Monitoring device and method for high-supported formwork template settlement

A technology of settlement monitoring and high-support formwork, applied in the direction of hydrostatic pressure and the like, can solve problems such as being easily affected by wind loads, internal formwork cannot be observed, and real-time monitoring cannot be realized, so as to eliminate potential safety hazards and prevent collapse and instability Accidents, the effect of ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

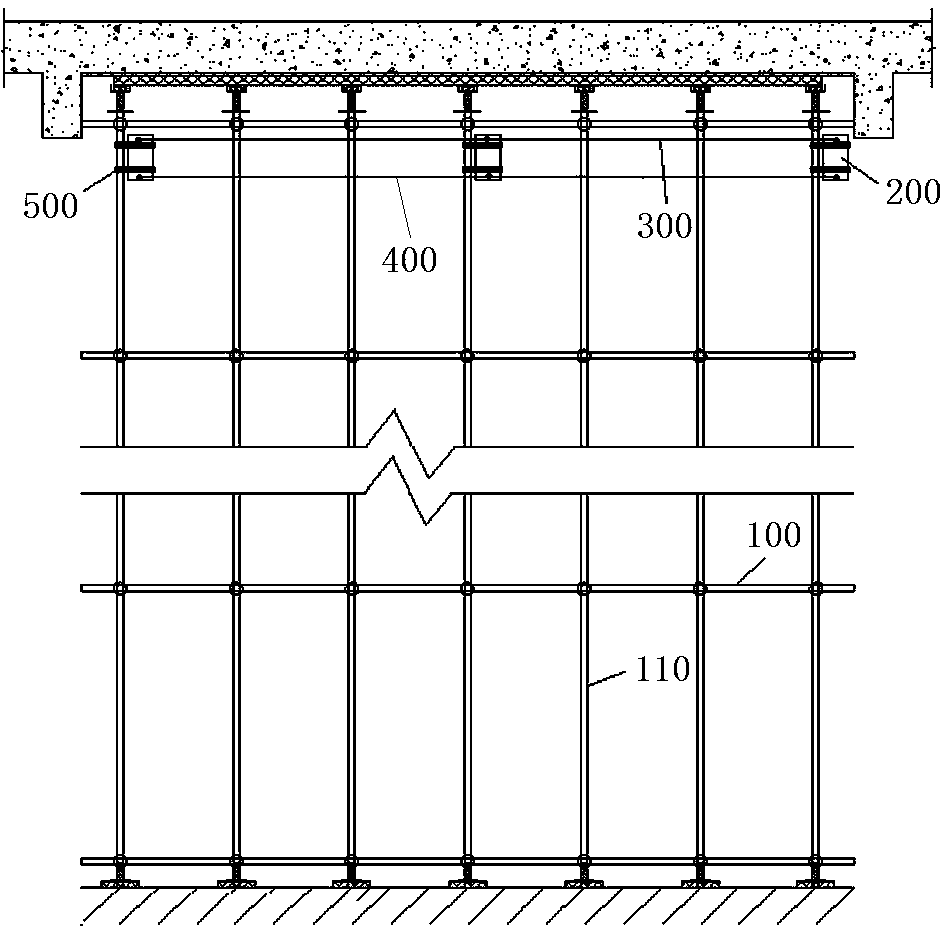

[0016] Embodiment one: if figure 1 , 4 As shown, a high formwork template settlement monitoring device includes a support frame 100 for supporting the formwork, and a fiber grating static level 200 (model LH-FBG-HL ), the fiber grating static levels are located at the same height at the upper end of the pole 110, and the fiber grating static levels at the same end of the pole are connected in series through the vent pipe and the liquid pipe, that is, all the fiber grating static levels located at the upper end of the pole are passed through The gas pipe 300 and the liquid pipe 400 are connected in series, and the fiber grating static level is connected with the fiber grating demodulator through an optical fiber, so that the liquid and gas inside each fiber grating static level can flow with each other, and the fiber grating static level after communication The liquid level in the level will always remain at the same level. When the vertical rod at the monitoring point settles...

Embodiment 2

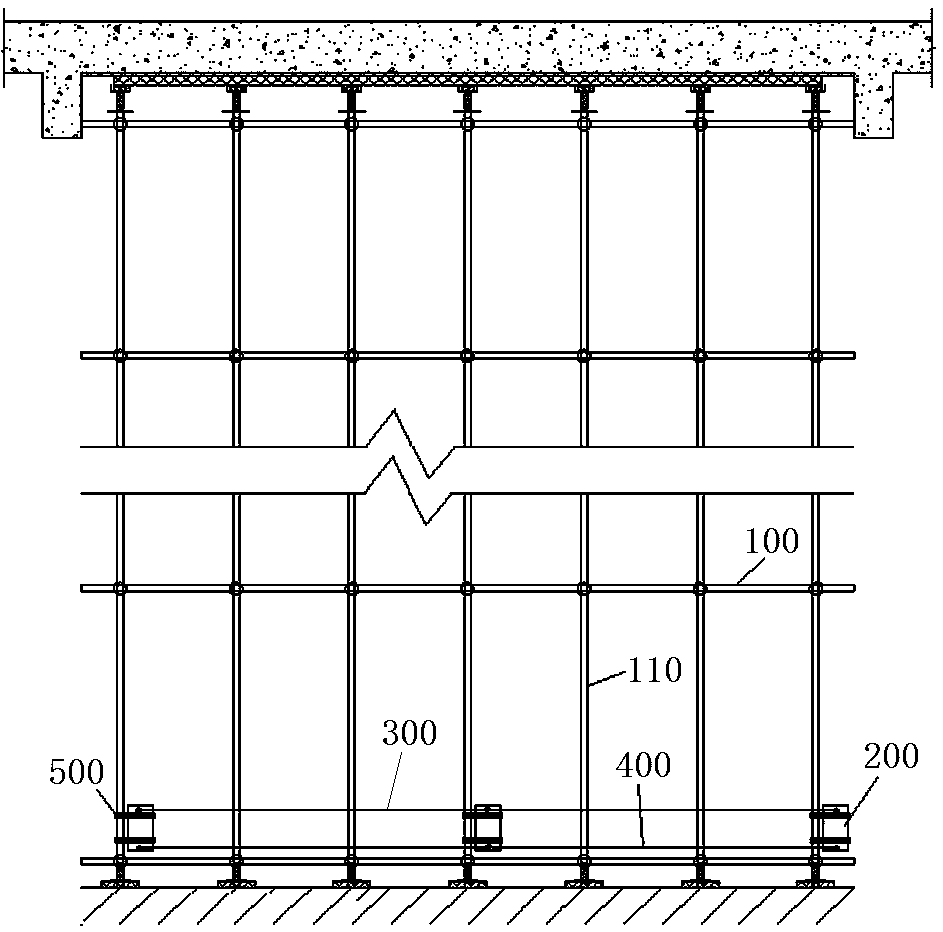

[0023] Embodiment two: if figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the fiber grating static level 200 is installed at the lower end of the pole, then the settlement monitoring value of the monitoring point at this time is mainly the deformation of the foundation under the column, and the monitoring value can be used for accurate It is difficult to judge the deformation of the formwork foundation accurately, but it is difficult to judge whether the erection quality of the formwork support frame is qualified, such as whether there is deformation of the frame caused by too large connection joints of vertical poles or loose connection of other components.

Embodiment 3

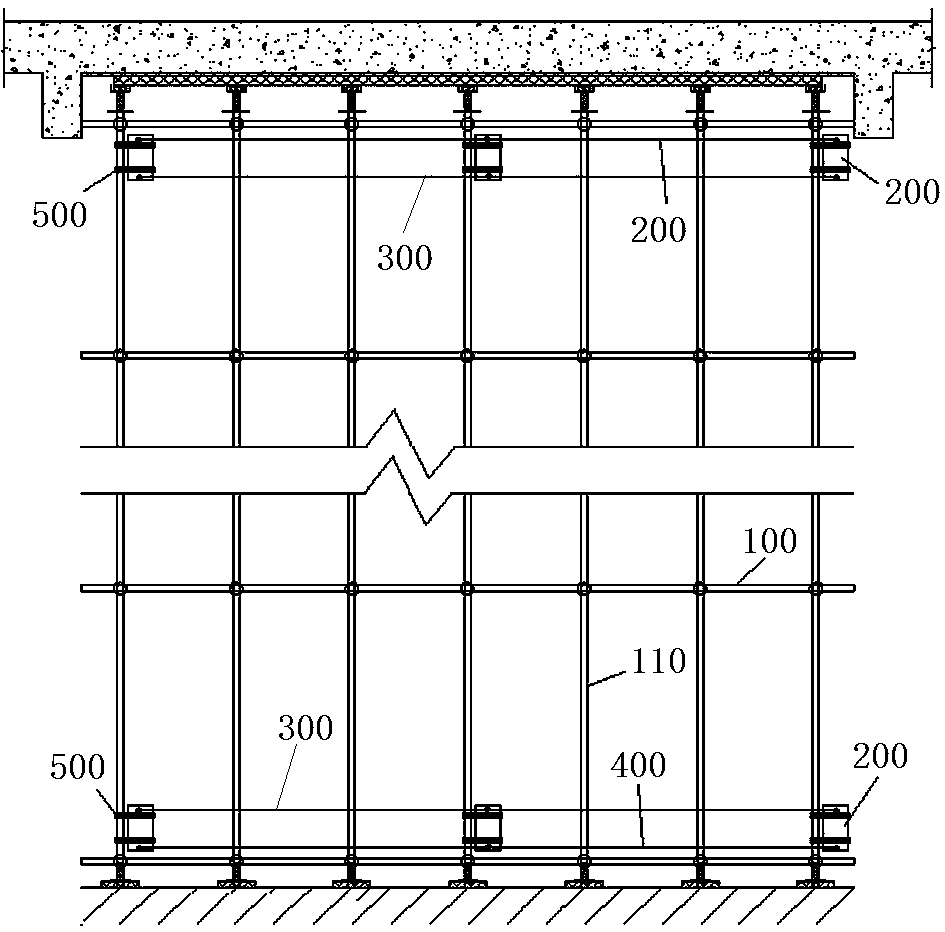

[0024] Embodiment three: as image 3 As shown, the difference between this embodiment and Embodiment 1 is that a fiber grating static level 200 is installed at the upper and lower ends of the column of the support frame, and all the fiber grating static levels positioned at the upper end of the vertical pole pass through the vent pipe 300 and the liquid. The tubes 400 are connected in series, and all the fiber grating static levels located at the lower end of the pole are also connected in series through the vent tube 300 and the liquid tube 400. This method will objectively capture and record the settlement deformation of the template support frame, and at the same time accurately The settlement caused by the deformation of the support frame and the deformation of the foundation can be obtained, which can be used to analyze the reasons for the abnormal internal stress of the support members and the abnormal operation of the high-support formwork, which is more conducive to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com