Mining motor fault early warning system

A technology of fault warning and coal mine motor, which is applied in safety, intelligent control system, underground belt drive in coal mine industry, and high-efficiency fields. Reduce downtime or avoid the expansion of accidents and safety accidents, prolong the service life and save the effect of manual maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

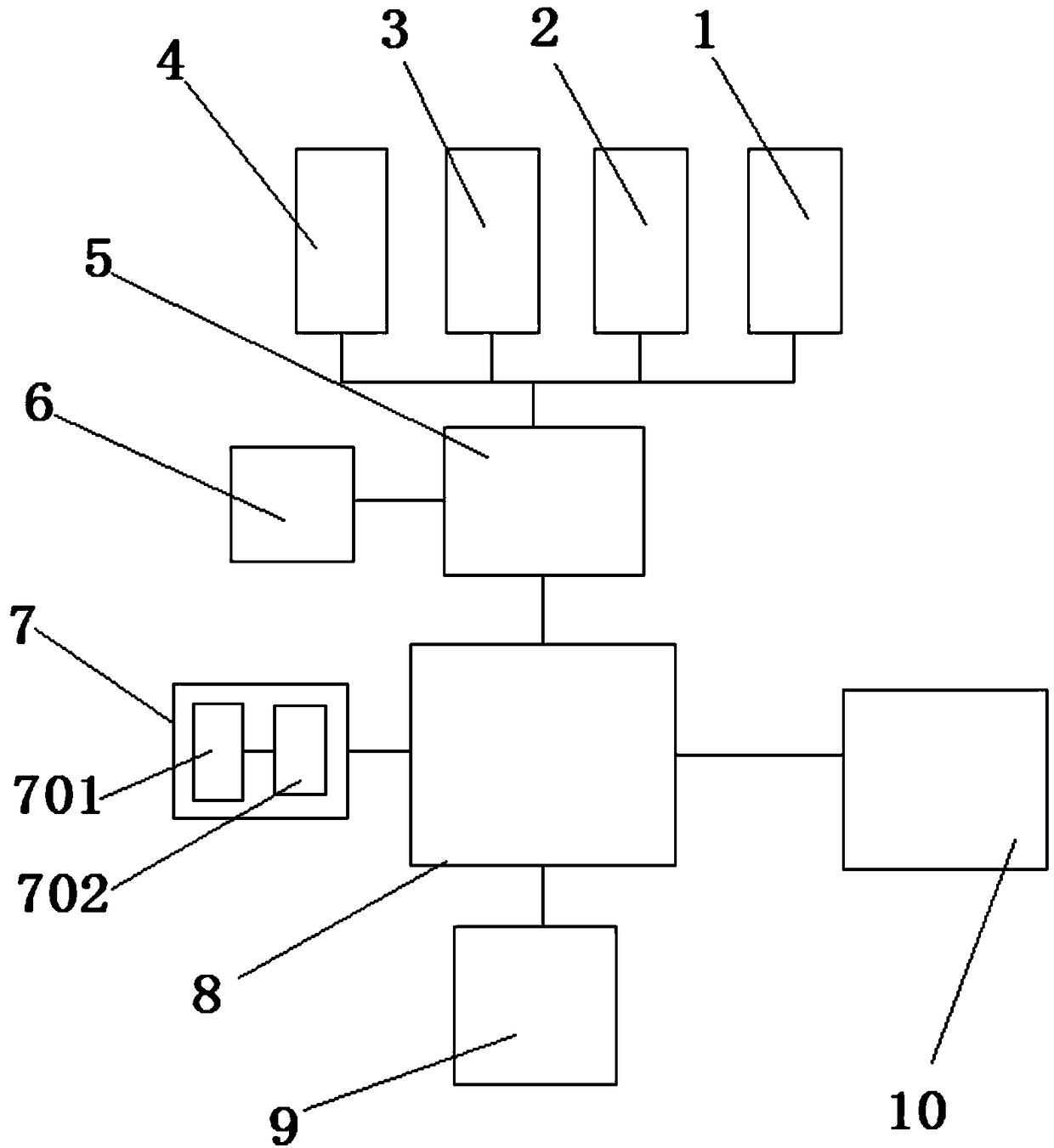

[0021] This embodiment provides a coal mine motor fault early warning system, characterized in that: the coal mine motor fault early warning system includes a vibration sensor 1, a temperature sensor 2, a current sensor 3, a voltage sensor 4, a data collector 5, and a touch screen 6 , remote diagnosis system 7, industrial computer 8, network service station 9, workstation 10;

[0022] Wherein: vibration sensor 1, temperature sensor 2, current sensor 3 and voltage sensor 4 are respectively connected with data collector 5, touch screen 6 is connected with data collector 5; data collector 5 is connected with industrial computer 8, and industrial computer 8 is connected with remote The diagnosis system 7, the network service station 9 and the workstation 10 are connected.

[0023] The data collector 5 is an M4 micro-power consumption data collector.

[0024] The remote diagnosis system 7 includes a remote diagnosis workstation 701 and a remote diagnosis server 702 .

[0025] The...

Embodiment 2

[0030] This embodiment provides a coal mine motor fault early warning system, characterized in that: the coal mine motor fault early warning system includes a vibration sensor 1, a temperature sensor 2, a current sensor 3, a voltage sensor 4, a data collector 5, and a touch screen 6 , remote diagnosis system 7, industrial computer 8, network service station 9, workstation 10;

[0031] Wherein: vibration sensor 1, temperature sensor 2, current sensor 3 and voltage sensor 4 are respectively connected with data collector 5, touch screen 6 is connected with data collector 5; data collector 5 is connected with industrial computer 8, and industrial computer 8 is connected with remote The diagnosis system 7, the network service station 9 and the workstation 10 are connected.

[0032] The industrial computer 8 is respectively connected with the remote diagnosis system 7, the network service station 9 and the workstation 10 through Ethernet.

[0033] Coal mine motor fault warning syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com