Circulating fluidized bed boiler with independent double flues

A circulating fluidized bed and double flue technology, which is applied in fluidized bed combustion equipment, fuel burning in a molten state, lighting and heating equipment, etc., can solve problems such as uneven gas-solid flow, and reduce the risk of deformation and explosion , Improve thermal efficiency and reduce emission control costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

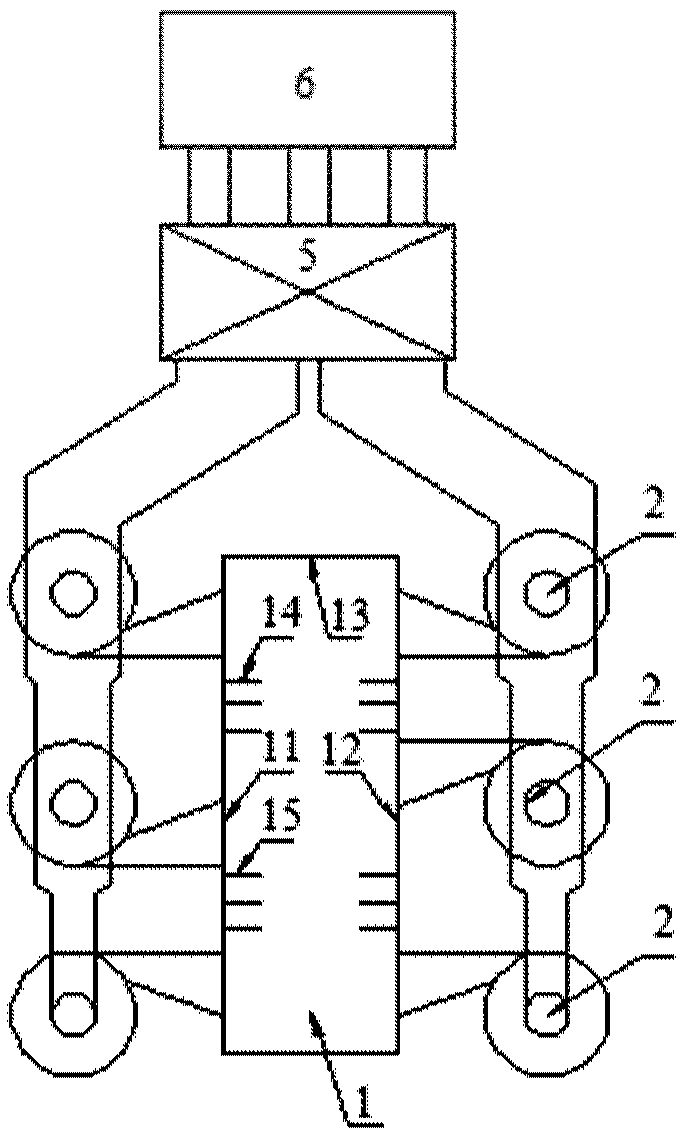

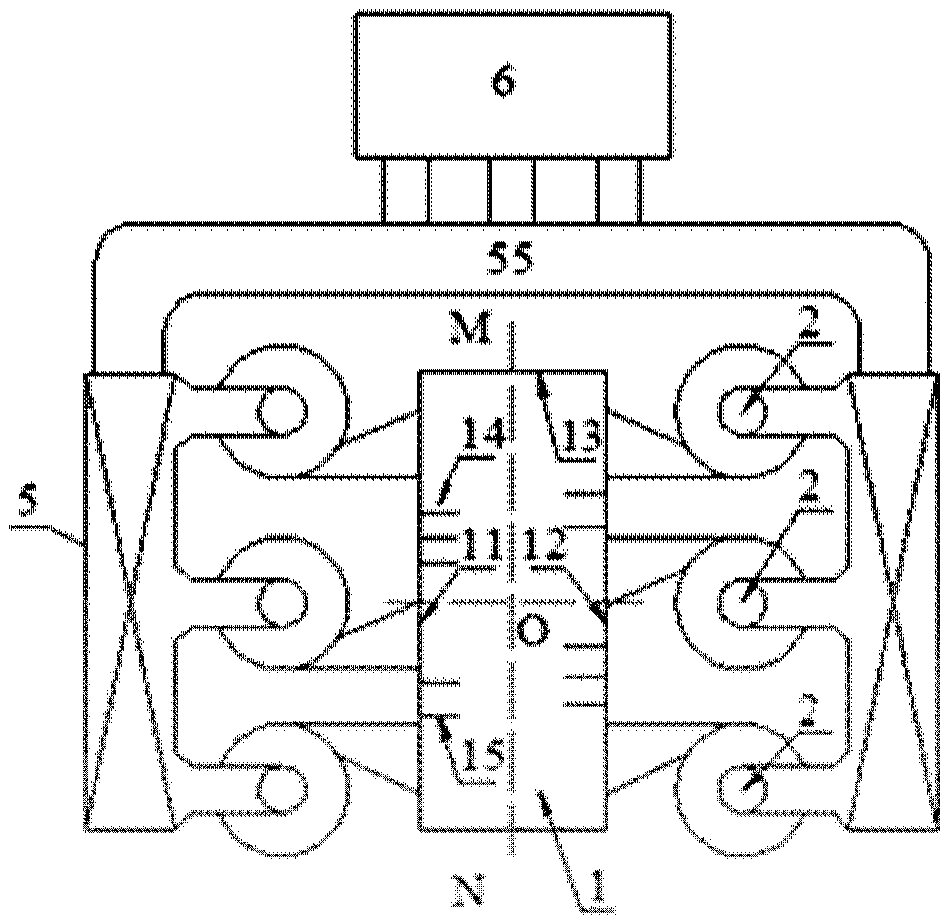

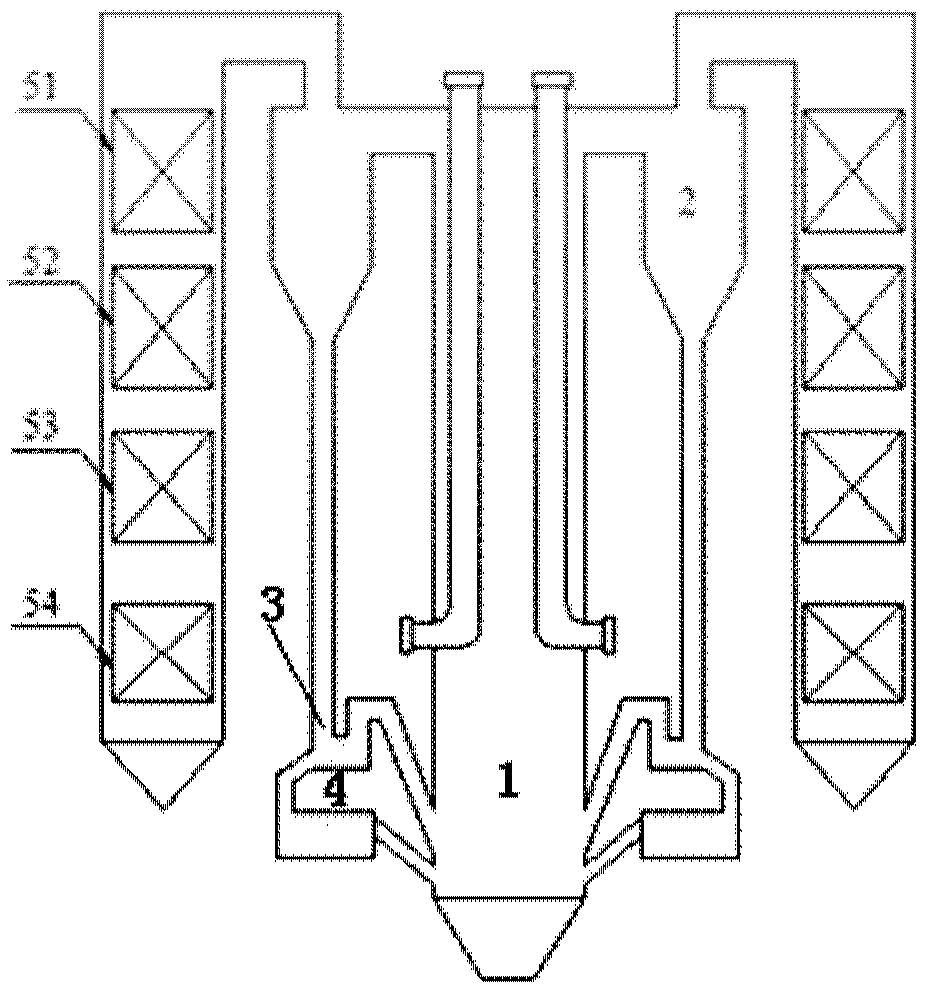

[0048] In the prior art, when the outlet flue structures of multiple cyclone separators on the same side are different in flue gas resistance, the separation efficiencies of multiple cyclone separators on the same side will be different, resulting in the difference between multiple circulation loops on the same side. The amount of circulating ash between the furnaces is different, which eventually leads to a serious uneven distribution of bed temperature along the width direction of the long side of the furnace. figure 1 It is a schematic top view of a circulating fluidized bed boiler in the prior art, such as figure 1As shown, it connects the outlet flues of the three cyclone separators on the same side along the direction from the front wall to the rear wall and then connects with the tail flue inlet located outside the rear wall of the furnace. For the outlets of the above multiple cyclone separators The layout of the tail flue, due to the different flue structures of multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com