Preparation method of graphene-toughened-resin-based carbon fiber composite

A technology for toughening resins and composite materials, applied in the field of composite materials, can solve the problems of easy agglomeration, affecting the performance of composite materials, uneven dispersion of graphene, etc., to improve strength and toughness, improve dispersion, and improve conjugation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Please join the attached figure 1 , 2, 3, 4, a preparation method of graphene toughened resin-based carbon fiber composite material, first graphene and low-viscosity reactive dispersant are ultrasonically dispersed to prepare graphene dispersion, and then the dispersion is mixed with resin Mix and prepare a certain concentration of toughening resin, and then adopt the preparation process of carbon fiber prepreg, prepare graphene toughened carbon fiber prepreg through continuous impregnation and drying, and prepare the required carbon fiber prepreg through laying, molding and curing. Graphene toughened resin-based carbon fiber composite material; its specific steps are as follows:

[0041] Step 1: Preparation of pre-product

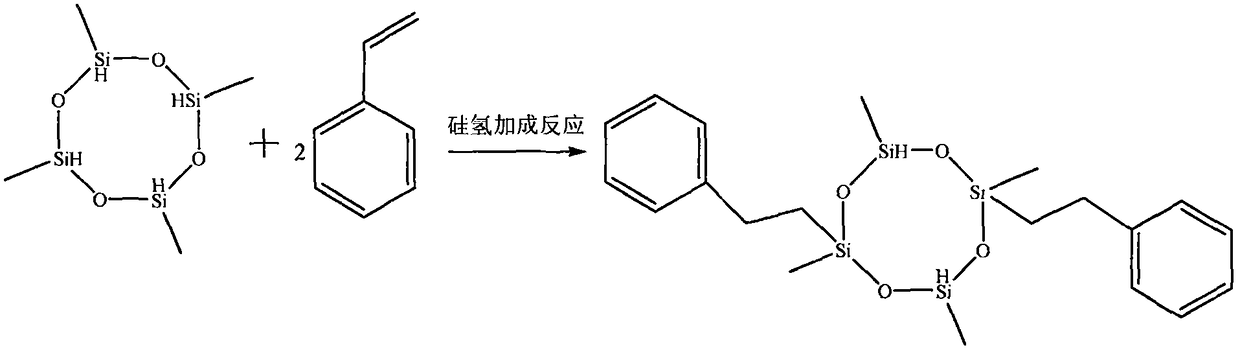

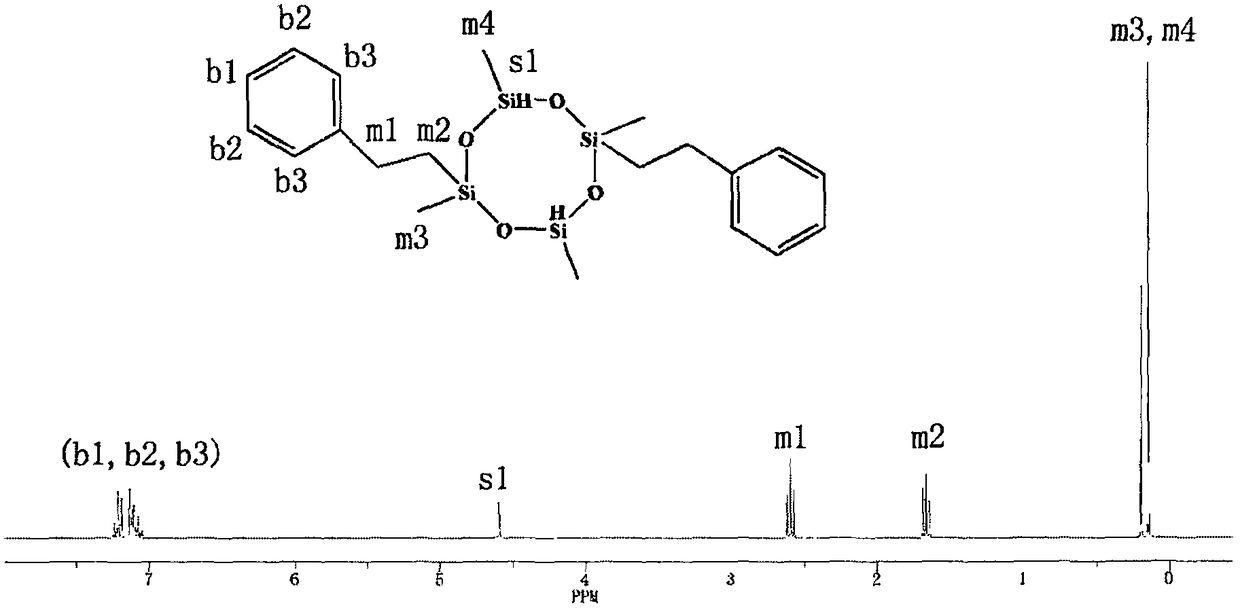

[0042] In a nitrogen atmosphere, take tetramethylcyclotetrasiloxane and styrene as raw materials, control the molar ratio of tetramethylcyclotetrasiloxane and styrene to be 1: 2.15, and use the isopropanol solution of chloroplatinic acid as Cataly...

Embodiment 2

[0070] A method for preparing a graphene-toughened resin-based carbon fiber composite material. First, graphene and a low-viscosity reactive dispersant are ultrasonically dispersed to prepare a graphene dispersion, and then the dispersion is mixed with a resin to prepare a certain concentration. Toughening resin, and then using the preparation process of carbon fiber prepreg, the graphene toughened carbon fiber prepreg is prepared by continuous impregnation and drying, and the required graphene toughened resin based carbon fiber is prepared by laying, molding and curing Composite material; its specific steps are as follows:

[0071] Step 1: Preparation of pre-product

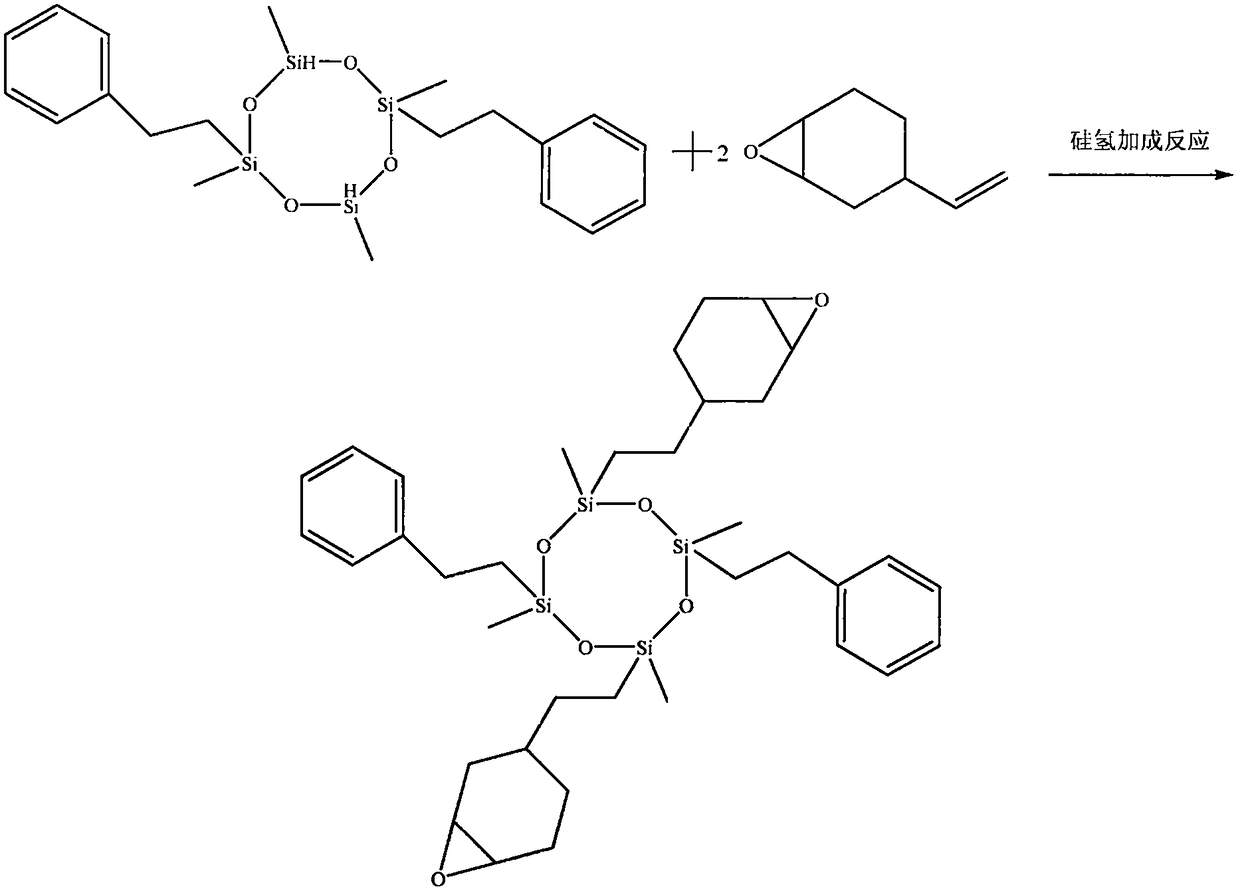

[0072] In a nitrogen atmosphere, take tetramethylcyclotetrasiloxane and styrene as raw materials, control the molar ratio of tetramethylcyclotetrasiloxane and styrene to be 1: 2.20, and use the isopropanol solution of chloroplatinic acid as Catalyst: Mix the catalyst and styrene to prepare styrene catalytic liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com