Alkali-free wolfberry drying machine

A drying machine and Lycium barbarum technology, applied in local stirring dryers, static material dryers, dryers, etc., can solve problems such as unfavorable quality assurance of Lycium barbarum, low heat use efficiency, quality and color damage of Lycium barbarum, etc., to achieve Wide application range, long service life and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

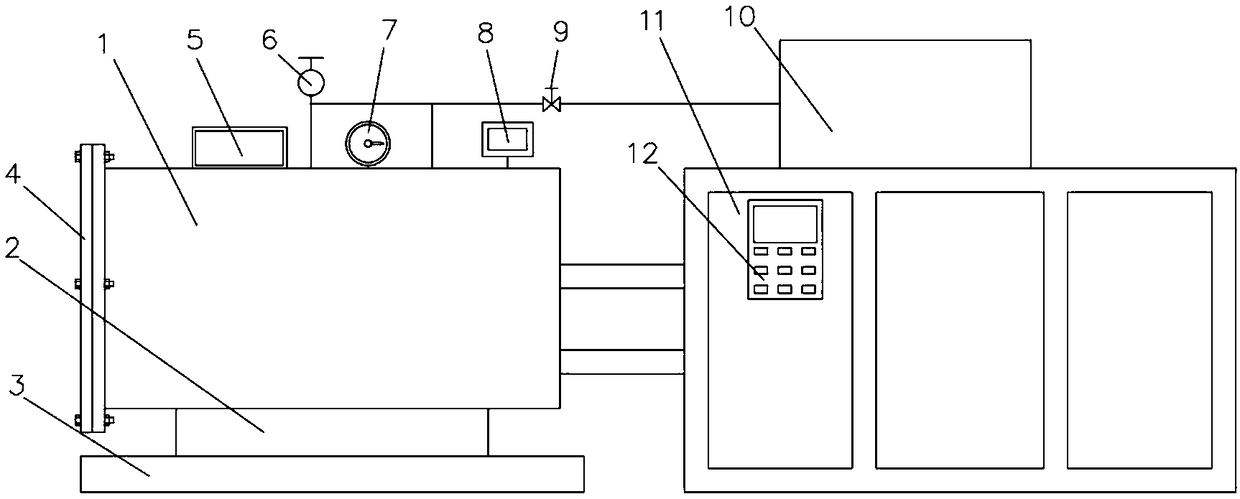

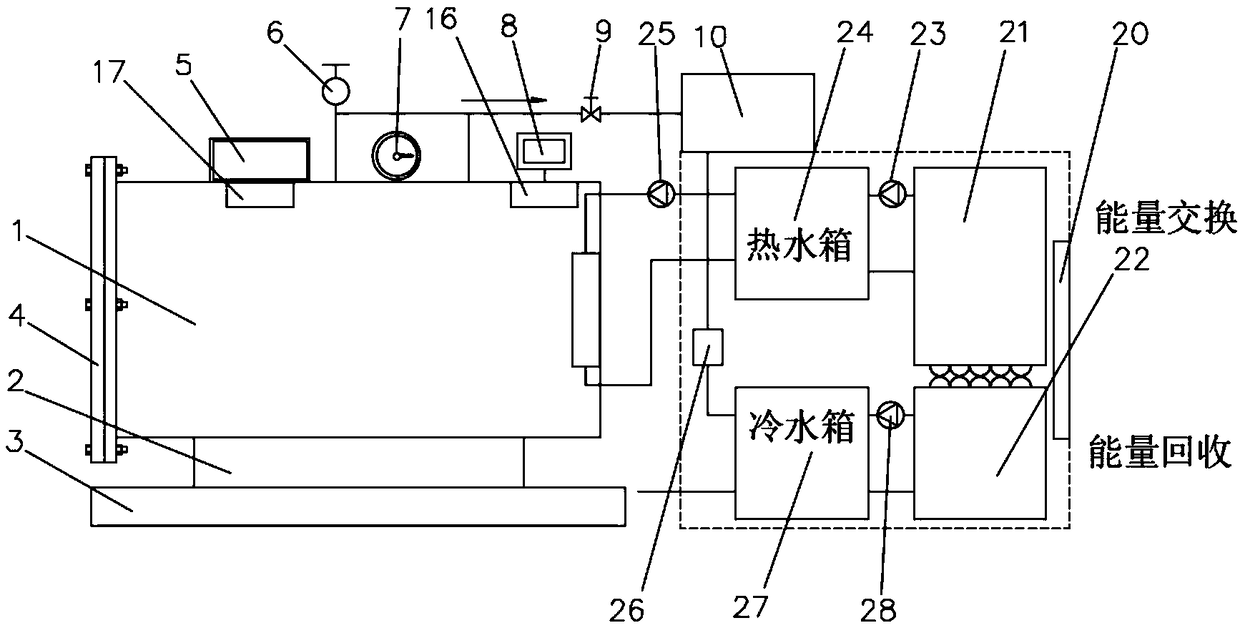

[0045] Example 1, such as Figure 1-2 Shown:

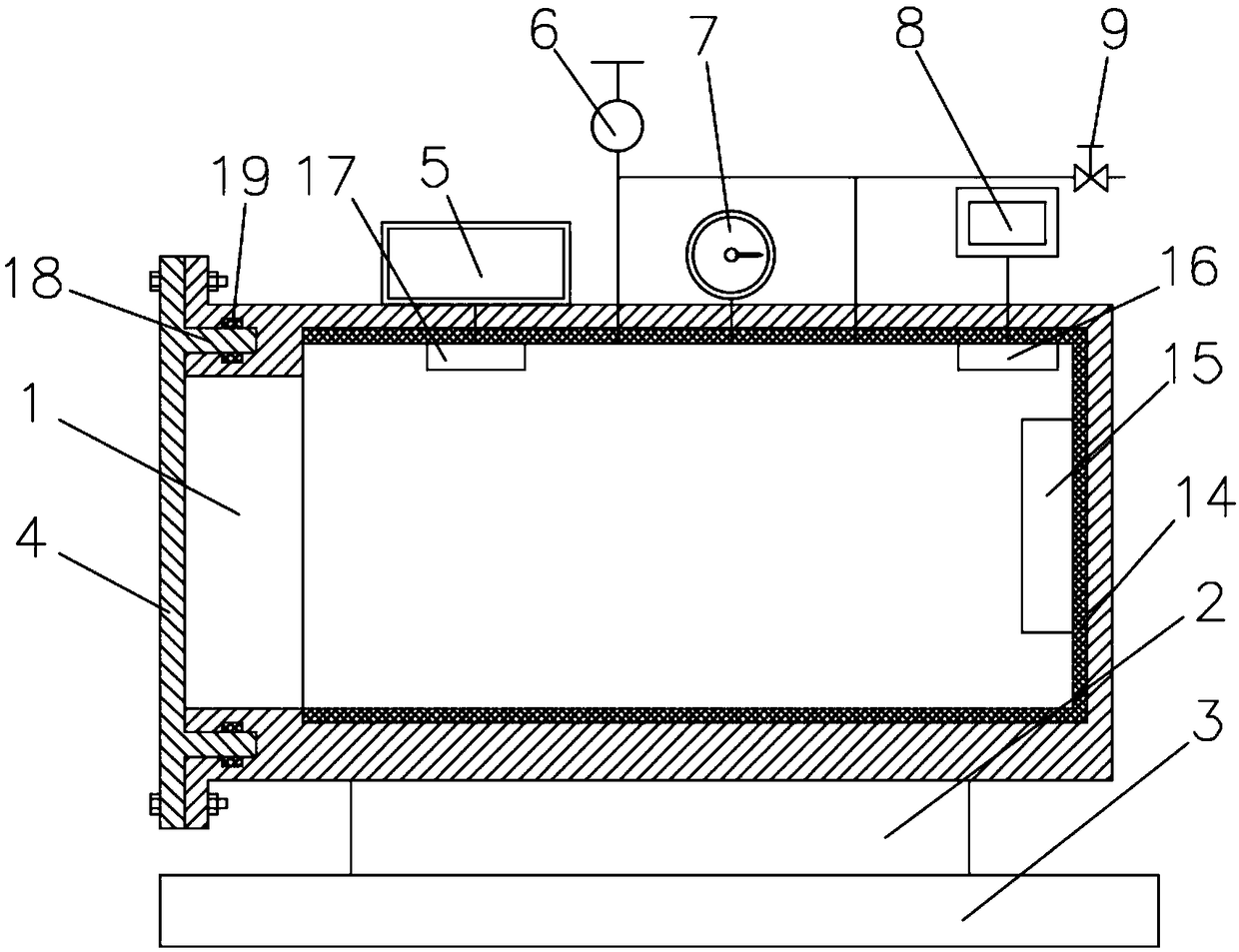

[0046] An alkali-free wolfberry dryer, comprising a box 11 with a cuboid structure, a controller 12, a drying chamber 1 with a cylindrical structure, and an energy switch 21 installed inside the box 11, an energy recovery machine 22, a cold water tank 27, hot water Box 24 and Roots vacuum pump 26; the energy exchange 21 and the energy recovery machine 22 are connected to each other through a heat exchanger to form an energy exchange group; the right side wall of the inner cavity of the chassis 11 is fixedly installed with a Heat electric auxiliary heating device 20;

[0047] The left end opening of the drying chamber 1 is equipped with a disc-shaped end cap 4, and the inner surface of the end cap 4 is provided with a ring-shaped connecting ring 18; the outer edge of the end cap 4 and the opening of the left end of the drying chamber 1 The outer edges are matched with connecting flanges, and the end cover 4 and the drying chamber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com