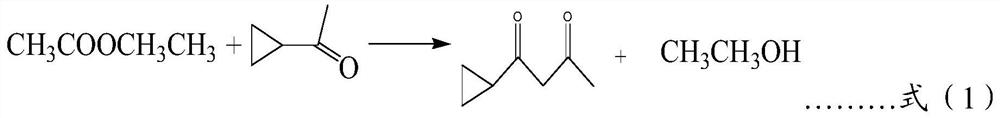

A kind of cyclopropionyl acetone and its synthetic method

A technology of cyclopropionyl acetone and its synthesis method, which is applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of carbonyl compounds by condensation, etc., and can solve the problems of low reaction yield, high recovery energy consumption, and large energy consumption. , to achieve the effects of saving raw material costs, low environmental requirements, and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A synthetic method for cyclopropionyl acetone, comprising the following steps:

[0032] Step 1, add 500kg of 98% absolute ethanol in the reactor, stir with the rotating speed of 95 rpm at room temperature, add 46kg sodium metal in batches while stirring (add sodium metal once every 10 minutes, divide 9 times Adding), in the process of adding sodium metal, the temperature was controlled at 64°C by opening the jacket to cool down the water, and then the temperature was raised to 78°C for 1 hour to completely dissolve the sodium metal, and the ethanol was recovered under normal pressure at 78°C for 2 hours. After recovering 350kg of ethanol, a mixed solution of sodium ethylate and ethanol was obtained.

[0033] Step 2, add 170kg of cyclopropyl methyl ketone to the mixed solution, stir at 60°C at a speed of 95 rpm for 30 minutes, add 88kg of ethyl acetate, and reflux at 60°C for 1 hour. Slowly heat up to 78°C within 30 minutes and recover 150kg of ethanol under normal pres...

Embodiment 2

[0038] A synthetic method for cyclopropionyl acetone, comprising the following steps:

[0039] Step 1, add 480kg of 98% absolute ethanol in the reactor, stir with the rotating speed of 95 revs / min at room temperature, add 46kg metallic sodium in batches while stirring (add 4.5kg of metallic sodium once every 10 minutes, divide 9 additions), during the process of adding sodium metal, the temperature was controlled at 65°C by opening the jacket to cool down the water, and then the temperature was raised to 80°C for 1.2 hours to completely dissolve the sodium metal, and 1.7 ethanol was recovered under normal pressure at 79°C Hour, after ethanol reclaims 350kg, get the mixed liquor of sodium ethylate and ethanol.

[0040] Step 2, add 180kg of cyclopropyl methyl ketone to the mixed solution, stir at a speed of 95 rpm at 55°C for 25 minutes, add 86kg of ethyl acetate, and reflux at 55°C for 1.2 hours. Slowly heat up to 79°C within 30 minutes and recover 150kg of ethanol under norma...

Embodiment 3

[0044] A synthetic method for cyclopropionyl acetone, comprising the following steps:

[0045] Step 1, add 520kg of 98% absolute ethanol in the reactor, stir with the rotating speed of 95 revs / min at room temperature, add 46kg metallic sodium in batches while stirring (add 5.5kg of metallic sodium once every 10 minutes, divide 9 additions), during the process of adding sodium metal, the temperature was controlled at 62°C by opening the jacket to cool down the water, and then the temperature was raised to 79°C for 1.5 hours to completely dissolve the sodium metal, and 1.5 ethanol was recovered under normal pressure at 80°C. Hour, after ethanol reclaims 350kg, get the mixed liquor of sodium ethylate and ethanol.

[0046] Step 2, add 160kg of cyclopropyl methyl ketone to the mixed solution, stir at 60°C at a speed of 95 rpm for 30 minutes, add 90kg of ethyl acetate, and reflux at 50°C for 1.5 hours. Slowly heat up to 80°C within 35 minutes and recover 150kg of ethanol under norm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com