Diamond tool with metallized diamond surface and preparation method thereof

A diamond tool and surface metal technology, which is applied in the field of diamond tool preparation, can solve the problems of reducing the sharpness of diamond and effective utilization rate, insufficient holding force of matrix powder on diamond, and reduced service life of tools, so as to improve effective utilization rate, Improvement of sharpness and life, and the effect of improving grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

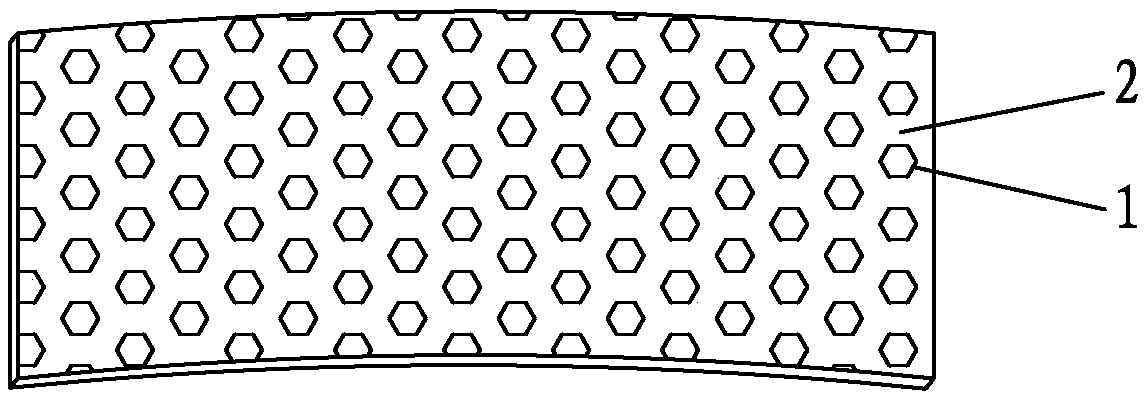

[0036] This case involves a diamond tool preparation method for diamond surface metallization, including the following steps:

[0037] 1) Select a diamond tool matrix, which is a pre-alloyed powder of a specific metal series, and the specific metal includes at least two metal components;

[0038] The selected diamond tool matrix powder can be the same pre-alloyed powder as the normal tool.

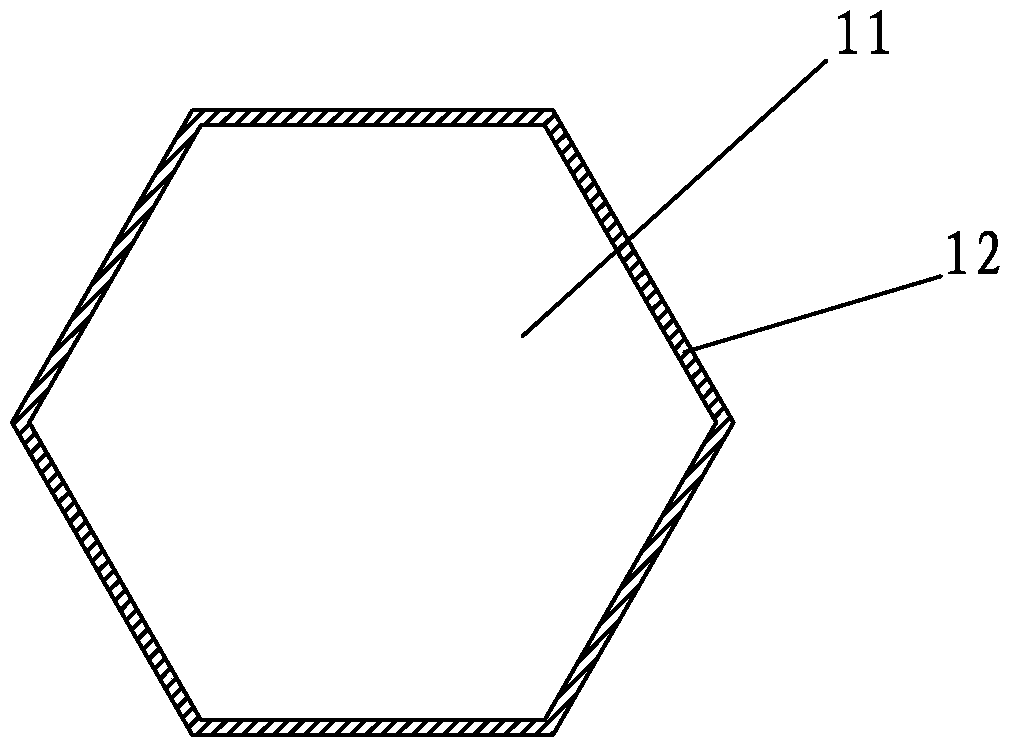

[0039] 2) Carry out titanium powder coating treatment on the diamond surface first, then carry out sequential coating treatment of at least one metal other than titanium metal, the at least one metal is selected from the above-mentioned at least two metal components;

[0040] For example, if the carcass of diamond tools is selected as iron-copper-nickel-tin series, at least one metal can be selected from iron, copper, nickel, and tin; the carcass formed by the selected metal powder must have a bending strength of more than 800KN. It is necessary to form a mechanical bite force on the diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com