Grass planting and sheep raising method under photovoltaic solar energy

A photovoltaic solar energy and solar panel technology, applied in the agricultural field, can solve the problems of unfavorable agricultural mechanization operation, unfavorable agricultural mechanization operation, and many columns in the greenhouse, so as to reduce manual labor operation, prevent grass lodging disease, and improve water and fertilizer conservation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1: Install monocrystalline silicon solar panels on the sunny side of the pasture with an inclination of 30°. The panels are fixed on the support frame and the height of the lowest point from the ground exceeds 2m, and the distance between any two panels is 4m;

[0035] Step 2: Set up fences on the periphery of the pasture, and build sheep houses and fermentation tanks in the center. The circuit systems in the pasture and sheep houses are connected to monocrystalline silicon solar panels, and the remaining electricity is integrated into the national grid;

[0036] Step 3: In April, apply base fertilizer at 150kg / mu, plow the soil 20cm deep, and dry it for 5 days;

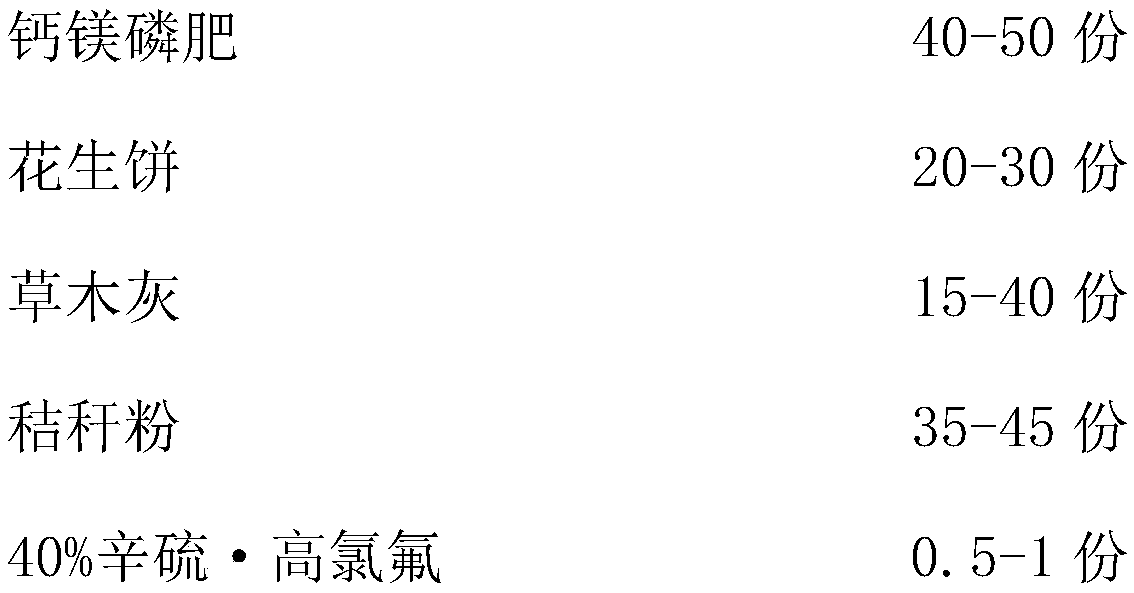

[0037] Wherein, the base fertilizer includes the following components in parts by weight:

[0038]

[0039]

[0040] Step 4: mix ryegrass seeds, tall fescue seeds, alfalfa seeds and milkvetch seeds according to the weight ratio of 1:0.5:0.8:0.3 to prepare mixed grass seeds, and place the mixed grass...

Embodiment 2

[0047] The operation is the same as in Example 1, wherein, step 1: the inclination angle is 45°, and the solar panel is a polysilicon solar panel, and the distance between the two panels is 5m; 6 days, the parts by weight of each component of the base fertilizer are 45 parts, 25 parts, 28 parts, 40 parts, 0.75 parts, and 1.1 parts; The pretreatment process of grass seeds: the water temperature and soaking time are respectively 45°C and 6h; 28°C, 88%, germination 1.5d, sowing density 5kg / mu, step 5: time for the first cut: 33 days after sowing, stubble height is 6cm, stocking time: after the first cut 25 days, stocking density and time are respectively 70 head / mu, 9h, and the parts by weight of each component of sheep feed are 40 parts, 50 parts, 18 parts, 45 parts, 17 parts, 30 parts, 9 parts, 6 parts; Step 7 : The stubble height is 4cm, and the silage fermentation days are 45 days; Step 8: The cultivation period is 7.5 months.

Embodiment 3

[0049] The operation is the same as in Example 1, wherein, step 1: the inclination angle is 60°, the solar cell panel is a multi-component solar cell, and the distance between the two panels is 6m; 7 days, the parts by weight of each component of the base fertilizer are 50 parts, 30 parts, 40 parts, 45 parts, 1 part, and 1.3 parts; The pretreatment process of grass seeds: the water temperature and soaking time are respectively 50°C and 8h; 30°C, 90% respectively, germination for 2 days, sowing density of 6kg / mu, step 5: first cutting time: 38 days after sowing, stubble height is 7cm, stocking time: 30 days after the first cutting Day, stocking density and time are respectively 90 head / mu, 10h, and the parts by weight of each component of sheep feed are 50 parts, 60 parts, 21 parts, 60 parts, 19 parts, 40 parts, 10 parts, 8 parts; Step 7: The stubble height is 5 cm, and the silage fermentation days are 65 days; step 8: cultivation is 8 months.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com