Drying device used for producing plastic bottles

A drying device and plastic bottle technology, applied in the direction of drying gas arrangement, progressive dryer, drying solid materials, etc., can solve the problems of inability to dry moisture, etc., achieve the effect of easy maintenance, application and promotion, and avoid deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

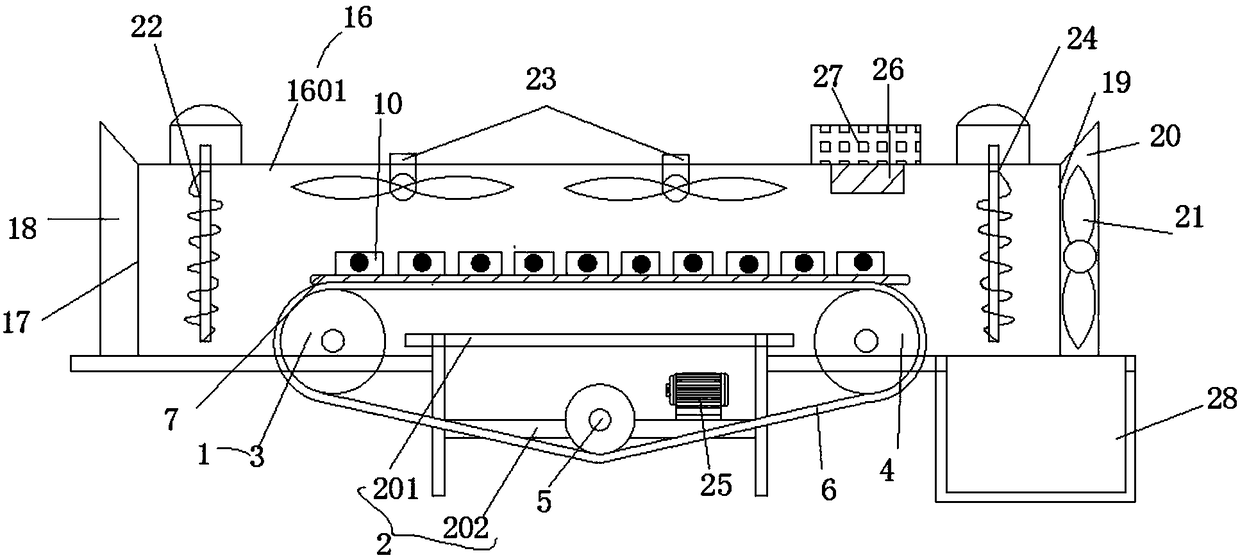

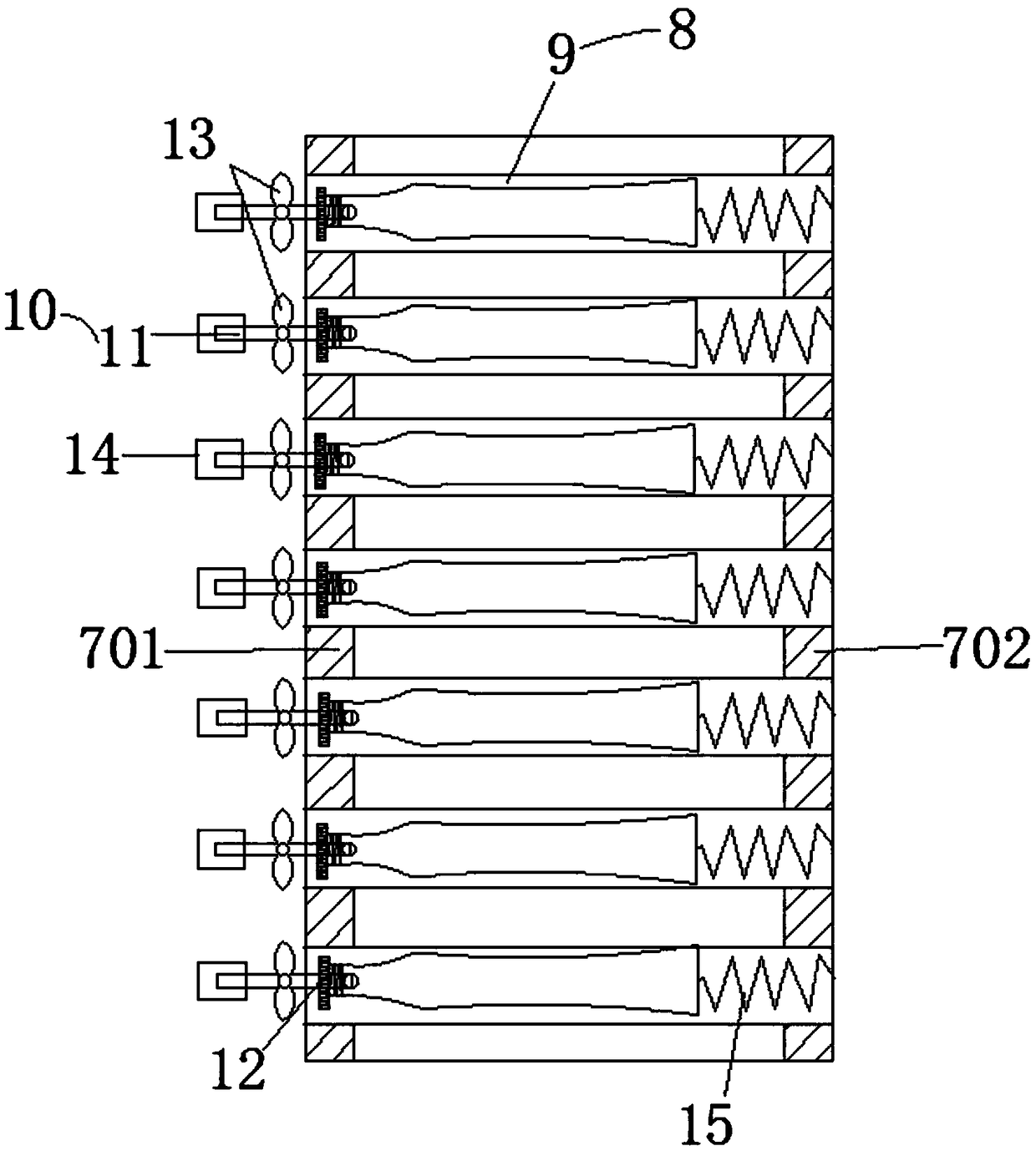

[0018] Embodiment 1: see figure 1 and figure 2 Now, a drying device for the production of plastic bottles provided by the present invention is described, which includes a conveying unit 1 for conveying bottles, and the conveying unit 1 is fixed on a supporting platform 2, and the supporting platform 2 includes a main supporting platform 201 and auxiliary support platform 202, the conveying unit 1 includes a driving wheel 3, a driven wheel 4 and a tensioning wheel 5, the driving wheel 3 and the driven wheel 4 are fixed on the main supporting platform 201, and the tensioning wheel 5 is fixed On the sub-support platform 202, a conveyor belt 6 is installed on the wheel surfaces of the driving pulley 3, the driven pulley 4 and the tension pulley 5, and a fixed plate group 7 is installed on the conveyor belt 6, and the fixed plate group 7 is arranged on Both sides of conveyer belt 6, it comprises left fixed plate 701 and right fixed plate 702, and the storage unit 8 that is used f...

Embodiment 2

[0019] Example 2: see figure 1 and figure 2 , as an improvement of the present invention, a motor 25 for powering the driving wheel 3 is installed on the auxiliary support platform 202 .

Embodiment 3

[0020] Embodiment 3: see figure 1 and figure 2 , as an improvement of the present invention, the tank body 9 is a tank body that penetrates up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com