Cooling device of high temperature corrosion medium valve

A high-temperature corrosion and cooling device technology, applied in household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of inability to quickly dissipate heat and cool down, limited heat dissipation efficiency, etc., to achieve a smooth temperature drop process, ensure fluidity, and accelerate The effect of the cooling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

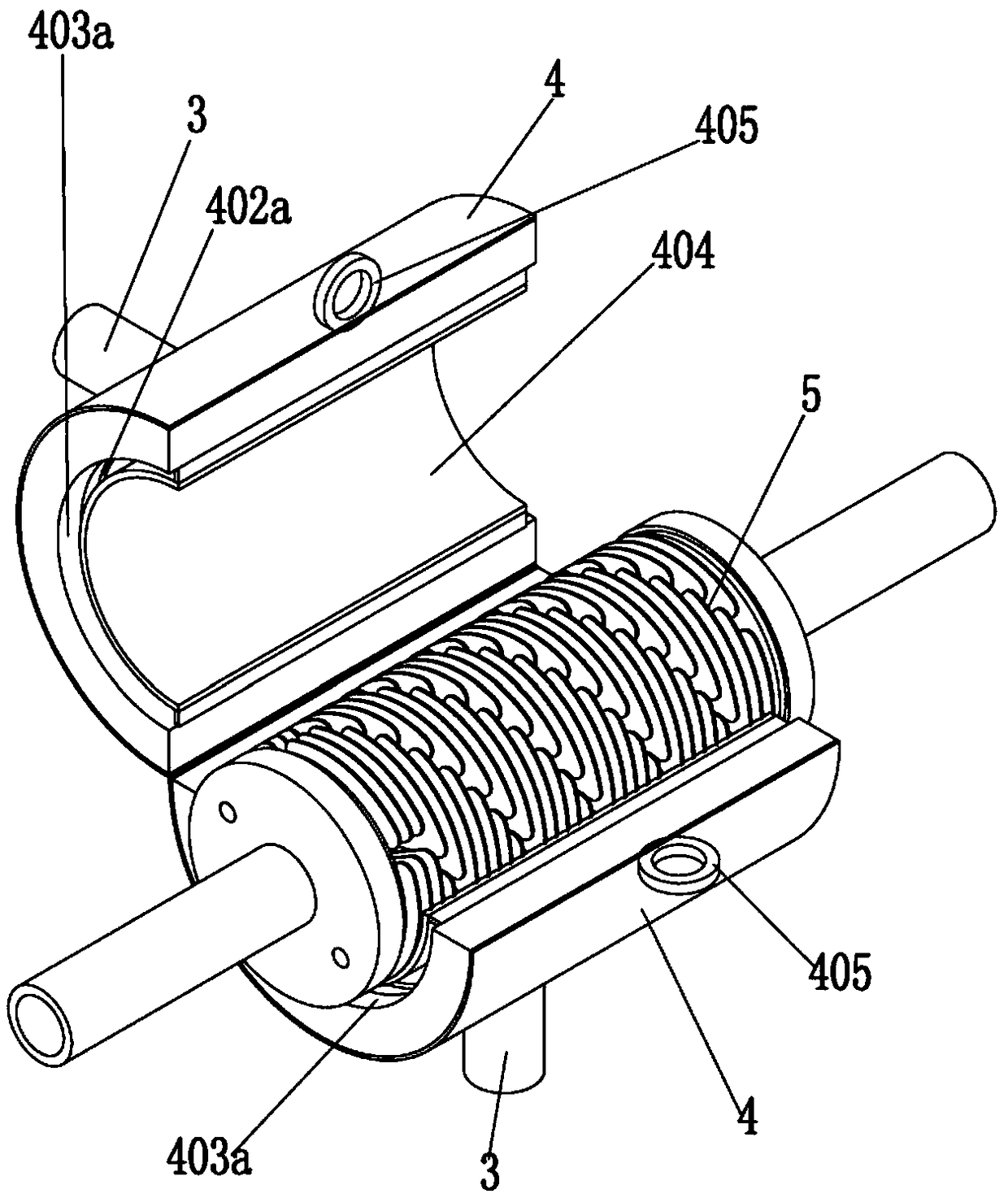

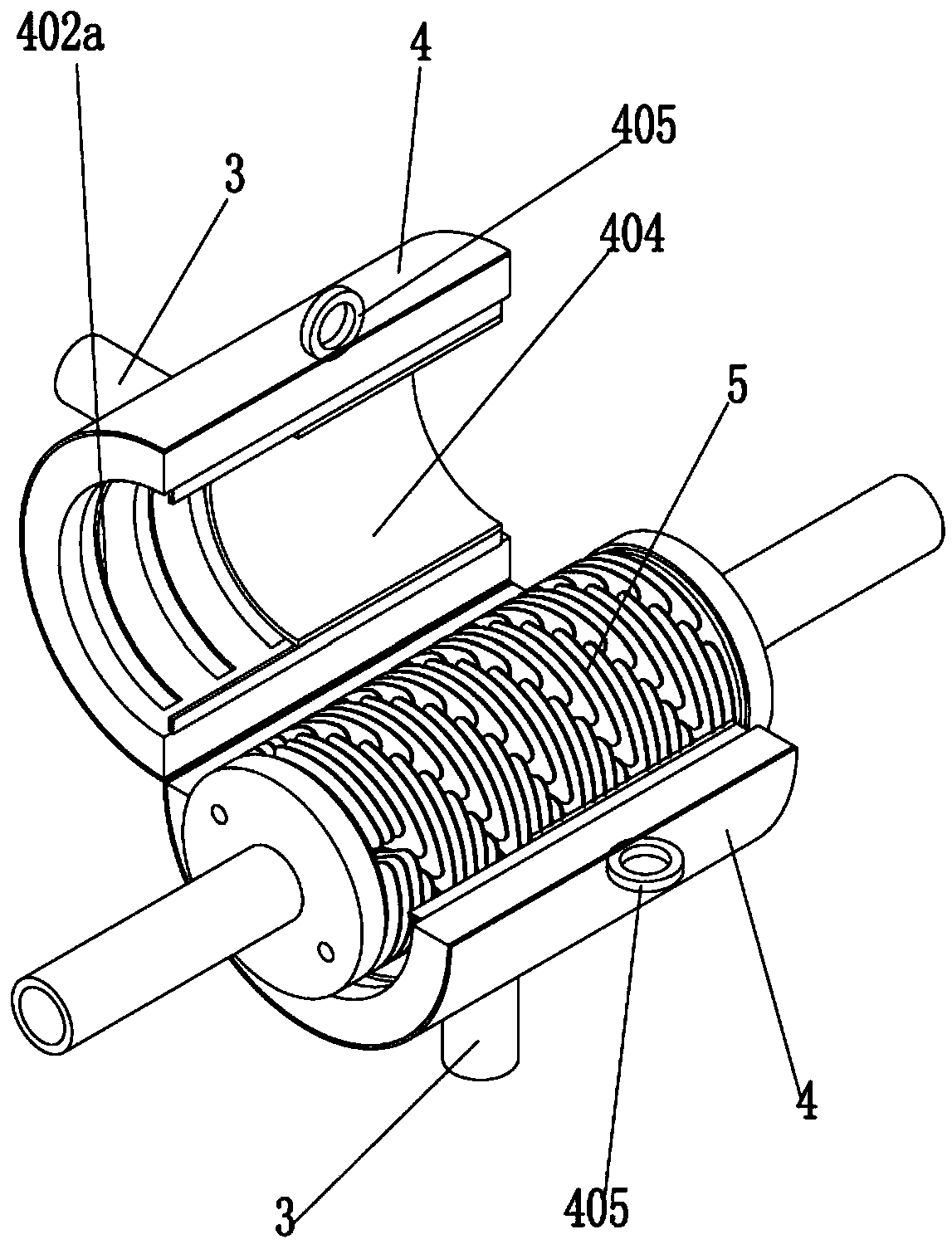

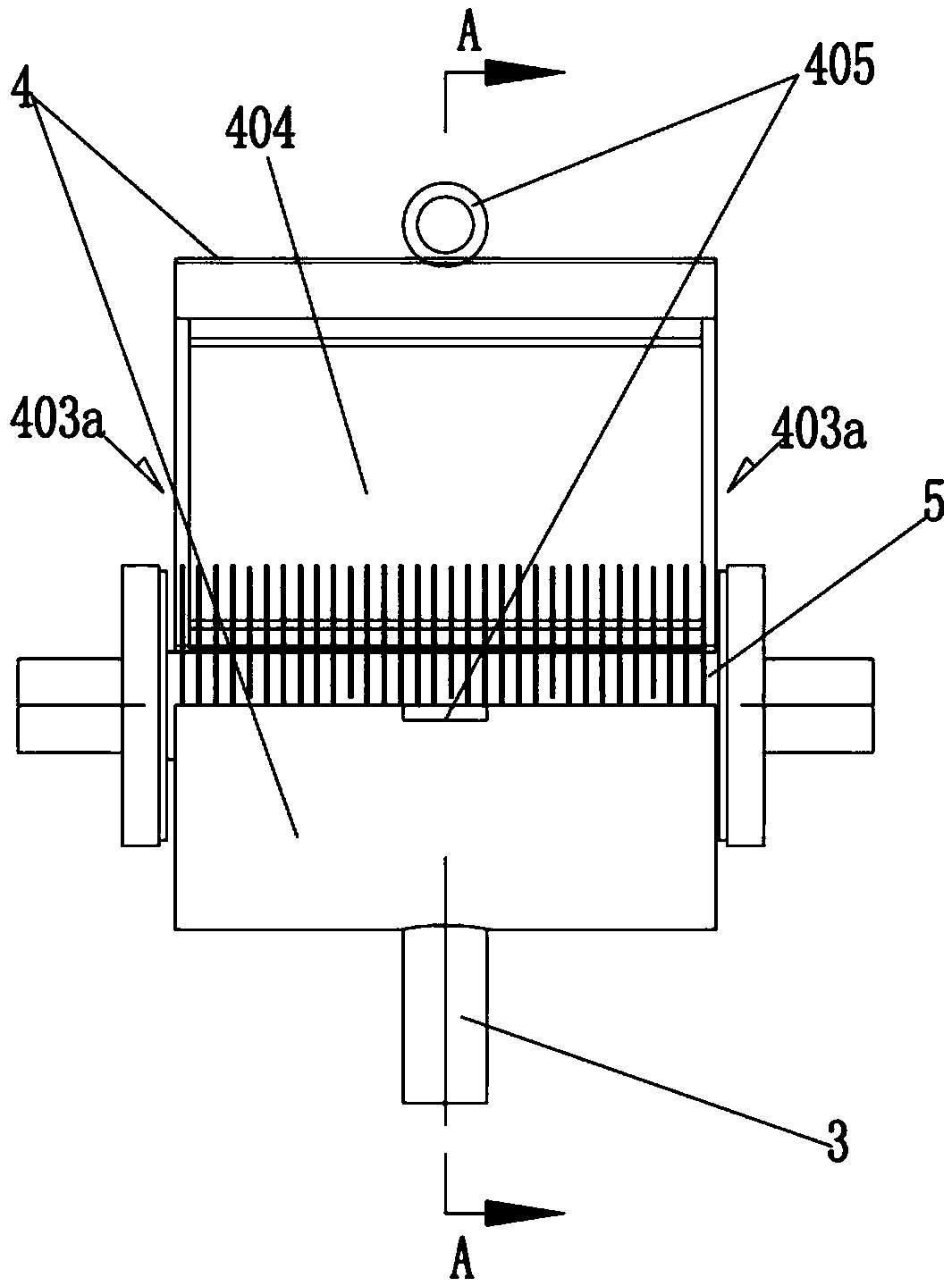

[0022] combine figure 1 , 5 As shown, a cooling device for a high-temperature corrosive medium valve includes a blower 1, a delivery pipeline, and two half-shell seats 4 with a hollow shell structure.

[0023] The two half-shells 4 are detachably assembled together and together surround the valve 5. The half-shells 4 include a heat exhaust chamber 403, and both ends of the heat exhaust chamber 403 are provided with air outlet openings 403a connected to the outside atmosphere. , two outlet openings 403a are arranged axially along the valve 5 .

[0024] The air outlet of the blower 1 is in communication with the heat exhaust chambers 403 of the two half-shells 4 through the delivery pipeline.

[0025] The inner side of the above-mentioned half-shell seat 4 is provided with an inner plate 404 made of an arc-shaped plate structure and made of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com