A steel pipe friction composite damper

A technology of composite damping and steel pipes, which is applied in the direction of building types, buildings, building components, etc., can solve the problems of poor durability, low cost performance, high material requirements, etc., and achieve easy industrial production, clear force mechanism and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

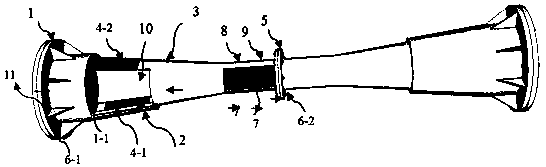

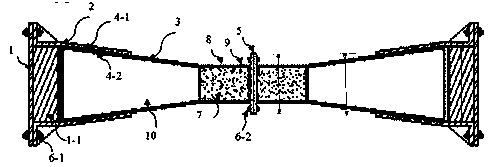

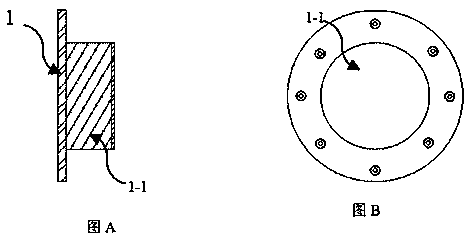

[0027] Embodiment 1: as Figure 1~3 As shown, the steel pipe friction composite damper includes two damping parts, the two damping parts have the same structure, and each damping part includes a connecting plate 1, a rubber block 1-1, an outer steel pipe 2, an inner steel pipe 3, and an outer steel pipe Friction material 4-1, inner steel pipe friction material 4-2, flange plate Ⅰ5, 8 bolts Ⅰ6-1, 8 bolts Ⅱ6-2, concrete cavity 7, through hole Ⅰ8, through hole Ⅱ9, cavity 10, method Lanban II 11;

[0028] One end of the outer steel pipe 2 is connected to the flange plate II11, the connecting plate 1 is connected to the flange plate II11 through 8 bolts I6-1, the inner steel pipe 3 is installed inside the outer steel pipe 2, and the outer steel pipe 2 , the inner steel pipe 3 are variable-section steel pipes, the outer diameters of the outer steel pipe 2 and the inner steel pipe 3 are successively reduced from one end to the other, and the large outer diameter end of the inner ste...

Embodiment 2

[0034] Embodiment 2: The structure of this embodiment is the same as that of Embodiment 1, except that the outer steel pipe friction material 4-1 is NAO type friction material, and the inner steel pipe friction material 4-2 is rubber.

[0035] When the damper of the present invention is assembled, a damping part is first assembled arbitrarily, and the end of the inner steel pipe 3 with a smaller diameter can be penetrated from the end with a larger diameter of the outer steel pipe 2, and then the circular rubber block 1-1 is installed, and then the The connecting plate 1 and the flange plate Ⅱ11 are connected with 8 bolts Ⅱ6-2, and the 8 bolts Ⅱ6-2 are tightened, and then another damping part is assembled, and finally the two flange plates Ⅰ5 of the two damping parts are passed through 8 Bolt Ⅱ6-2 is fixedly connected, and then the inner steel pipe 3 is pulled out for a certain distance along the axial direction of the damper, so that the inner steel pipe 3 and the outer steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com