Combined rotation system assembly online dynamic balance detection system and method

A detection system and balancing technology, applied in static/dynamic balance testing, measuring device, machine/structural component testing, etc., can solve problems such as unbalanced measurement, unbalance, etc. The effect of reducing the number of machine starts and stops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

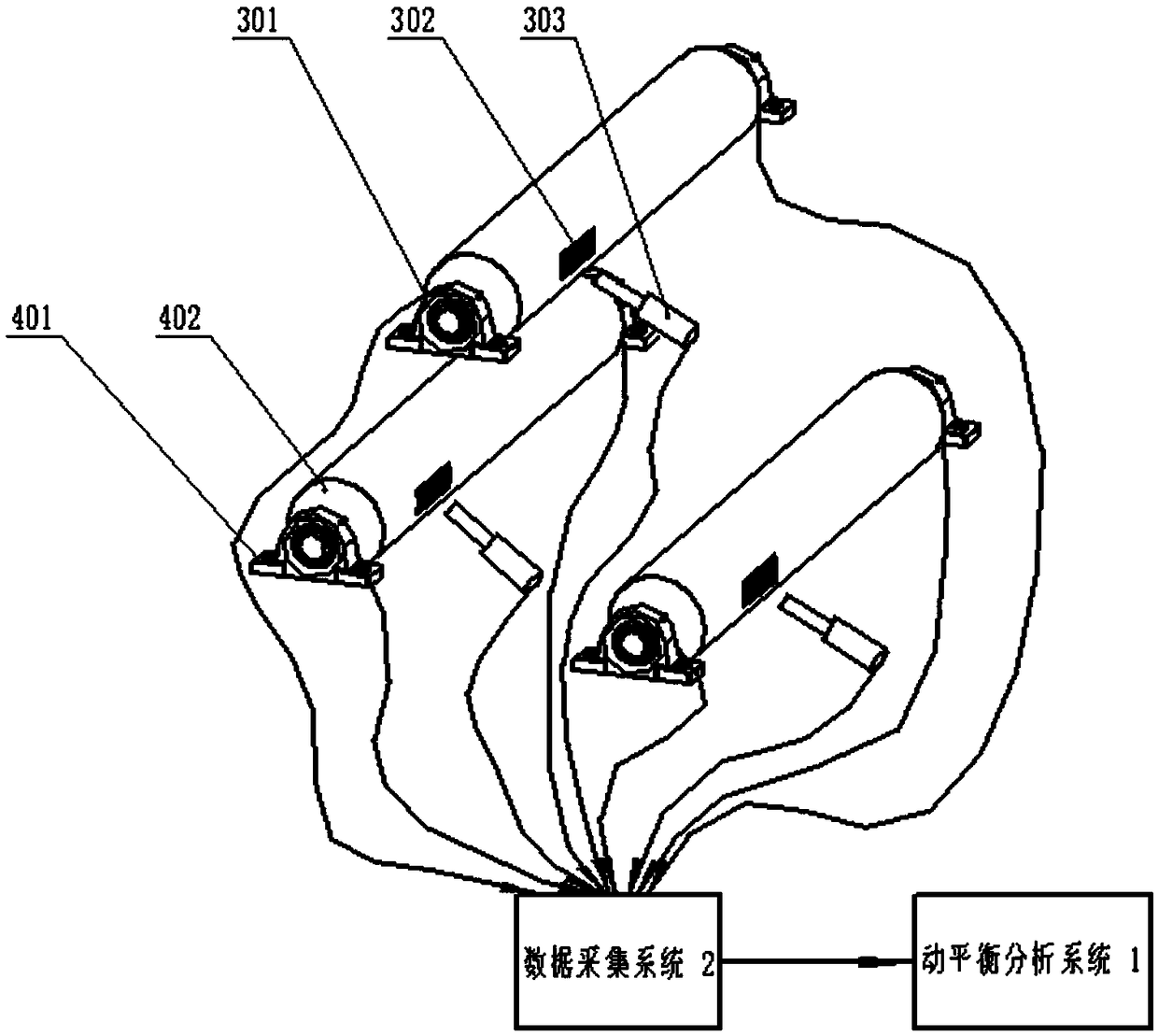

[0037] Such as figure 1As shown, the combined rotary system of the present invention is assembled with an online dynamic balance detection system, including a balance analysis system 1 , a data acquisition system 2 , a detection sensor 3 , and a combined rotary system 4 . The detection sensors include a vibration test sensor 301 , a reflective mark 302 , and a rotational speed test sensor 303 , and the combined rotary system includes a bearing seat 401 and a rotor 402 . The bearing seat 401 is connected with the rotor 402; the reflective mark 302 is pasted on the rotor 402; the rotational speed test sensor 303 is installed on the non-rotating part, and aligned with the reflective mark on the rotor, the distance is generally 30mm. The vibration test sensors 301 are instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com