Multi-coal seam gas pressure measuring device and measuring method in single drill hole

A technology of gas pressure and measurement devices, which is applied in the directions of measurement, earthwork drilling, wellbore/well components, etc., which can solve the problems of long measurement period, high cost, complicated operation process, etc., and achieve the reduction of labor intensity and simple measurement process , the effect of saving measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

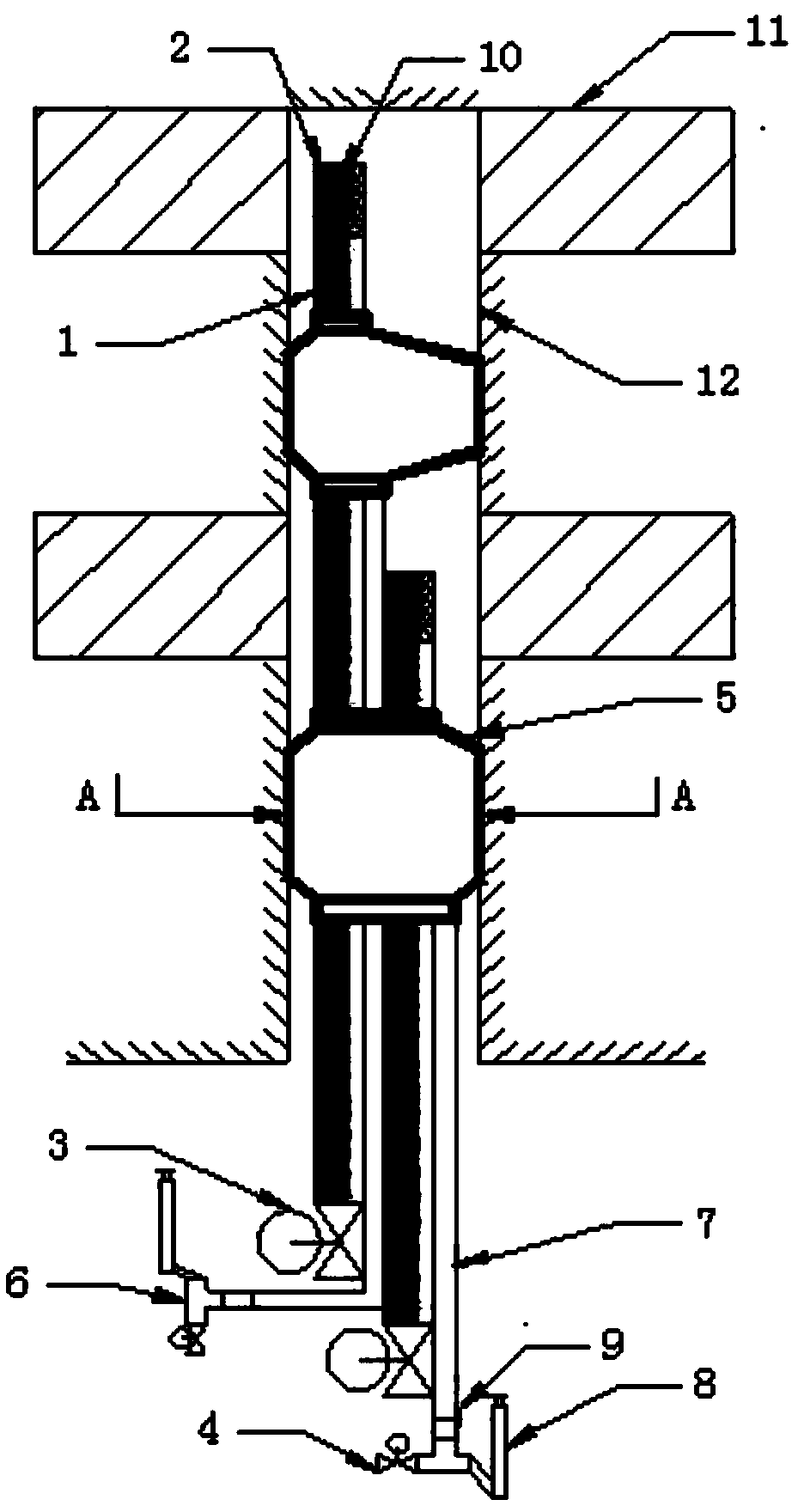

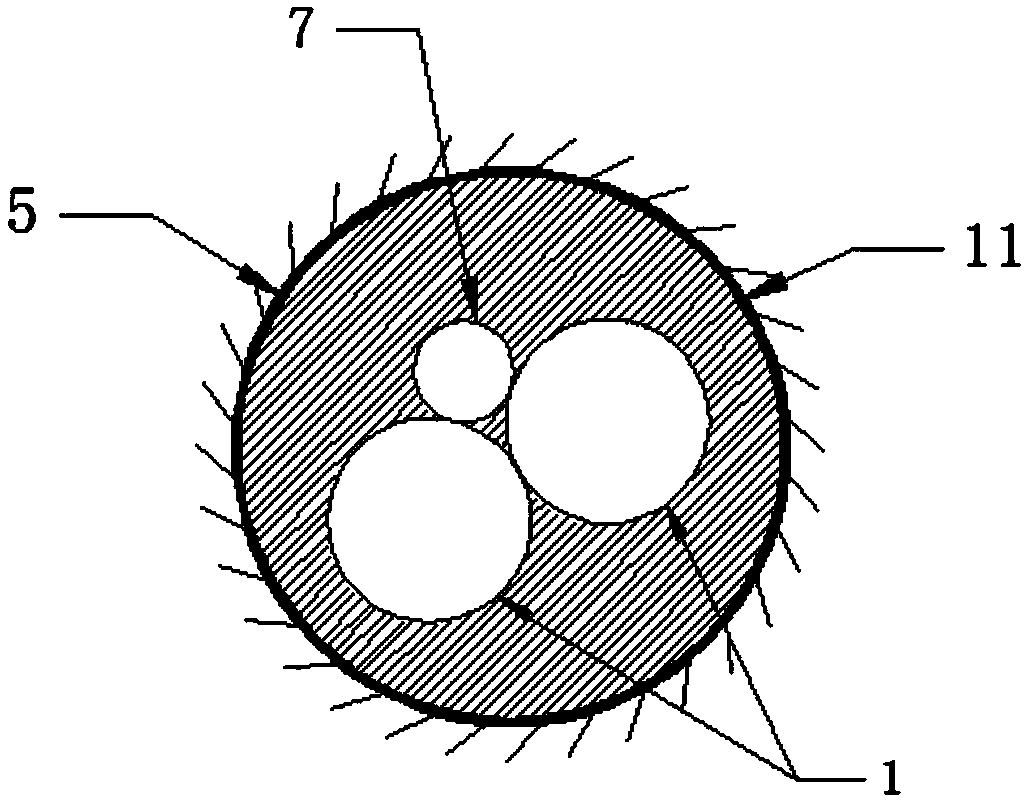

[0021] Below in conjunction with accompanying drawing and measure 2 layers of coal embodiment the present invention is described in detail:

[0022] A device and method for measuring gas pressure in multiple coal seams in a single borehole, comprising a pressure measuring tube 1, a barbed wire cover 2, a pressure measuring gauge 3, a pressure gauge 4, a sealing capsule 5, a tee 6, an inflatable tube 7, and an air pump 8 Composed of a gas stop valve 10, the top of the pressure measuring tube 1 is punched with a pressure measuring hole 9 and connected to the wire mesh cover 2, the bottom end is connected to the pressure measuring gauge 3, the sealing capsule 5 is airtightly wrapped outside the pressure measuring tube 1, and the sealing capsule 5 is connected to inflatable Pipe 7, the bottom end of inflation pipe 7 is connected with stop valve 10 and then connected with tee 6, and the other two ends of tee 6 are connected with pressure gauge 4 and pump 8.

[0023] The method for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com