Hydraulic direct-acting type steel pipe expanding head

A steel pipe diameter expansion, direct-acting technology, applied in the field of structural systems, hydraulic direct-action steel pipe expansion head, can solve the problems of high processing accuracy, lower mechanical efficiency of equipment, high use and maintenance costs, etc., to achieve easy maintenance, The effect of reducing equipment costs and maintenance costs and increasing overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

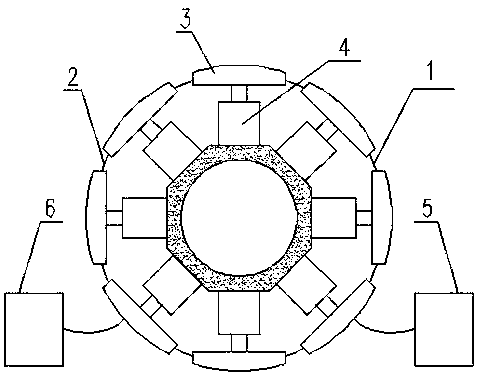

[0022] A hydraulic direct-acting steel pipe expansion head, which includes a diameter expansion head body 1, a hydraulic control system 5 and an electrical control system 6, the expansion head body 1 includes a diameter expansion head frame 2 and several expansion heads of the same specification. Diameter device, wherein the diameter expansion device is fixed on the outer wall of the frame 2 along the circumference of the diameter expansion head, and several diameter expansion devices are electrically connected with the hydraulic control system 5, and the hydraulic control system 5 is connected to the external power supply through the electrical control system 6. sexual connection.

[0023] The hydraulic direct-acting steel pipe expansion head is easy to implement and has strong practicability. It abandons the traditional cone and inclined plane structure and adopts several expansion devices of the same specification, which avoids the expensive processing of cones and inclined ...

Embodiment 2

[0025] Such as figure 1 , image 3 As shown, it is improved on the basis of Embodiment 1, and the diameter expanding device includes a straight-acting hydraulic cylinder 4 and an expanding die 3 fixedly connected with the direct-acting hydraulic cylinder 4 .

[0026] The cylinder part of the straight-acting hydraulic cylinder 4 is fixed on the outer wall of the expanding head frame 2 circumferentially, and one end face of the expanding die 3 is fixed to the end of the piston rod of the direct-acting hydraulic cylinder 4, and the expanding die The other end face of 3 is an arc surface.

[0027] When the several straight-acting hydraulic cylinders 4 are at the maximum stroke, the arc surface of each expanding die 3 is located on the arc of a concentric circle of the expanding head frame 2 .

[0028] The several direct-acting hydraulic cylinders 4 are electrically connected with the hydraulic control system 5 .

[0029] The expansion head body 1 includes the expansion head fra...

Embodiment 3

[0031] Such as image 3 , Figure 4 As shown, it is improved on the basis of Embodiment 1. The expander head frame 2 is a cylindrical structure, and the outer edges of the outer walls of the cylinder outer walls of the expander head frame 2 have retaining walls. The expander head frame 2 The outer wall of the cylinder between the retaining walls at both ends is fixed with a number of straight-acting hydraulic cylinders 4 at intervals in the circumferential direction, and the height of the outer edge of the retaining wall is greater than the arc surface height of the expanding die 3 in the non-working state, and smaller than the arc surface of the expanding die 3 in the working state high.

[0032] The cylinder of the expanding head frame 2 is integrally formed with the retaining walls located at the outer edges of both ends of the outer wall.

[0033] The expansion head frame 2 of the cylindrical structure has retaining walls on both ends of the outer wall of the cylinder. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com