CO2 gas shielded welding method

A technology of gas shielded welding and welding methods, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., and can solve problems such as poor formation of gas shielded welding seams, unreasonable angles between welding wire and weld bead, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

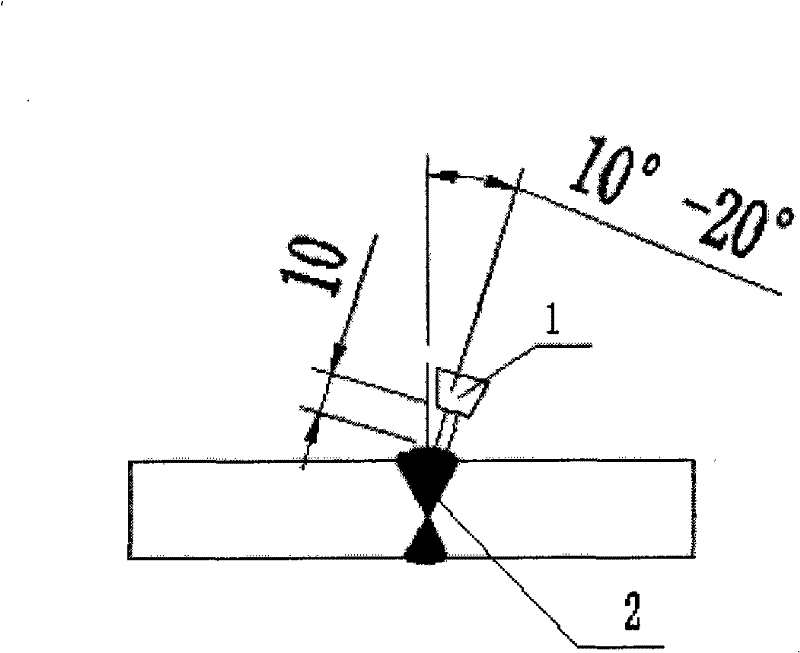

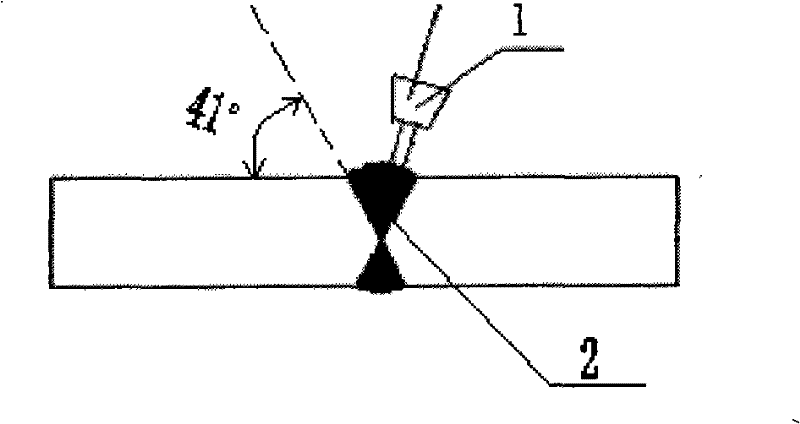

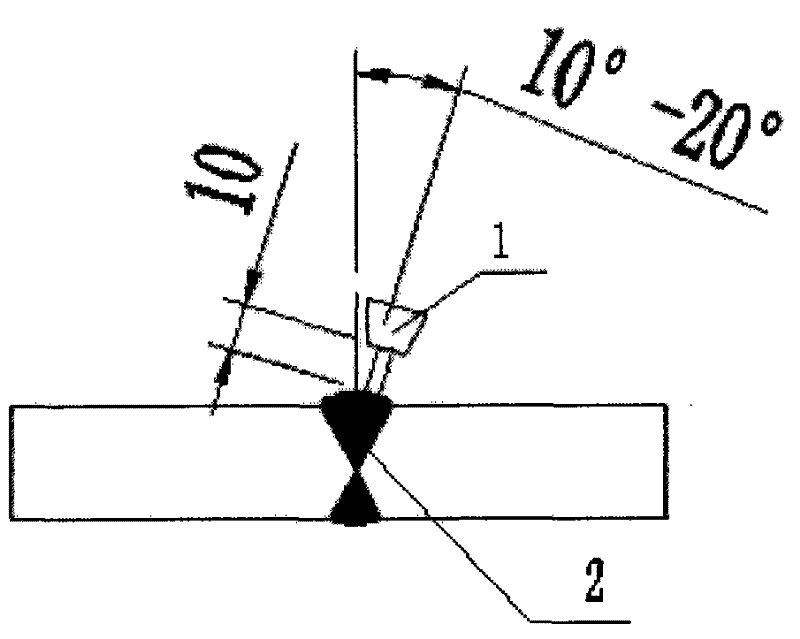

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] During operation, use ordinary flat outer characteristic welding power supply, connect the contact tip, welding wire and the positive pole of the welding power supply through the cable and the conductive mechanism of the welding torch, and connect the workpiece and the negative pole of the welding power supply through the cable (that is, the polarity of the power supply adopts DC Reverse connection). The welding wire is arranged in the middle of the groove through the welding torch adjustment mechanism installed on the welding trolley, the height of the contact tip from the workpiece is adjusted through the welding torch height adjustment mechanism, and the welding speed is adjusted by adjusting the walking speed of the welding trolley. Also, avoid welding on rainy, snowy, windy or humid cloudy days, or not welding important welds.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com