Gear with pitted end face

A technology of gears and pits, applied in the direction of elements with teeth, belts/chains/gears, gear lubrication/cooling, etc., can solve the problems of tooth heel fracture, gear deformation, vibration increase, etc., to reduce gear temperature, The effect of reducing weight and reducing air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following examples.

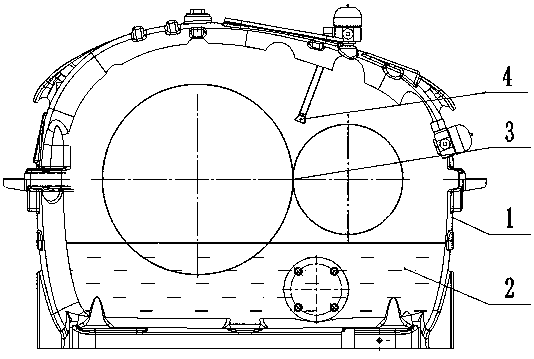

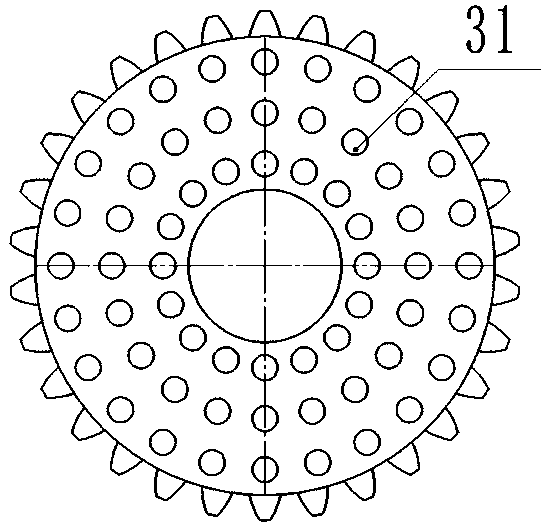

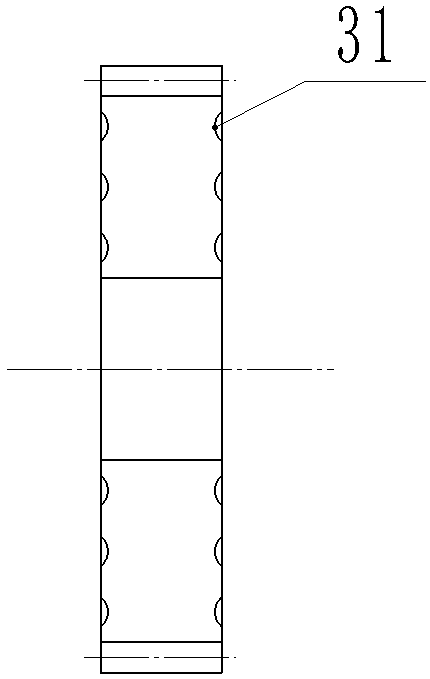

[0016] like Figure 1-3 As shown, for a gear with dimples on the end face, gear surface dimples 31 are provided on the surface of the gear pair 3;

[0017] The lubricating oil 2 is arranged in the reducer housing 1 , the gear pair 3 is submerged in the lubricating oil 2 , and the lubricating oil 2 is sprayed onto the gear pair 3 through the lubricating oil nozzle 4 .

[0018] The gear surface pits 31 are evenly distributed on the gear pair 3 in a circumferential shape, the diameter of the gear surface pits 31 is 10-50mm, and the depth is 2-5mm.

[0019] The above are only preferred specific implementations of the present invention. These specific implementations are all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com