Method for reaming by explosion of detonating cord under well

A detonating cord and hole reamer technology, applied in drilling equipment and methods, blasting, drilling equipment and other directions, can solve the problems of small chip return channel, easy occurrence of pump stagnation, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

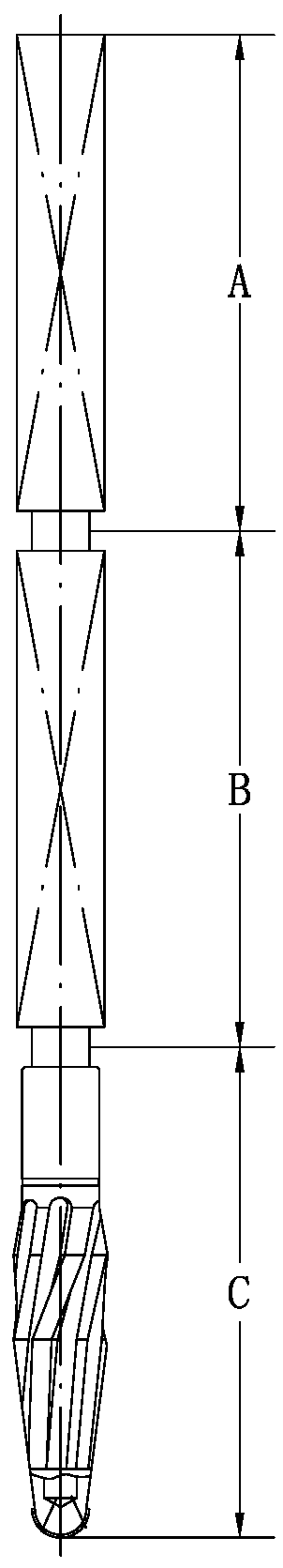

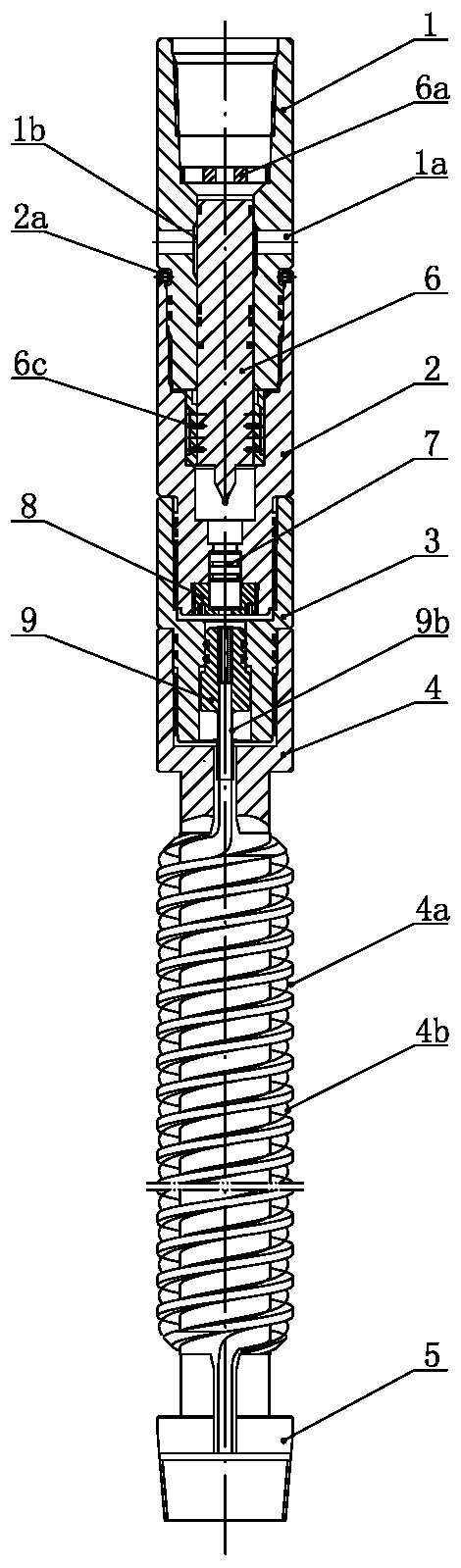

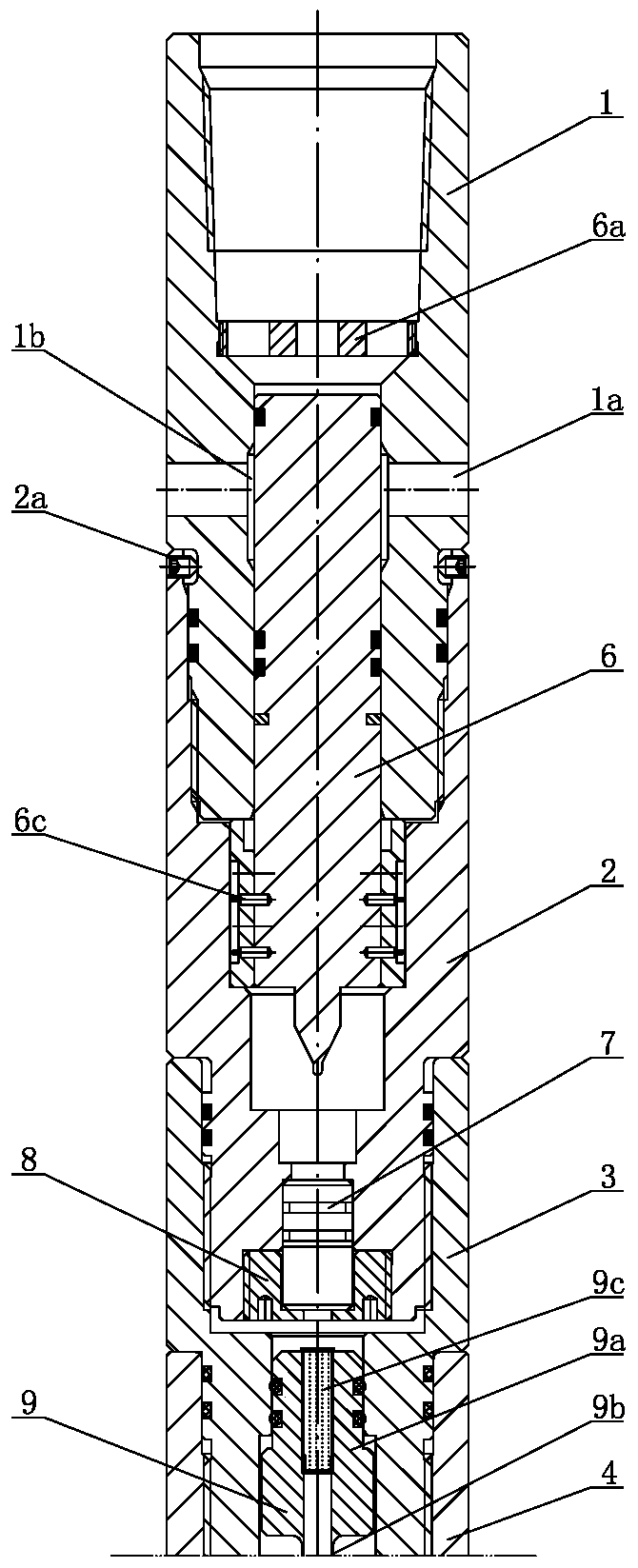

[0035] like figure 1 As shown, the downhole detonating cord explosion reaming method of the present invention comprises the following steps in turn: (1) installing a pilot reamer C at the lowermost end of the drill string; (2) screwing the explosive reaming above the pilot reamer C (3) The variable-diameter reamer A is screwed on the top of the explosive reamer B; (4) The upper end of the variable-diameter reamer A is connected to the drill string above; Down, the drill string goes down while rotating, and at the same time, the pilot reamer C can remove the sundries attached to the well wall; The drill string stops descending and stops rotating; (7) Turn on the mud pump and pressurize it to the set pressure for detonation to detonate the detonation index of the explosive reamer B, and the shock wave generated by the explosion acts on the rocks on the wellbore wall, resulting in formation The rock is crushed and broken to achieve reaming; (8) Turn the mud pump to the construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com