Tea processing equipment

A processing equipment and tea technology, applied in lighting and heating equipment, tea drying, tea treatment before extraction, etc., can solve problems such as affecting the quality of tea leaves, easy to mold and deteriorate, and achieve the effect of good drying and water removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is further described in detail through specific implementation methods:

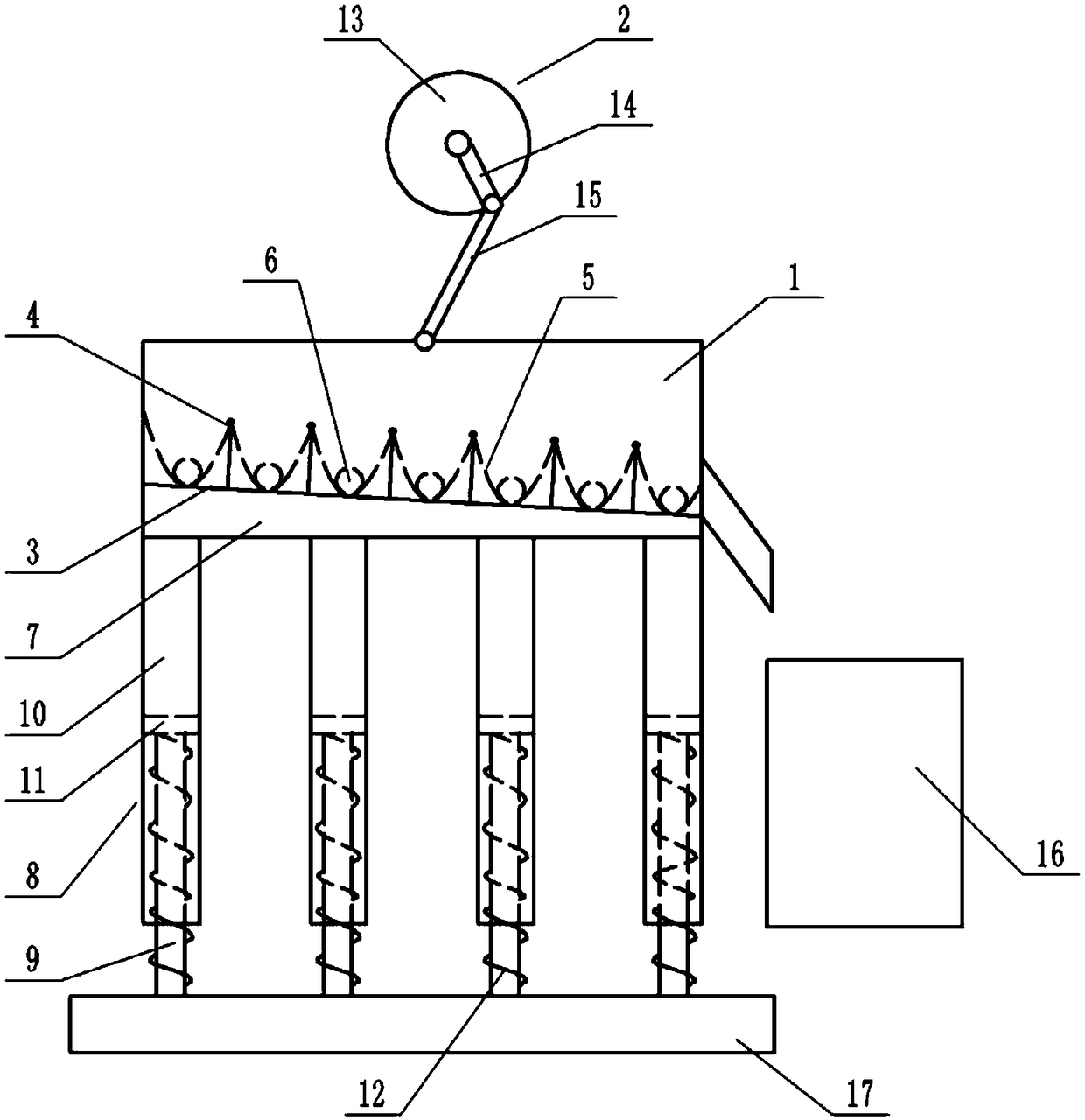

[0022] The reference signs in the drawings of the description include: drying box 1, rotary reciprocating mechanism 2, bearing plate 3, connecting rod 4, tea turning block 5, magnet block 6, air cavity 7, drying column 8, bearing rod 9, Hollow sliding rod 10, sliding plate 11, coil 12, rotating disc 13, first rod 14, second rod 15, tea collection box 16, bearing seat 17.

[0023] The embodiment of tea processing equipment is basically as attached figure 1 Shown: includes frame and motor, also includes drying box 1 that is slidably connected on the frame and rotary reciprocating mechanism 2 that can drive drying box 1 to move up and down reciprocatingly connected on the frame, and rotary reciprocating mechanism 2 is composed of Driven by a motor, the rotary reciprocating mechanism 2 includes a rotating disk 13 connected to the frame, a first rod 14 connected to the rotating disk 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com