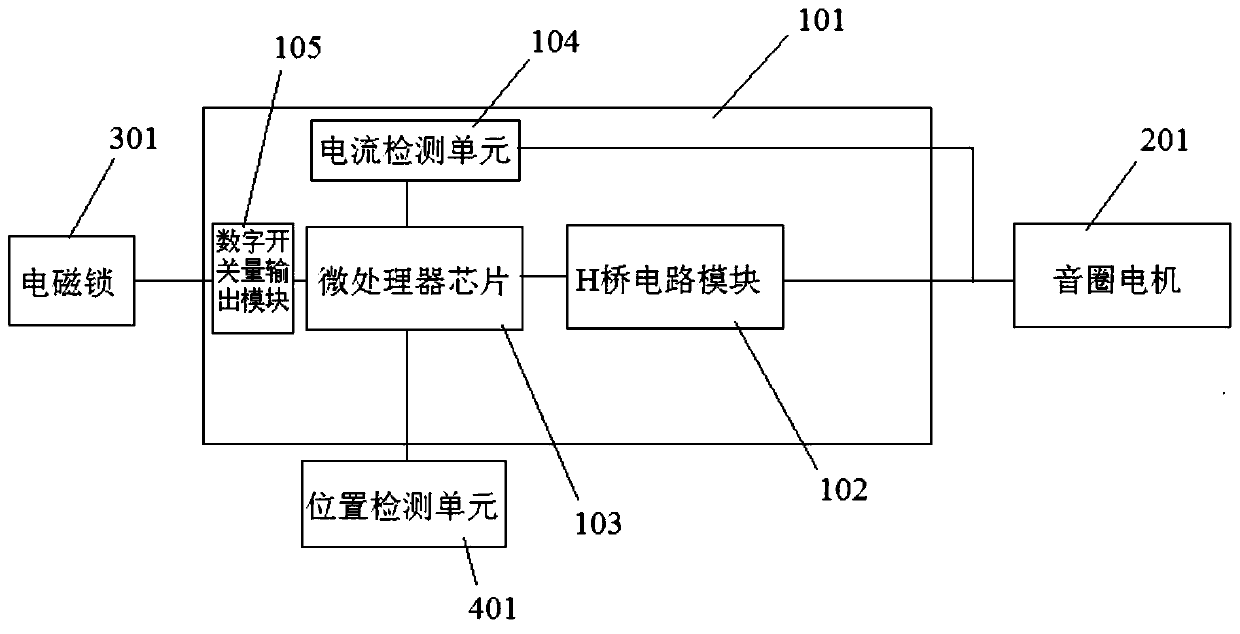

[0032] Such as figure 1 The vehicle clutch control mechanism based on the voice coil motor is shown, such as Figure 1~3 As shown, it includes a vehicle controller 101, a voice coil motor 201, an electromagnetic lock 301, a rocker type shift fork 501 and a release bearing 502 of a clutch 601 (diaphragm spring clutch), wherein the driving current of the vehicle controller 101 The output end is connected to the drive signal input end of the voice coil motor 201, and the vehicle controller 101 is connected to the control signal input end of the electromagnetic lock 301 through the digital switch output module 105. The push rod 202 of the voice coil motor 201 is provided with a groove 203, the lock head 302 of the electromagnetic lock 301 matches the groove 203 on the push rod 202, the lock head 302 is a one-way tapered structure, and the end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com