A Periodic Dielectric Filled Coaxial High Power Microwave Device

A high-power microwave and dielectric technology, applied to the circuit components of the time-of-flight electron tube, to achieve the effect of improving beam conversion efficiency and enhancing clustering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

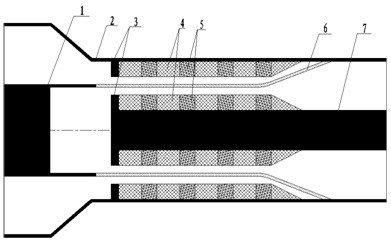

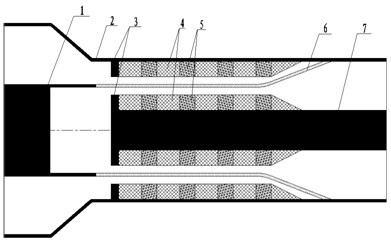

[0031]The cathode in the device is made of graphite material, which relies on the electric field force between the cathode and anode to generate a ring-shaped high-current electron beam. The inner diameter of the graphite cathode is 1.5cm and the outer diameter is 1.6cm. Under the guidance of the magnetic field, the annular high-current electron beam enters the coaxial dielectric cavity through the annular injection port for transmission. The guiding magnetic field strength of the electron beam is 0.8T, the voltage is 400kV, and the current is 2kA. The inner diameter of the metal outer cylinder is 2.6cm, and the inner wall of the metal outer cylinder and the coaxial inner conductor are periodically filled with two kinds of dielectrics with different dielectric coefficients. The structural parameters of the coaxial dielectric filled on the inner wall of the metal outer cylinder and the outer wall of the coaxial inner conductor are as follows: The arrangement is exactly the same....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com